Method for preparing 2,3,3,3-tetrafluoropropene

A technology of tetrafluoropropene and tetrachloropropene, applied in 2 fields, can solve problems such as many reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

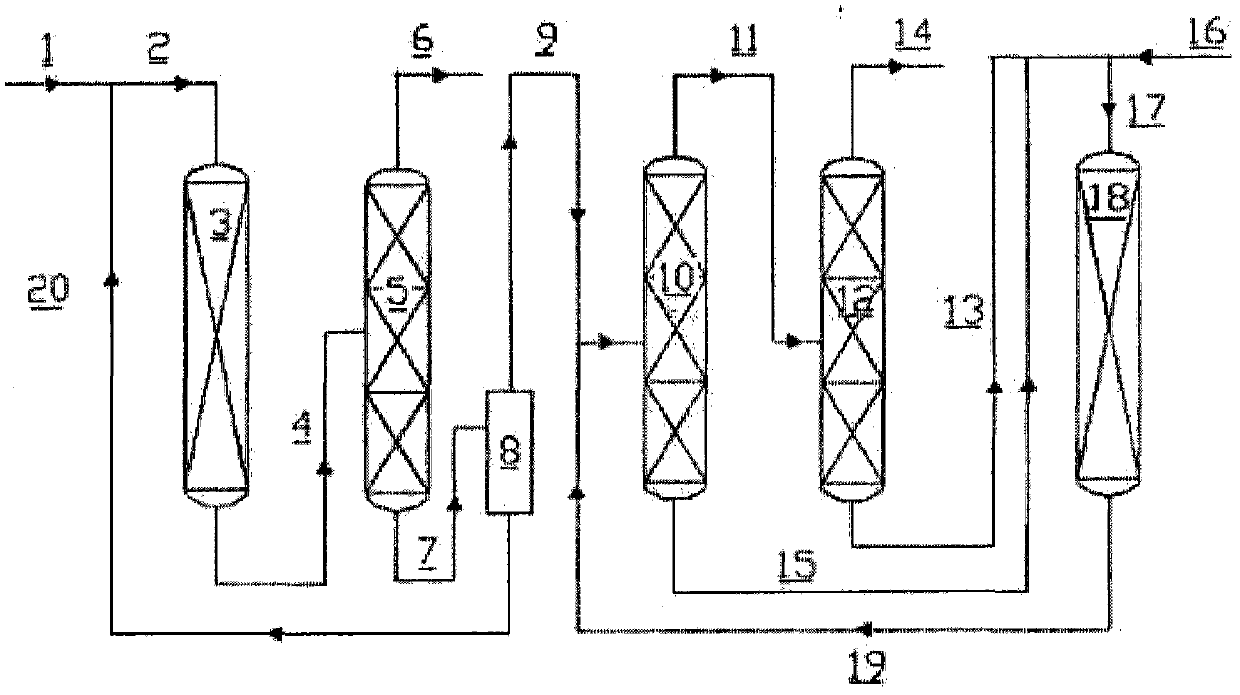

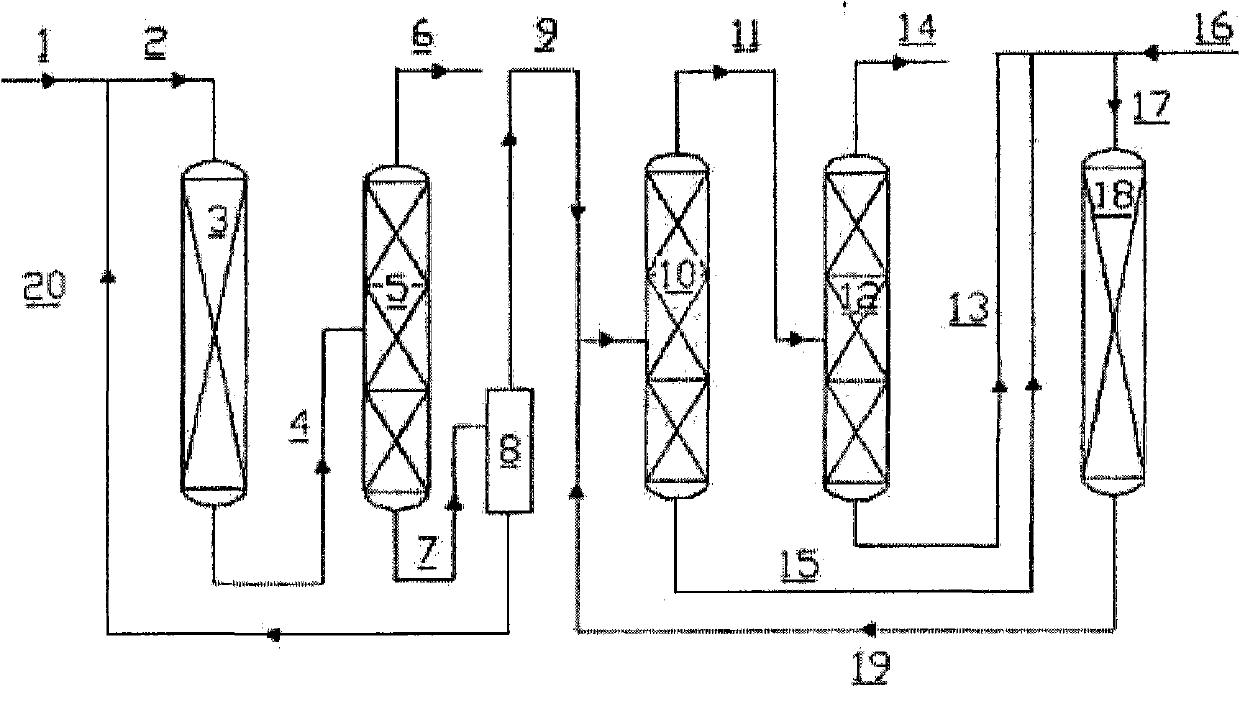

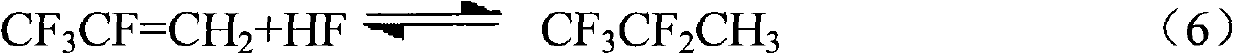

Method used

Image

Examples

Embodiment 1

[0035] Add 60 milliliters of chromium-based fluorination catalyst containing Al, Zn, Mg and Ni into a carbon steel pipe with an inner diameter of 38 mm. The preparation method of the catalyst is shown in Chinese patent CN1651137A. The temperature of the first reactor was raised to 260°C, and HF and 1,1,1,2,2-pentachloropropane (HCC-240ab) were introduced to react, the molar ratio of HF to HCC-240ab was controlled to be 10, and the contact time was 6 seconds, the reaction pressure is 0.1MPa, and after 20 hours of reaction, the reaction product is washed with water, washed with alkali, and dried with alkali to remove HCl and HF. The composition of the organic matter in the reaction product is analyzed by gas chromatography. The results are shown in Table 1.

Embodiment 2

[0037] The operation was basically the same as in Example 1, except that the reaction temperature of the first reactor was changed to 220° C., the results are shown in Table 1.

Embodiment 3

[0039] The operation was basically the same as in Example 1, except that the reaction temperature of the first reactor was changed to 300° C., the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com