Catalyst for synthesizing tirbutyl citrate and preparation method thereof

A technology of tributyl citrate and catalyst, which is applied in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of poor thermal stability of the carrier, easy loss of active components, and low conversion rate of raw materials. , to achieve the effect of not easy to lose and good reuse performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

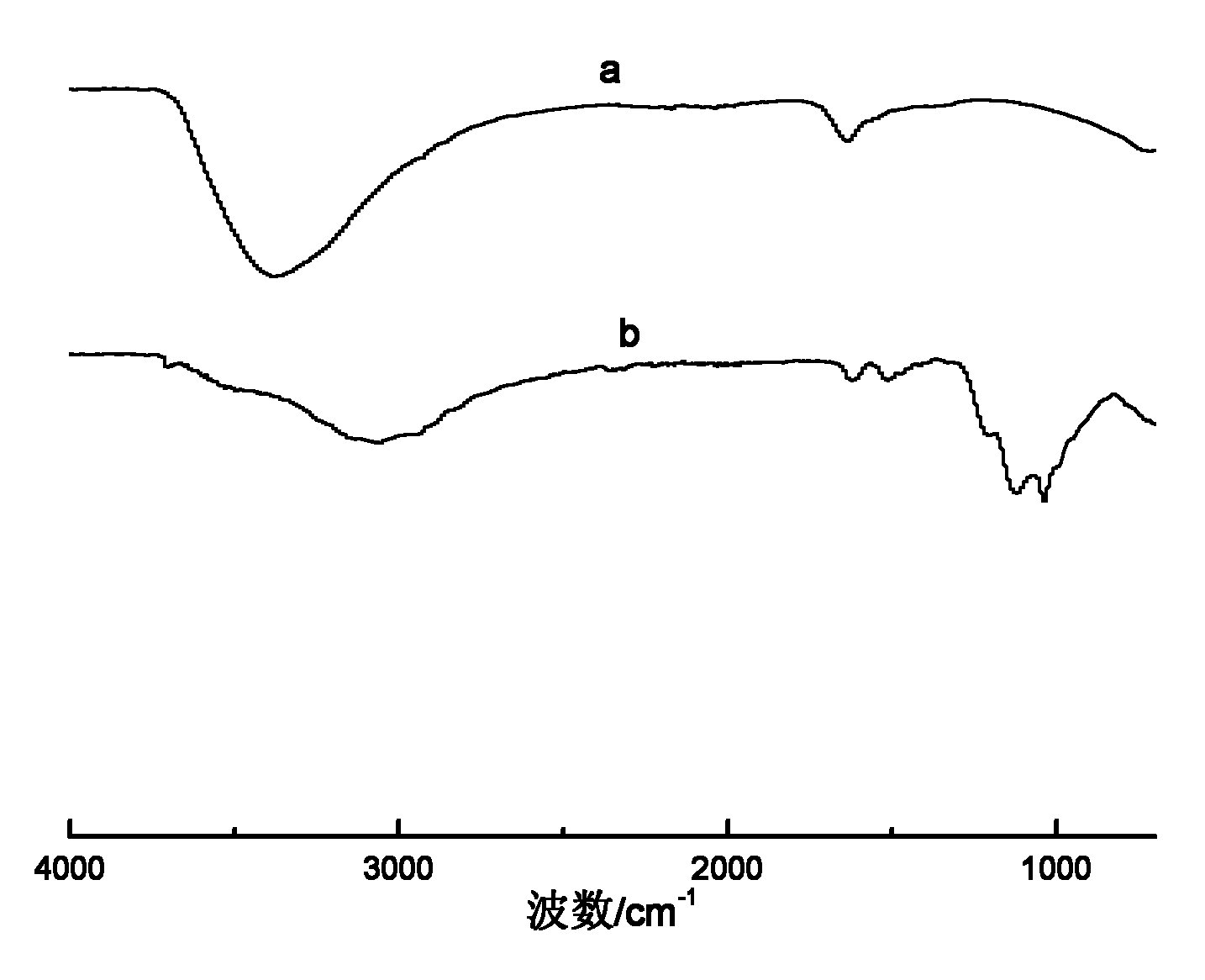

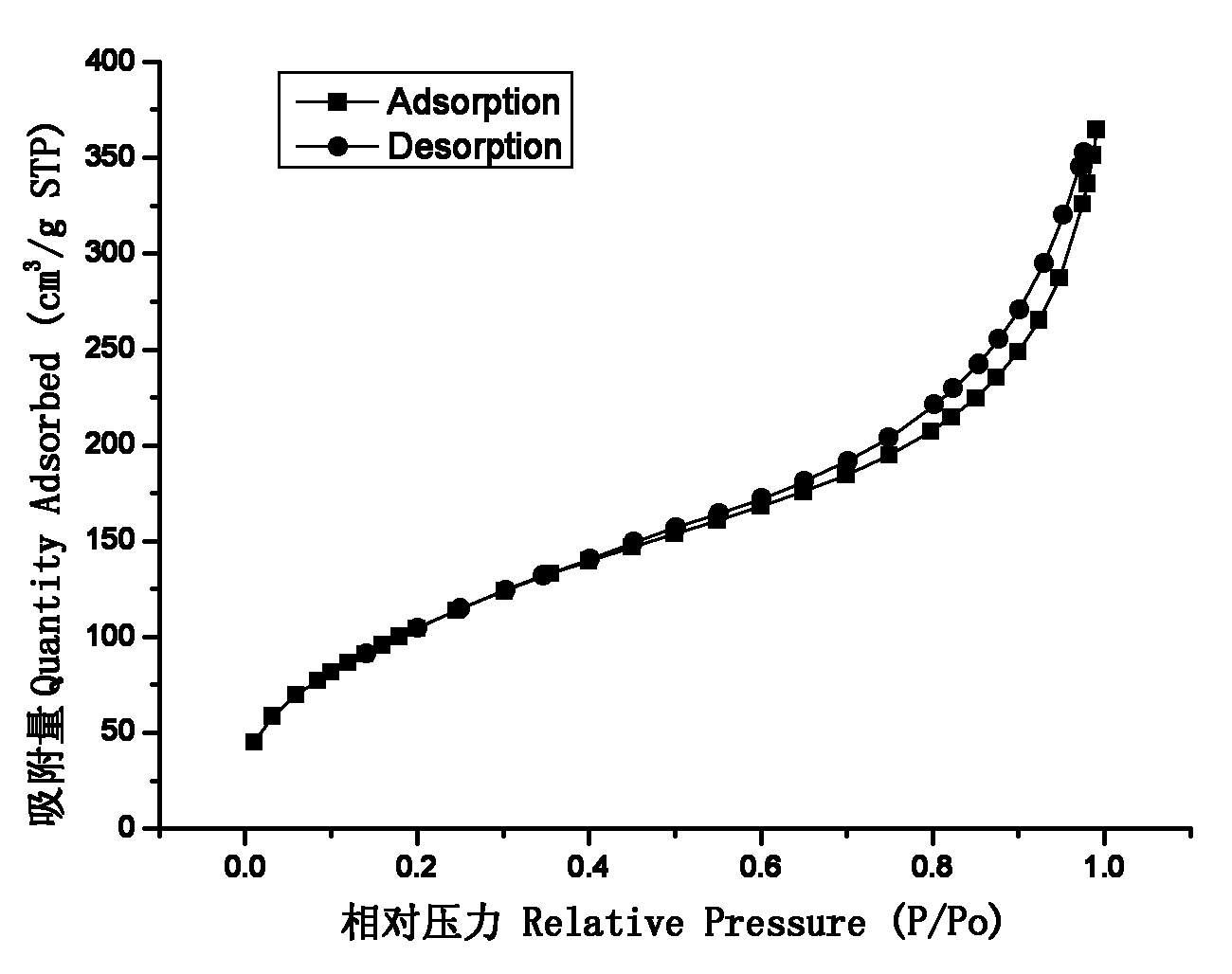

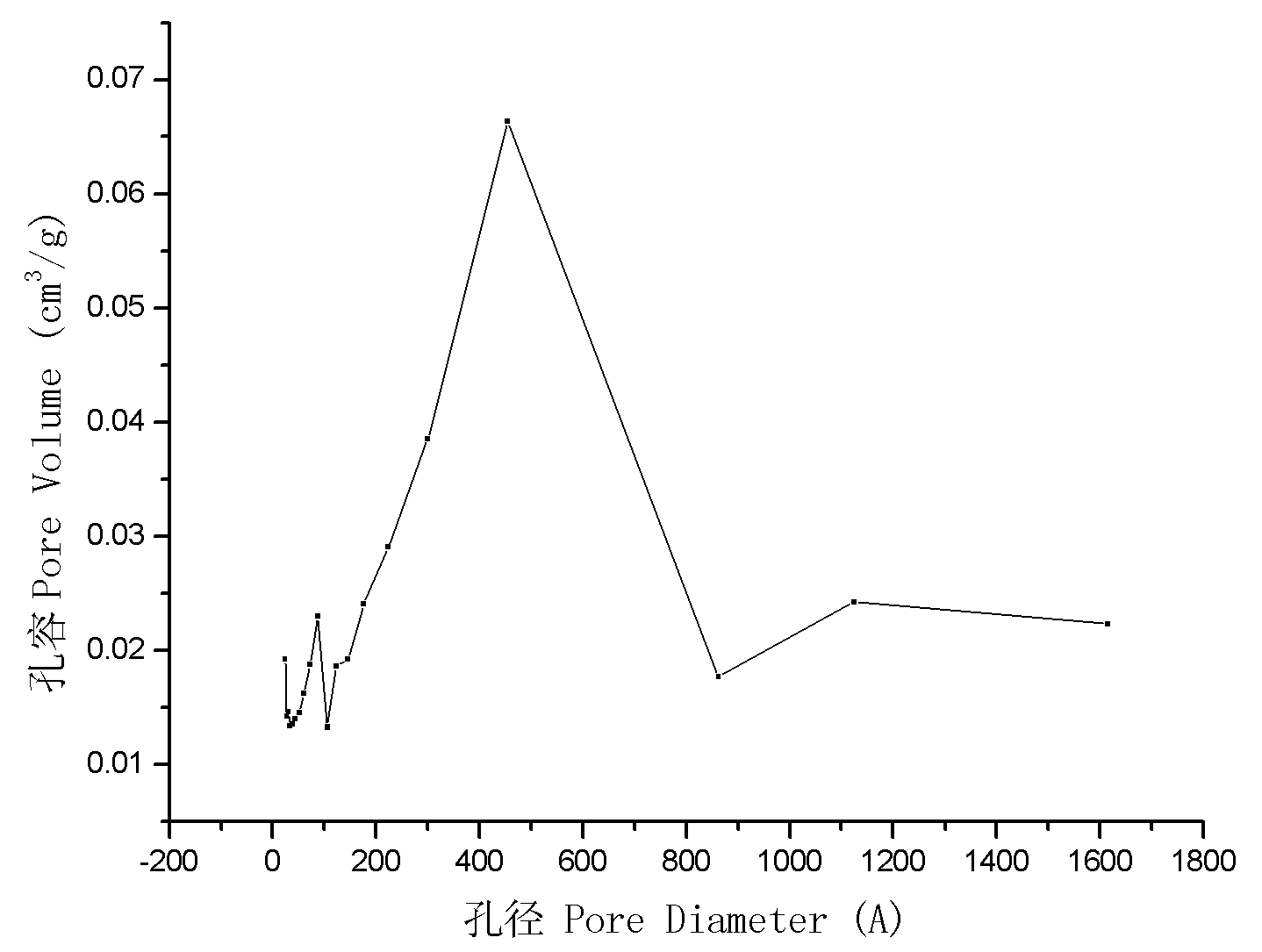

[0027] The mesoporous support was prepared according to Example 26. Put 5 g of mesoporous carrier, 25 mL of silane coupling agent KH-5500, and 45 mL of toluene into the reactor, reflux for 12 hours, then suction filter, wash with ethanol, and dry at 105°C. The resulting product was reacted with 5 g of 1,3-propane sultone at 80°C for 3 hours, then suction filtered, washed with ethyl acetate, and dried at 105°C. React with 1g of sulfuric acid and 20mL of water at 80°C for 3h, rotary evaporate, and dry at 105°C to obtain the finished catalyst.

Embodiment 2

[0029] Put 5g of mesoporous carrier, 15mL of silane coupling agent KH-5500, and 30mL of toluene into the reactor, reflux for 10 hours, then suction filter, wash with ethanol, and dry at 105°C. The resulting product was reacted with 5 g of 1,3-propane sultone at 80°C for 3 hours, then suction filtered, washed with ethyl acetate, and dried at 105°C. React with 1g of sulfuric acid and 20mL of water at 80°C for 3h, rotary evaporate, and dry at 105°C to obtain the finished catalyst.

Embodiment 3

[0031] Put 5g of mesoporous carrier, 10mL of silane coupling agent KH-550, and 15mL of toluene into the reactor, reflux for 8 hours, then suction filter, wash with ethanol, and dry at 105°C. The resulting product was reacted with 5 g of 1,3-propane sultone at 80°C for 3 hours, then suction filtered, washed with ethyl acetate, and dried at 105°C. React with 1g of sulfuric acid and 20mL of water at 80°C for 3h, rotary evaporate, and dry at 105°C to obtain the finished catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com