Aluminium electrolysis bus system resistance to ground detection device and detection method thereof

A technology of earth resistance and busbar system, applied in measuring devices, measuring resistance/reactance/impedance, instruments, etc., can solve problems such as inability to achieve correct detection and monitoring, distributed capacitance, conductive busbar size, insulation point system, complex structure, series connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

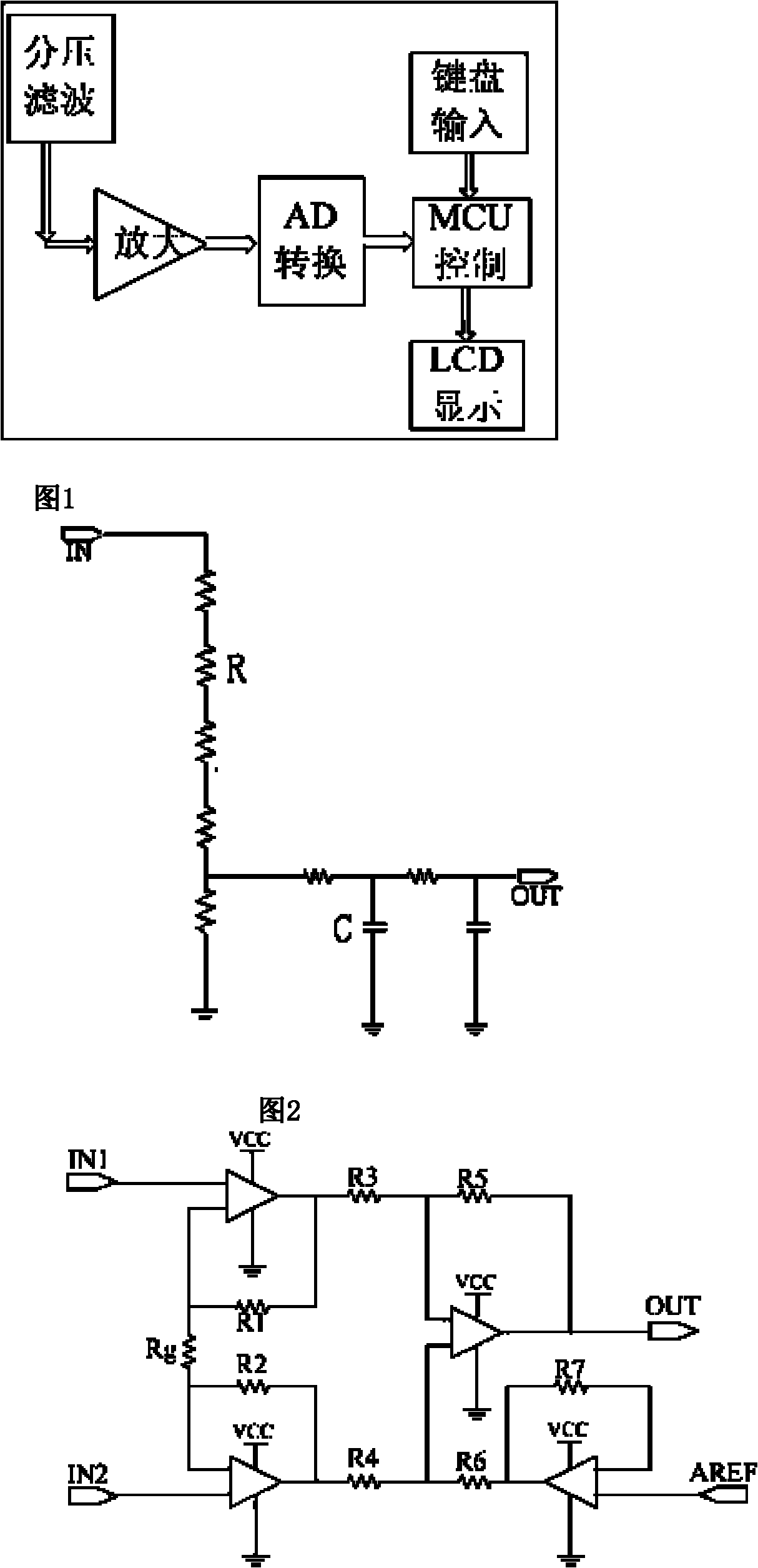

[0023] Embodiments of the present invention: as shown in Figure 1, the present invention is made up of keyboard input device, voltage divider filter, amplifier, MCU controller, LED display, is to be electrically connected between its various parts.

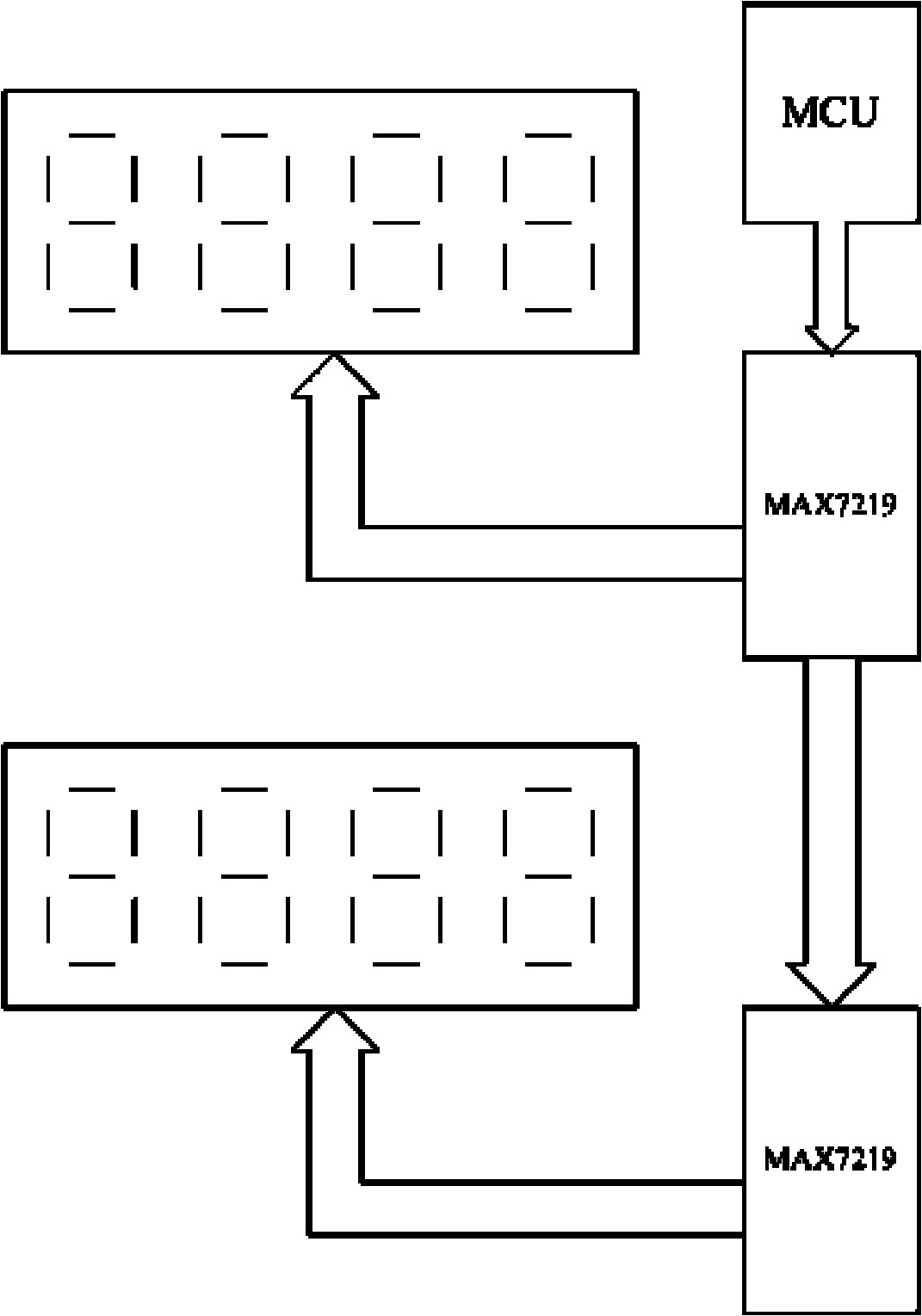

[0024] As shown in Figure 2, the circuit of the voltage divider filter of the aluminum electrolytic bus system ground resistance detector device is formed by connecting high-power precision resistors and capacitors. The circuit of the voltage divider filter is to reduce the voltage on the electrolytic tank to the collection range of AD through the high-power precision resistor R, and then filter through the RC circuit, that is, the resistor-capacitor circuit. The circuit generally uses 5 to 6 high-power precision resistors and 4 to 5 filter capacitors.

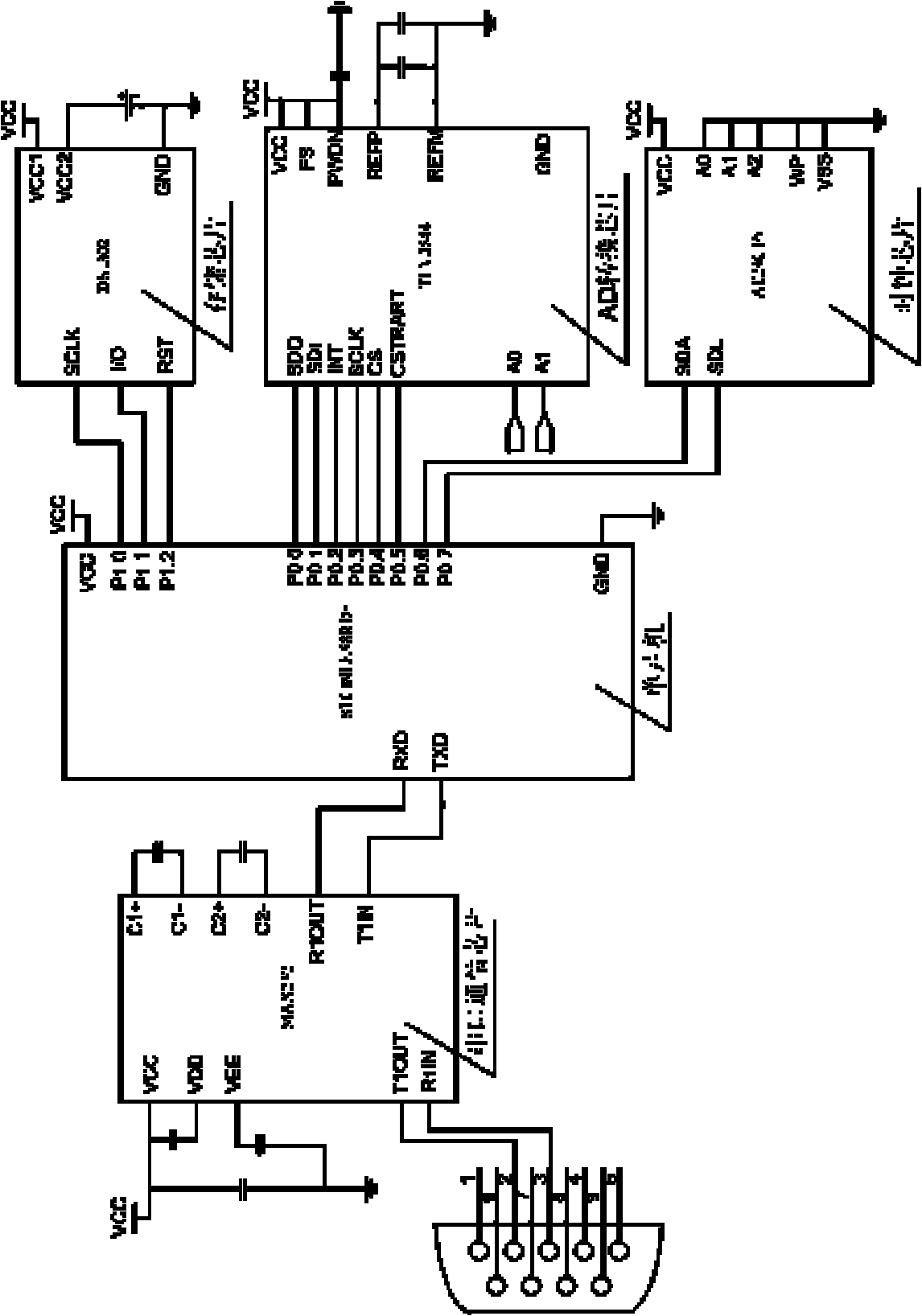

[0025] like image 3 As shown, the circuit of the amplifier of the aluminum electrolytic bus system ground resistance detector device is composed of 4 integrated operational ampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com