Method for preparing ethylbenzene by alkylating pure ethylene or dry gas and benzene

A technology for benzene alkylation and pure ethylene, applied in chemical instruments and methods, organic chemistry, chemical recovery, etc., can solve problems such as short regeneration cycle and service life, poor catalyst stability, and low purity of ethylbenzene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

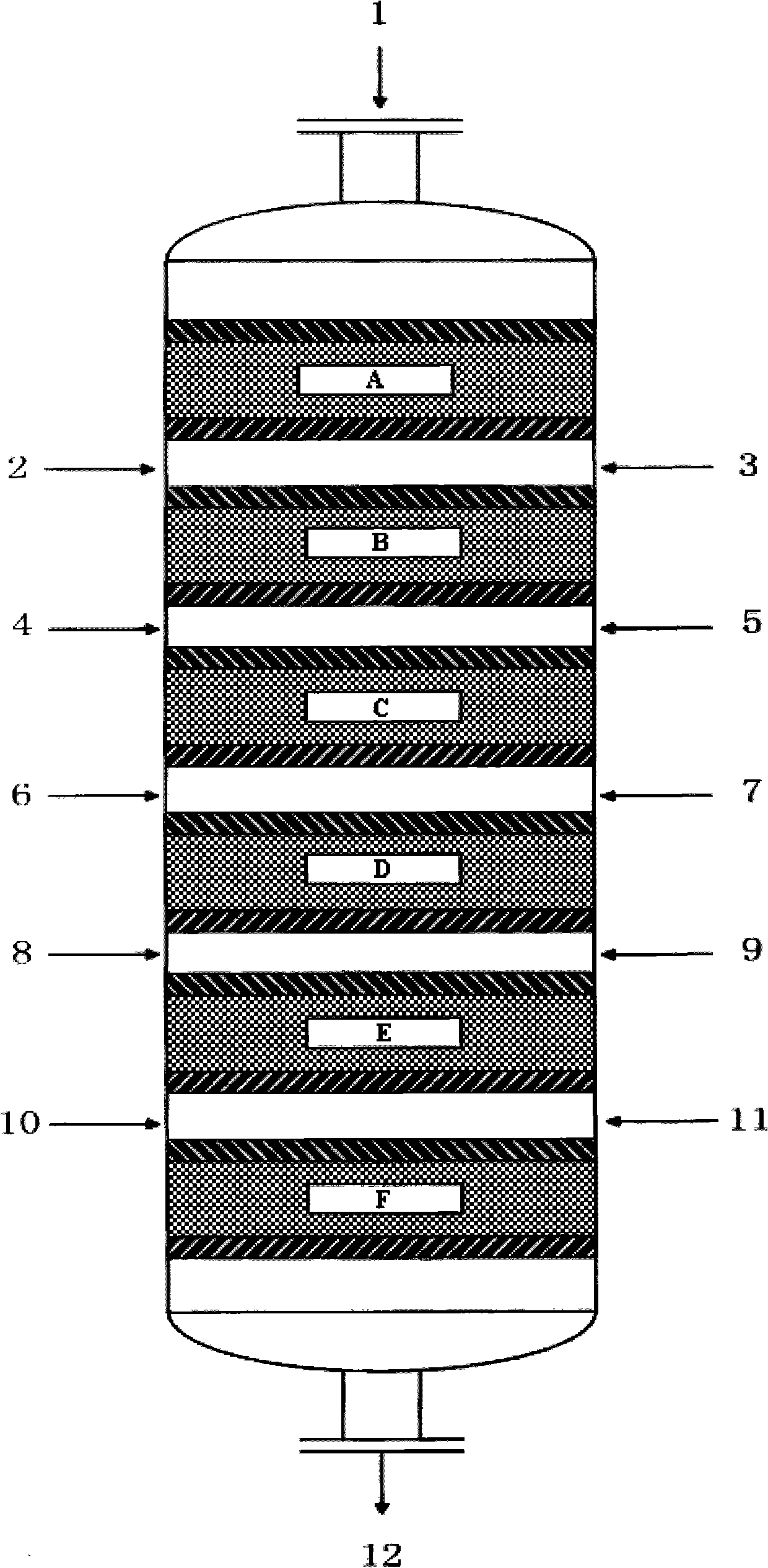

Method used

Image

Examples

Embodiment 1

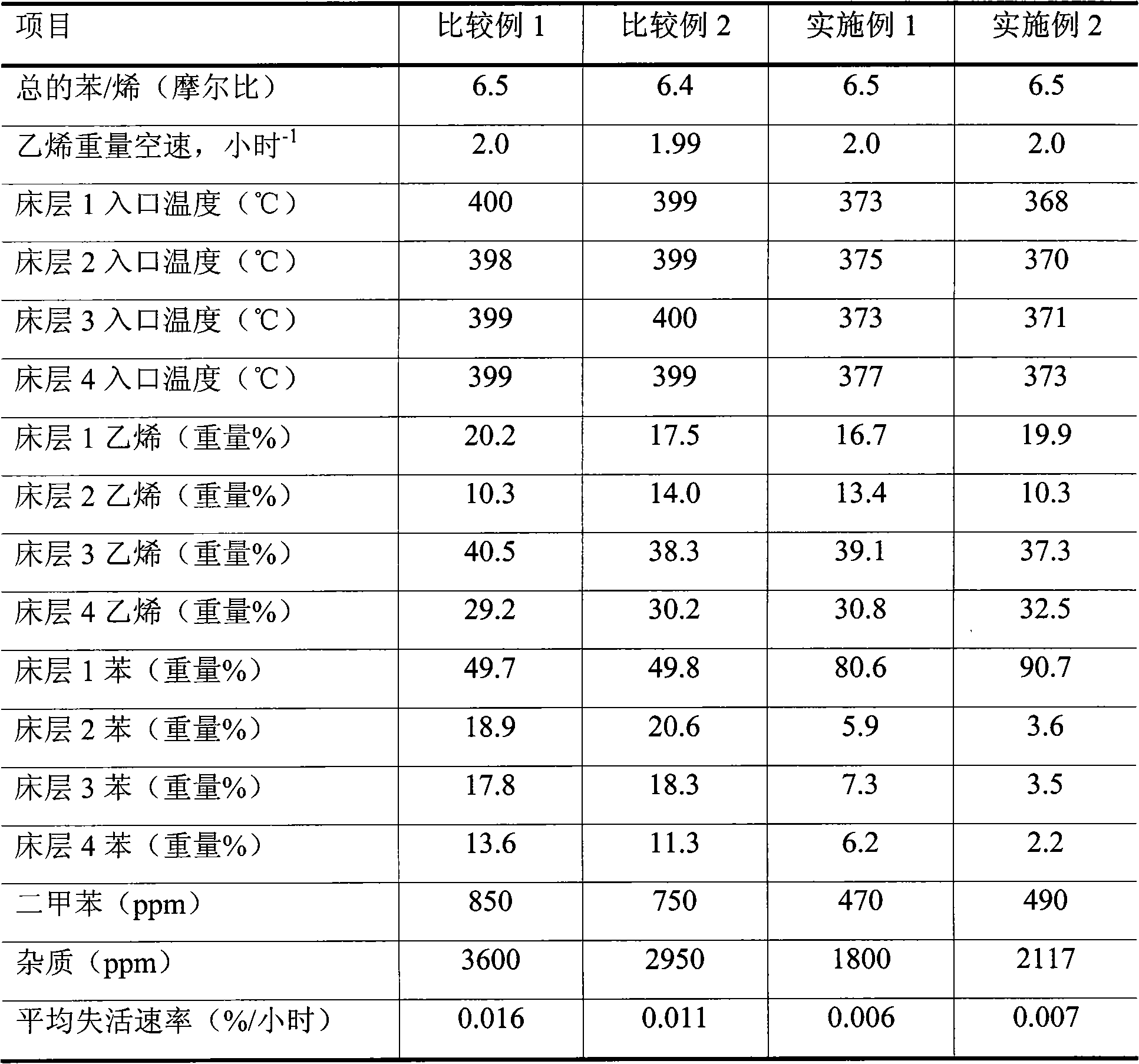

[0020] 4 grams of Catalyst A are packed in the upper 2 layers of the four-bed fixed-bed reactor, and 4 grams of Catalyst B are packed in the lower 2 layers of the four-bed fixed-bed reactor. Using pure ethylene as raw material, the total benzene / ethylene molar ratio is 6.5 / 1, and the ethylene weight space velocity is 2.0 hours -1, 80.6% of benzene enters from the top of the reactor. Reaction result: ethylene conversion rate is 99.92%, ethyl selectivity is 99.83%. The inlet temperature of each catalyst bed is lower than when the same active catalyst is used, and the xylene and impurity content and the stability of the catalyst are significantly better than the level when the same active catalyst is used. The detailed results are shown in Table 1. .

Embodiment 2

[0022] 4 grams of Catalyst A are packed in the upper 2 layers of the four-bed fixed-bed reactor, and 4 grams of Catalyst B are packed in the lower 2 layers of the four-bed fixed-bed reactor. Using pure ethylene as raw material, the total benzene / ethylene molar ratio is 6.5 / 1, and the ethylene weight space velocity is 2.0 hours -1 , 90.7% of benzene enters from the top of the reactor. Reaction result: ethylene conversion rate is 99.93%, and ethyl selectivity is 99.72%, and the xylene and impurity content of generation and the stability of catalyst are also significantly better than the level when using the same active catalyst. The detailed results are shown in Table 1.

[0023] Table 1 Alkylation reaction of pure ethylene in four-bed reactor

[0024]

Embodiment 3

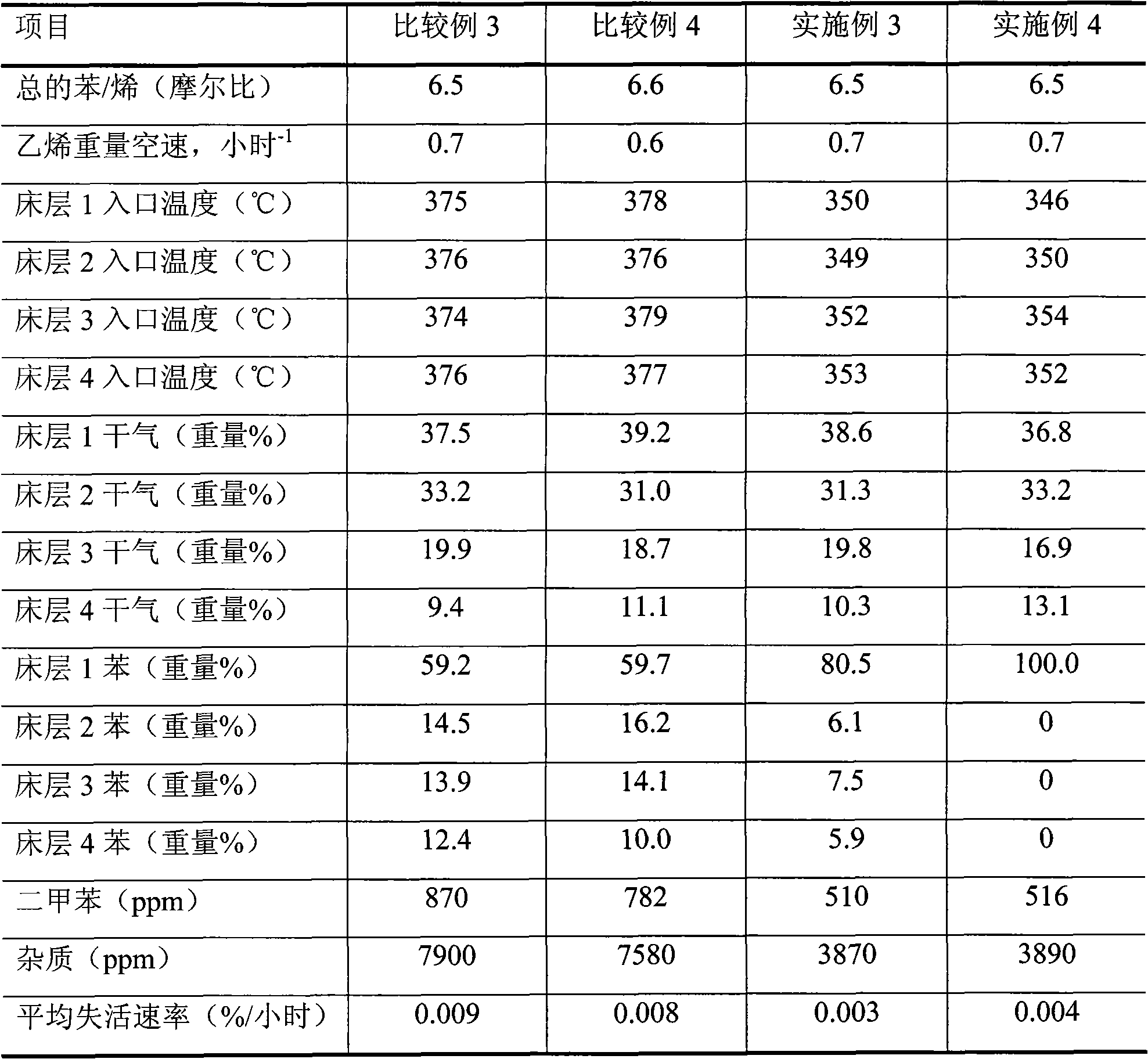

[0030] 4 grams of Catalyst C are packed in the upper 2 layers of the four-bed fixed-bed reactor, and 4 grams of Catalyst D are packed in the lower 2 layers of the four-bed fixed-bed reactor. The dry gas used contains free water 170ppm, H 2 S7500mg / m 3 , CO 2 3.0 (body)%, C 3 = and C 4 = 0.7 (volume)% and ethylene 14.8% components, directly react with benzene without pre-purification, the total benzene / ethylene molar ratio is 6.5 / 1, and the ethylene weight space velocity is 0.7 hours -1 , 80.5% of benzene enters from the top of the reactor. Reaction result: ethylene conversion rate is 99.82%, ethyl selectivity is 99.57%. The inlet temperature of each catalyst bed is lower than that of a single catalyst, and the content of xylene and impurities and the stability of the catalyst are significantly better than that of a single catalyst. The detailed results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com