Insulating back plate for solar photovoltaic component

A solar photovoltaic and component technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems that affect the service life of solar photovoltaic components, failure of insulating backplane protection performance, and accelerated decomposition of polyvinylidene fluoride. Low cost, meet the requirements of industrial scale-up production, and ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

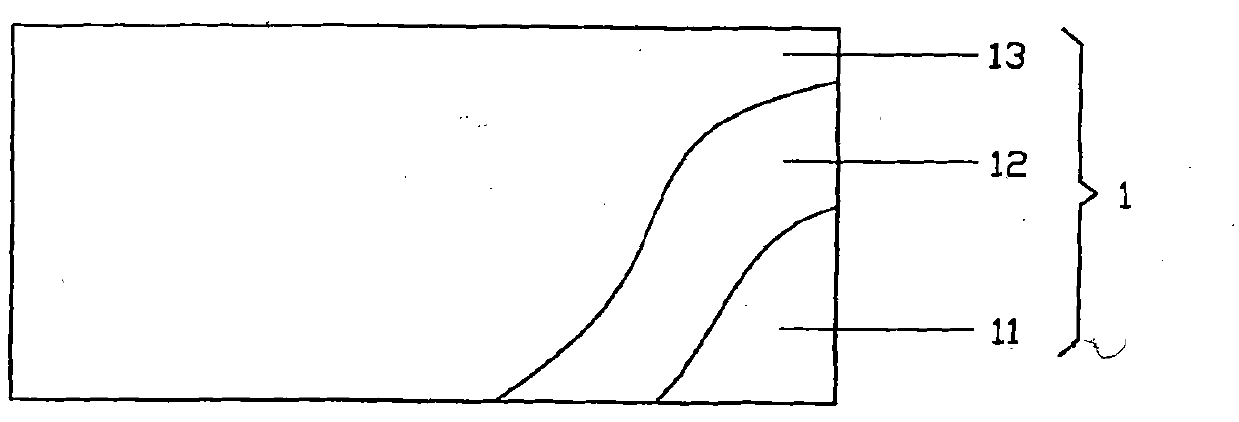

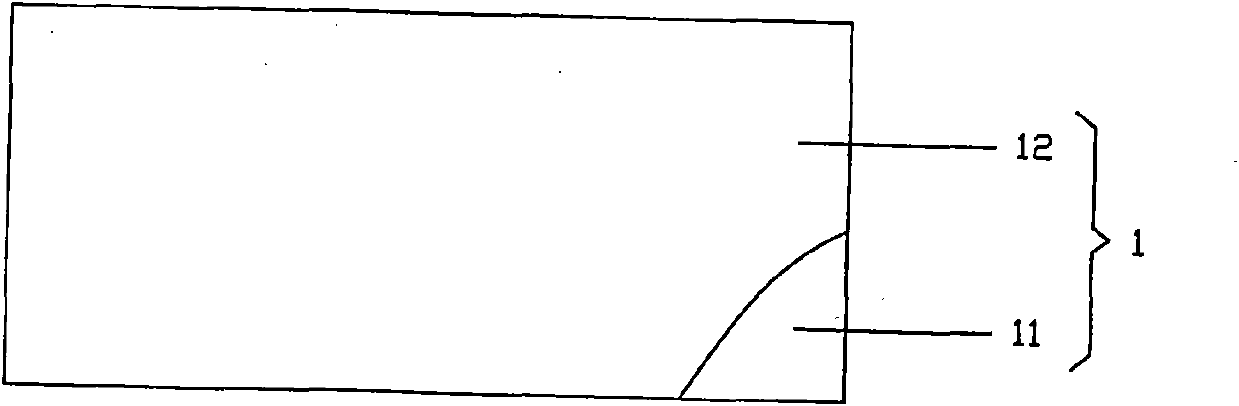

[0024] please see figure 1 , the given insulating backsheet for solar photovoltaic modules includes a weather-resistant layer 1, a thermal adhesive layer 5, and an electrical insulating layer 3 bonded between the weather-resistant layer 1 and the thermal adhesive layer 5, wherein: the electrical insulating layer 3 faces the weather-resistant layer The surface of one side of 1 is combined with the weather-resistant layer 1 through the first adhesive layer 2 (adhesive bonding), and the surface of the side of the electrical insulation layer 3 facing the thermal adhesive layer 5 is connected with the second adhesive layer 4 through the second adhesive layer 4. The thermal adhesive layers 5 are bonded (adhesively bonded). That is to say, the electrical insulating layer 3 is bonded between the weather-resistant layer 1 and the thermal adhesive layer 5 through the first and second adhesive layers 2 and 4 .

[0025] In this embodiment, the weather-resistant layer 1 has a thickness of...

Embodiment 2

[0028] The thickness of the weather-resistant layer 1 is 50 μm, and the thickness of the electrical insulating layer 3 is changed to 250 μm; 1 part and 1 part, wherein: polybutylmethacrylate is used for acrylic resin, carbon black is used for inorganic material; acrylic adhesive is used for the materials of first and second bonding layers 2 and 4, and acrylic adhesive is used for the materials of electrical insulating layer 3 The material used is polyethylene 2,6-naphthalate, the material of the thermal adhesive layer 5 is changed to polypropylene, and the thickness is changed to 120 μm. All the other are the same as the description to embodiment 1.

Embodiment 3

[0030] Change the thickness of the weather-resistant layer 1 to 30 μm, change the thickness of the electrical insulating layer 3 to 180 μm, and use polyamide as the material of the electrical insulating layer 3; The parts by weight were respectively changed to 65 parts, 55 parts and 28 parts, wherein: polybutylmethacrylate was used for the acrylic resin, ethylene-vinyl acetate was used for the thermal adhesive layer 5, and the thickness was 198 μm. All the other are the same as the description to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com