Tyre forming apparatus

A tire forming and tire technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of reduced production efficiency, time and labor consumption, etc., and achieve the effect of improving tire quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

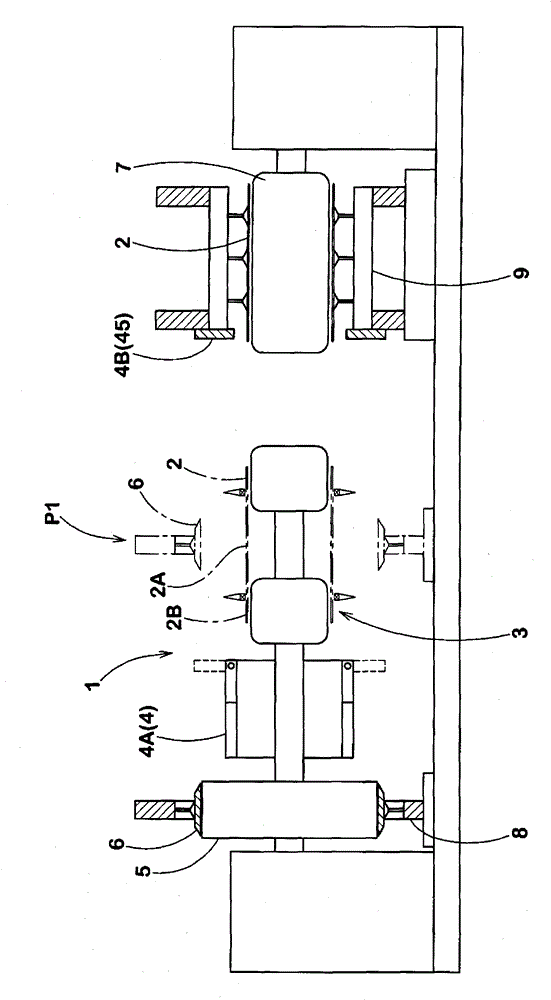

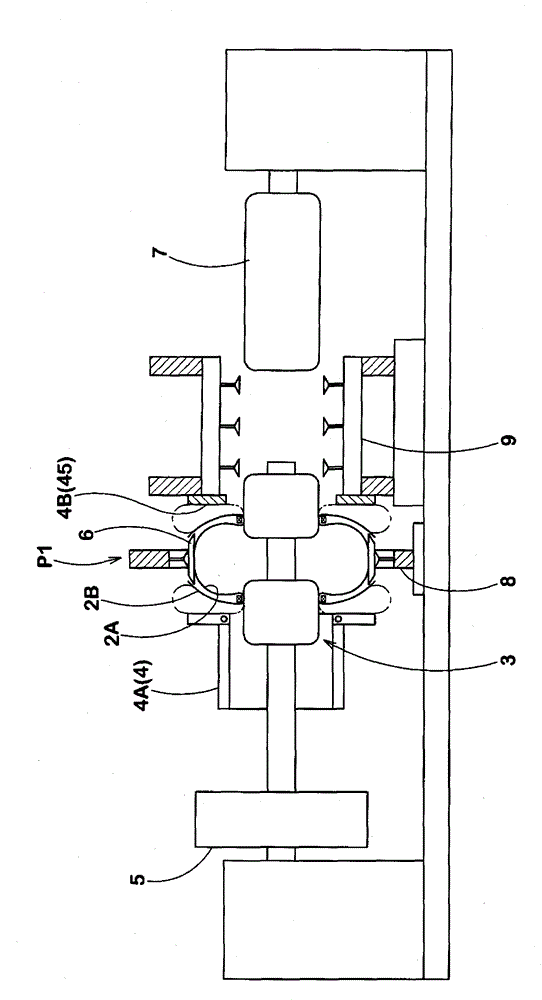

[0038] Next, embodiments of the present invention will be described in detail. figure 1 , figure 2 It is a side view schematically showing an example of a tire building line using the tire building apparatus of the present invention.

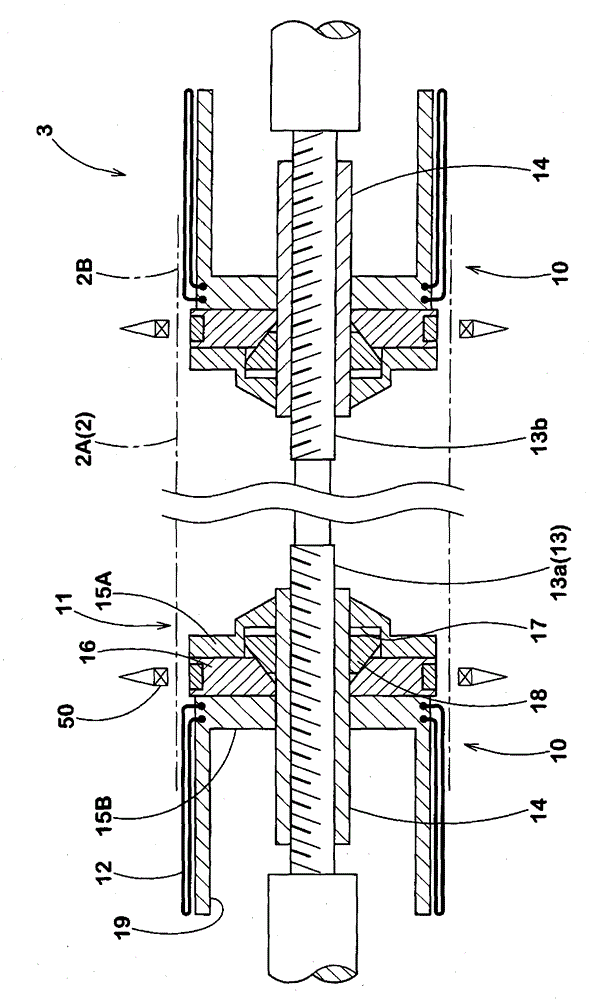

[0039] exist figure 1 , figure 2 Among them, the tire building apparatus 1 of the present embodiment includes: a shaping drum 3 that holds a cylindrical tire casing 2 including a carcass, expands the casing main body portion 2A into a ring shape, and simultaneously expands the casing protruding portion 2B is rolled up; the crimping unit 4 crimps and joins the above-mentioned rolled up case extension portion 2B to the ring-shaped case main body portion 2A.

[0040] here, figure 1 , figure 2 The middle symbol 5 is a so-called belt drum, for example, by sequentially winding tread constituent members including a belt ply, a tread reinforcing cord such as a belt ply, and a tread rubber around the belt drum 5 . On the outer peripheral surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com