Preparation method of haematococcus pluvialis extracts

A technology of Haematococcus pluvialis and its extract, which is applied in the field of preparation of Haematococcus pluvialls extract, can solve the problems of large consumption of chemical reagents, sensitivity and instability, and solvent residue, and achieve low cost and reliable quality. control, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation process of Haematococcus extract

[0032] This example optimizes the preparation process for the preparation of Haematococcus pluvialis extract by supercritical fluid extraction, specifically including the following steps:

[0033] 1) Broken wall of Haematococcus pluvialis

[0034] A. Wall breaking equipment

[0035] A high-pressure homogenizer is used for wall-breaking treatment.

[0036] B. According to the processing capacity and processing effect of the existing high-pressure homogenizer, the maximum processing capacity of algae mud at one time is 400-500kg (equivalent to 3000m 2 The total amount of algae sludge harvested by the culture system at one time).

[0037] C. The control parameters are shown in Table 1.

[0038] Table 1 Process control parameters of Haematococcus red spore wall breaking

[0039]

[0040] D. In addition to meeting the requirements of the above control parameters during the process of breaking the wall of Haem...

preparation example

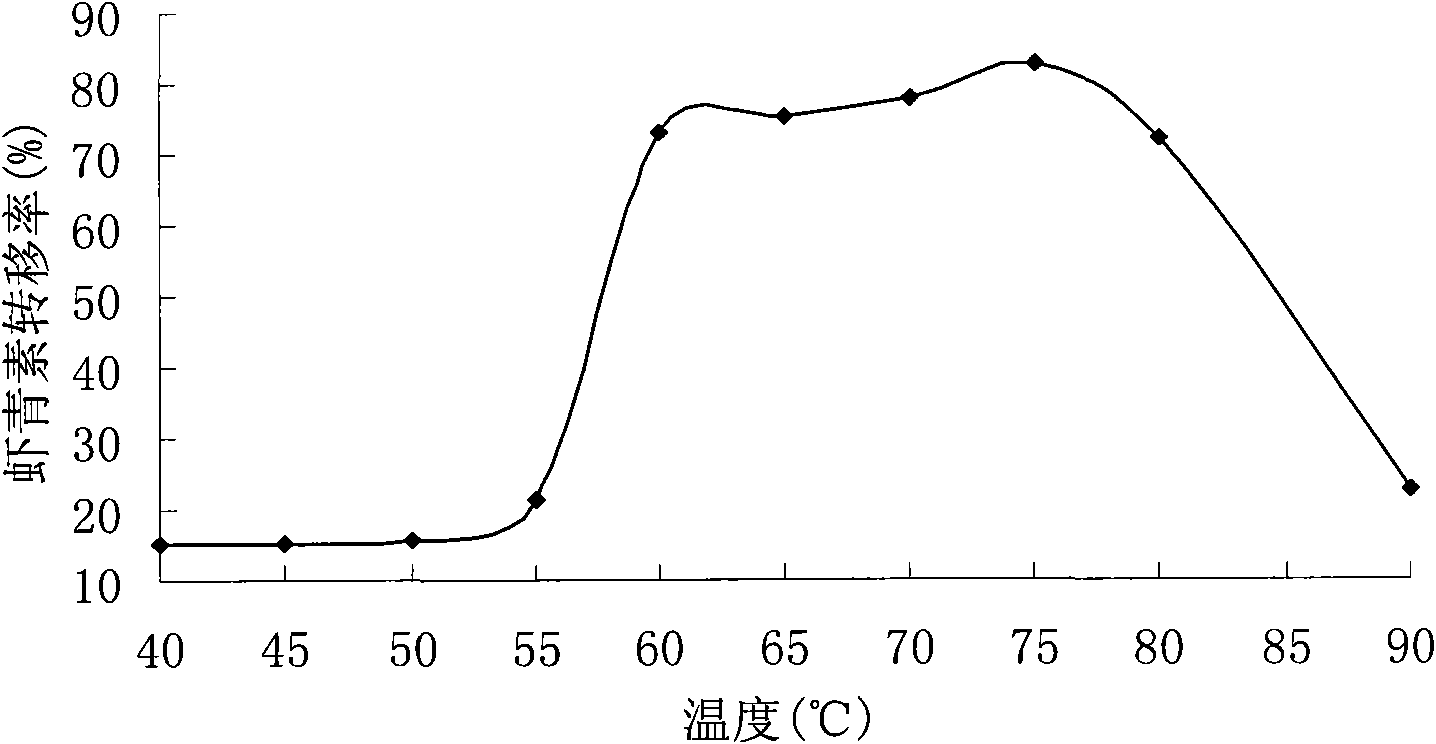

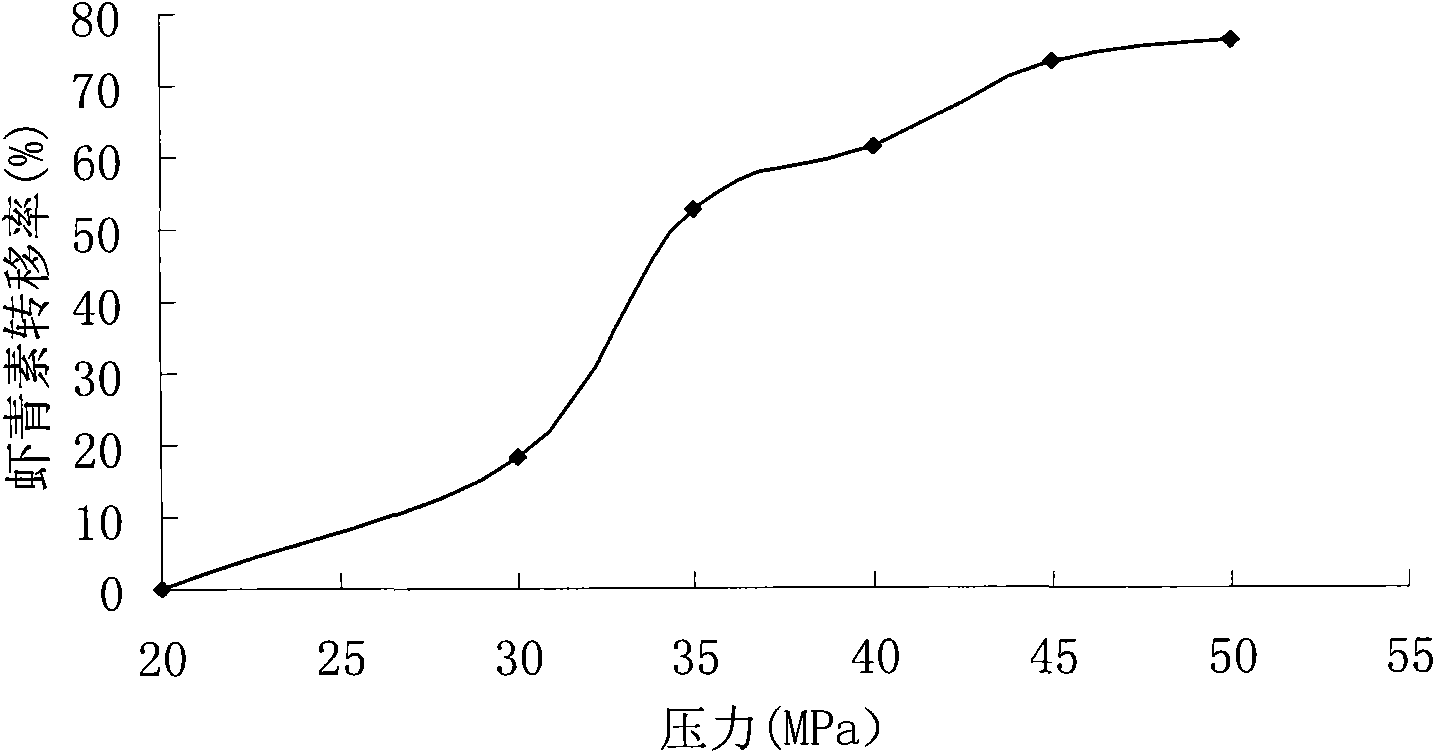

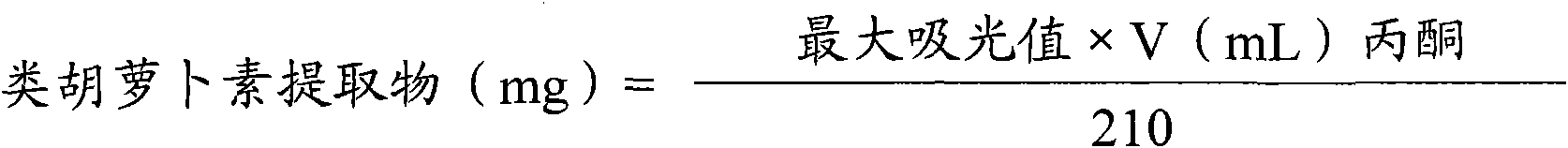

[0058] Pack the broken Haematococcus pluvialis powder 500g into the extraction kettle of supercritical extraction equipment (HA121-50-02 type extraction device, Jiangsu Huaan Scientific Research Instrument Co., Ltd.), set the temperature and pressure of the extraction kettle and the separation kettle, and open equipment, open CO 2 The gas tank is used to heat and pressurize the extraction kettle at the same time. When the temperature reaches the extraction temperature of 70°C and the pressure reaches the extraction pressure of 45MPa, heat preservation and pressure are maintained while controlling the CO 2 Flow rate (15-25L / h), after extracting for 2-4 hours, receive a total of 125g of Haematococcus pluvialis extract from the outlet valve of the separation tank (50°C, 9MPa). It is determined that the mass percent content of astaxanthin in the Haematococcus pluvialis extract is 9.66%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com