Splashing-preventing hood for frying machine

A technology of splash-proof cover and fryer, applied in the direction of oil/fat roasting, etc., can solve the problems of reduced environmental sanitation level, redness and pain, corrosion of equipment and objects, etc., and achieve the effect of eliminating the original pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

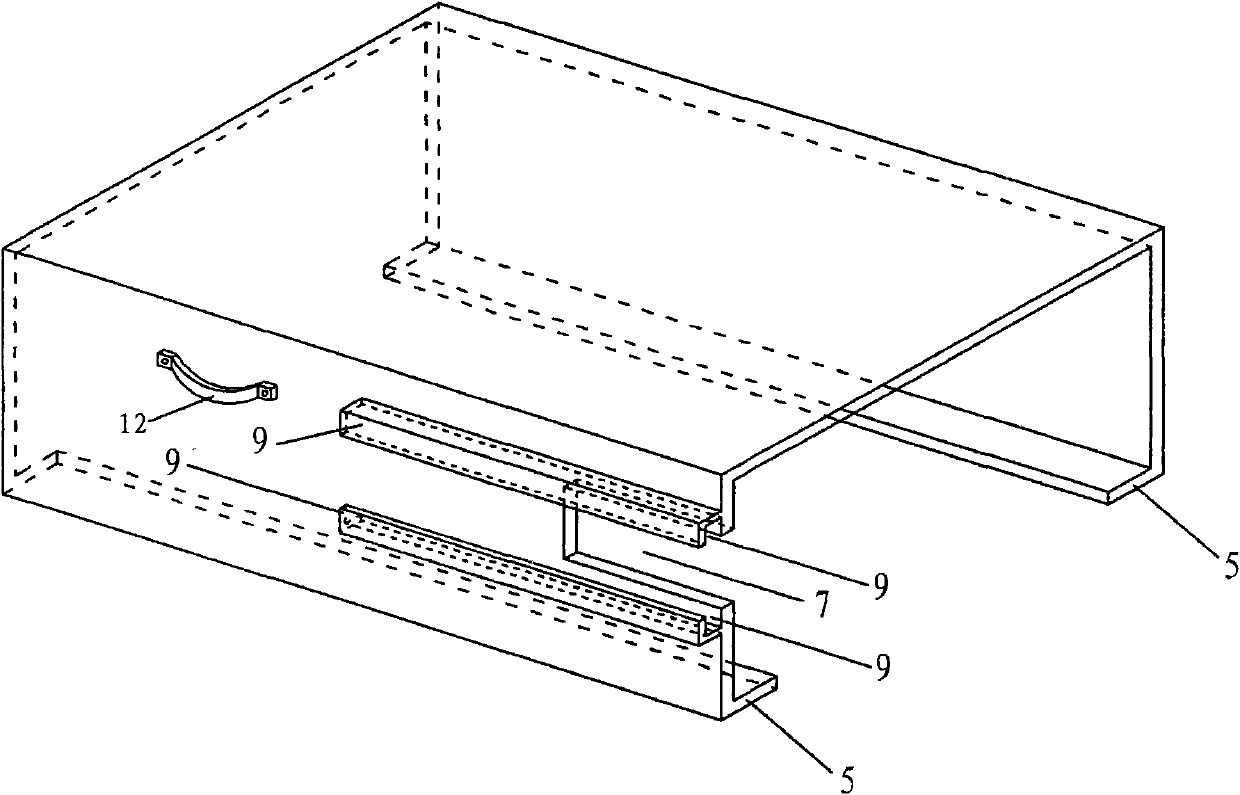

[0025] Example 1, see Figure 5 and Figure 7 . The main part of the splash guard at the height above the bottom edge of the window 7 is made of a transparent high-temperature resistant and pollution-free material (shown in the thin line in the figure), and the downward continuous part not higher than the bottom edge of the window 7 is a stainless steel plate (thick in the figure). (shown by the line) rolling, the transparent material part and the stainless steel plate part are fixedly connected through several riveting points 10.

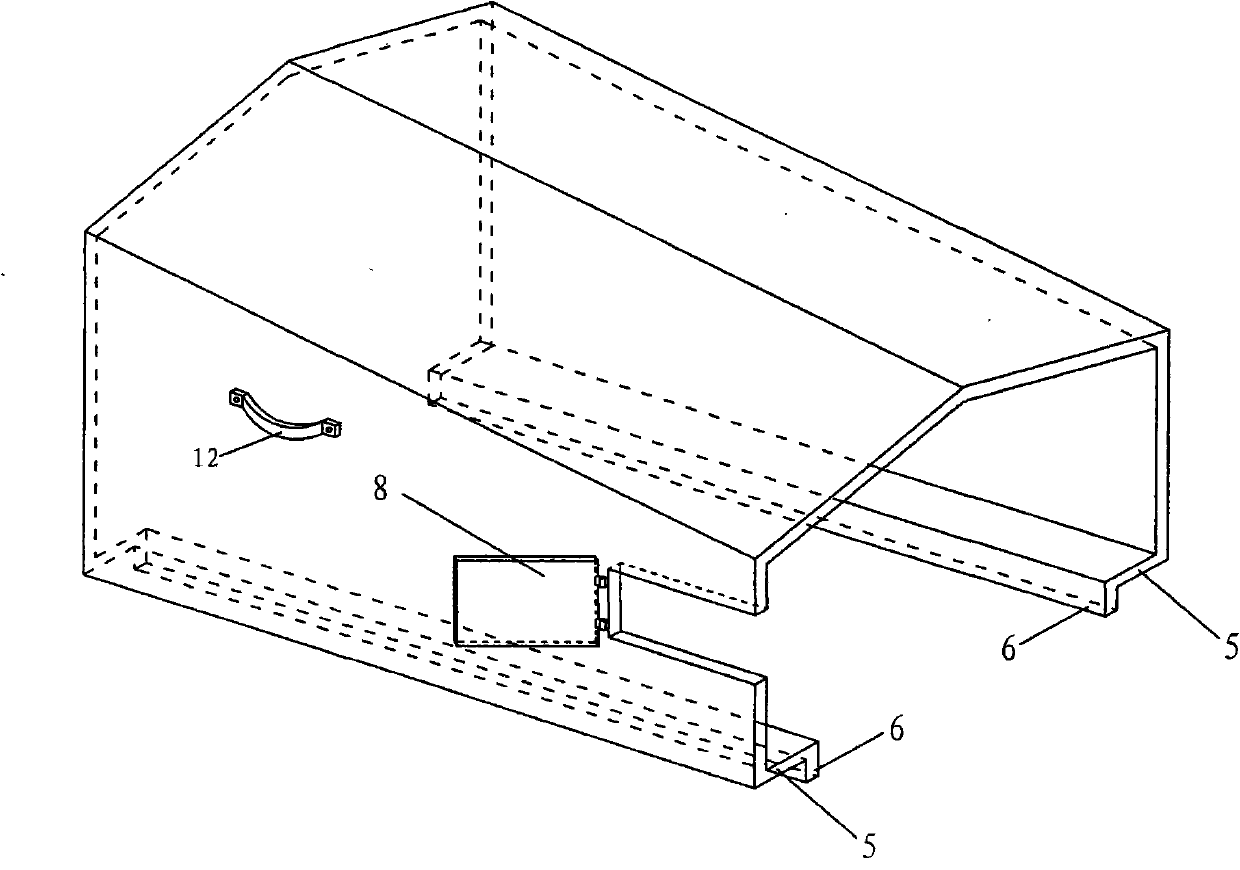

[0026] The top of the splash guard is a space folding surface with a lower end and a higher end. The higher end is suitable for attaching to the oil fume collection cover 2 of the fryer. The current phenomenon of lampblack falling in the workshop.

[0027] The side window 7 is close to the filter screen port at the end of the frying tank 1, and tools can be used to clean up the debris blocking the filter screen port from the window 7 without ful...

Embodiment 2

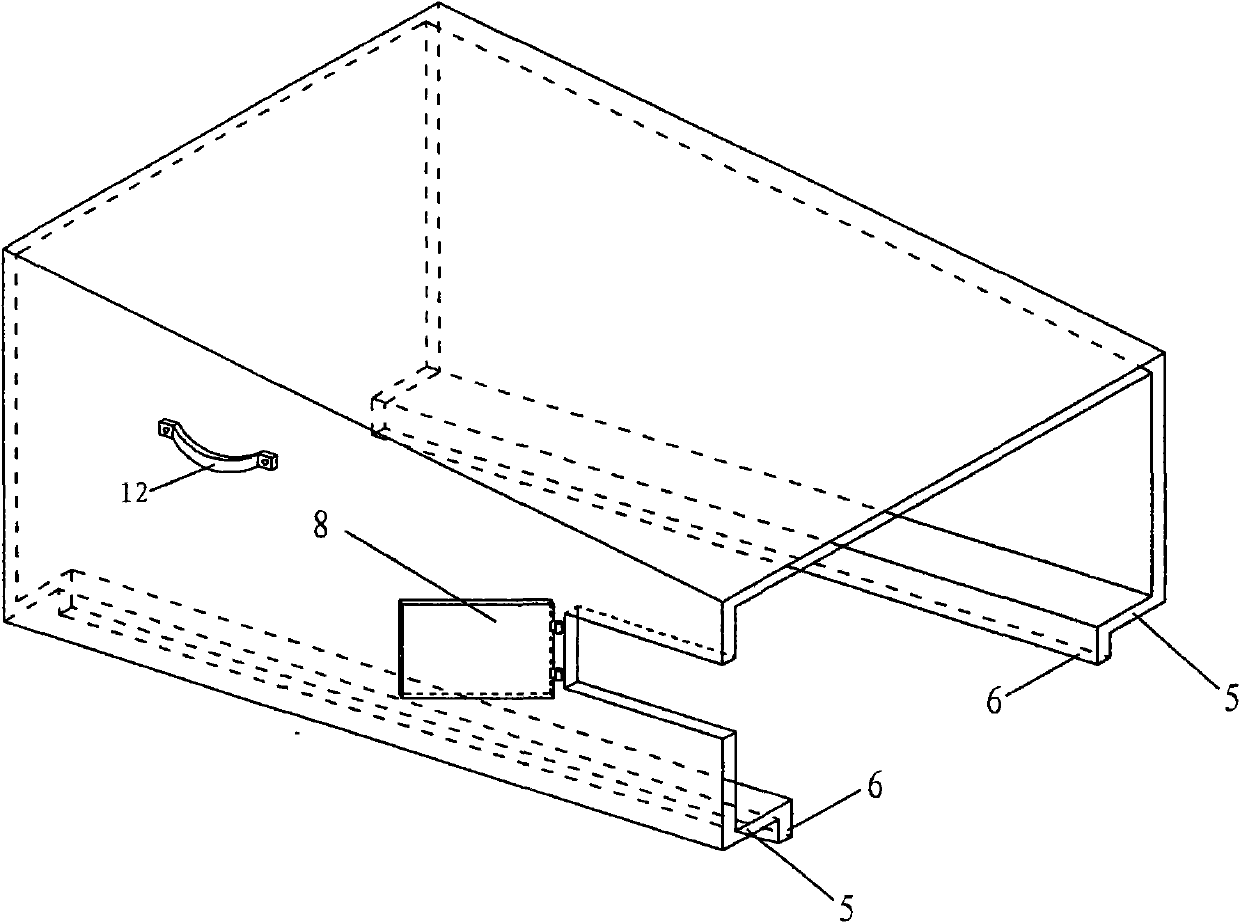

[0031] Example 2, see Figure 6 , The top of the splash guard is arc-shaped, which is beneficial for the splashed oil droplets to flow into the oil discharge tank along the inner wall. The rest are the same as embodiment 1.

Embodiment 3

[0032] Example 3, see Figure 4 , The splash guard is made of transparent high temperature resistant material as a whole. If necessary, add a thin layer of heat insulating material on the side of the flat section 5 and the vertical section 6 that is intended to contact the side 4 of the frying tank 1, so as to block the high temperature of the boiling oil from passing through the stainless steel side 4 to the flat section 5 and the vertical section. Section 6 Conduction. The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com