Apparatus for manufacturing chip-type ceramic electronic component and method for manufacturing chip-type ceramic electronic component

A technology for electronic components and manufacturing devices, which is applied to the manufacturing device of chip-type ceramic electronic components and the manufacturing field of chip-type ceramic electronic components, can solve the problems of easy generation of chips, cracks, etc., and achieves prevention of adhesion, improved productivity, The effect of high connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] Embodiments of the present invention are shown below, and their characteristic features will be described in more detail.

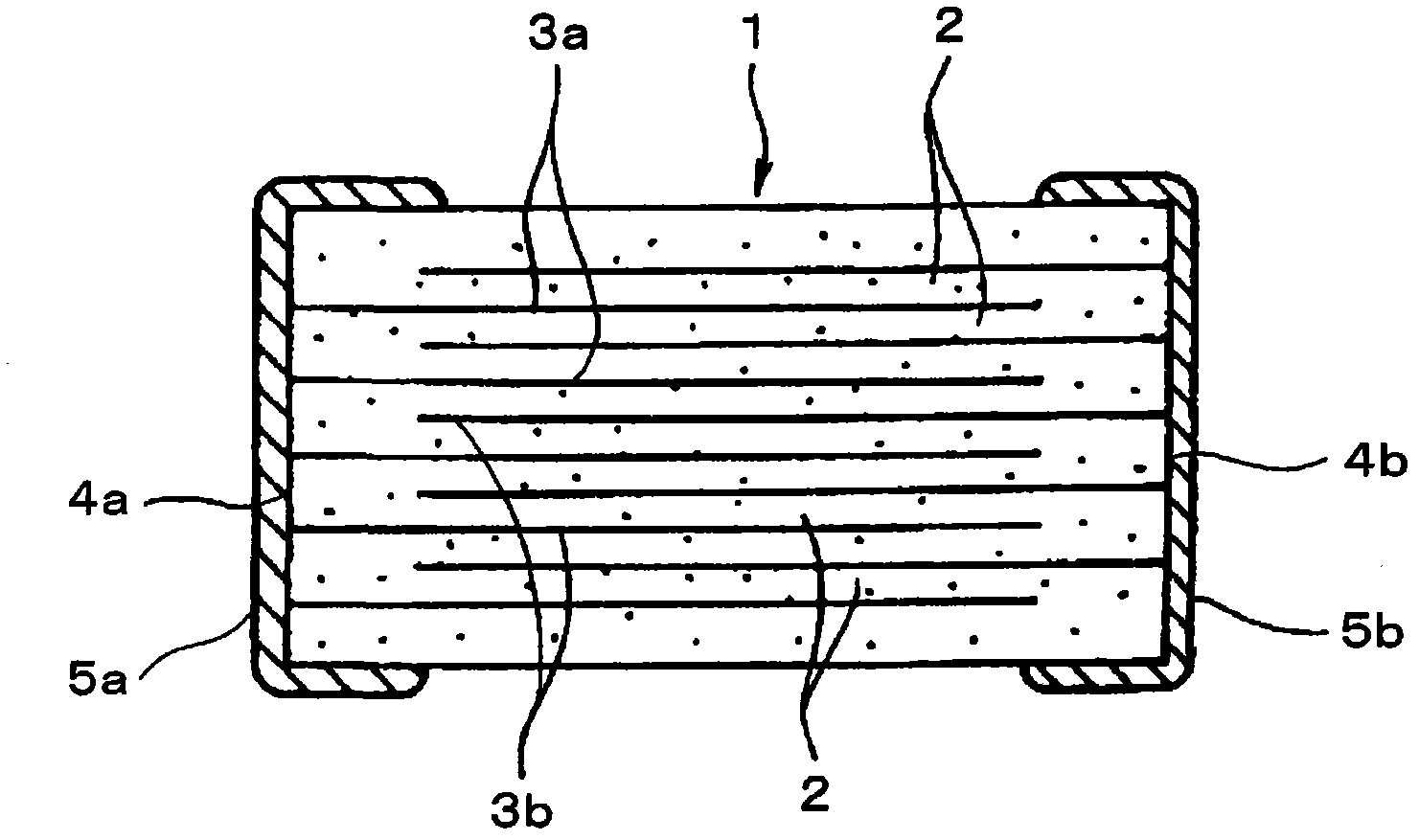

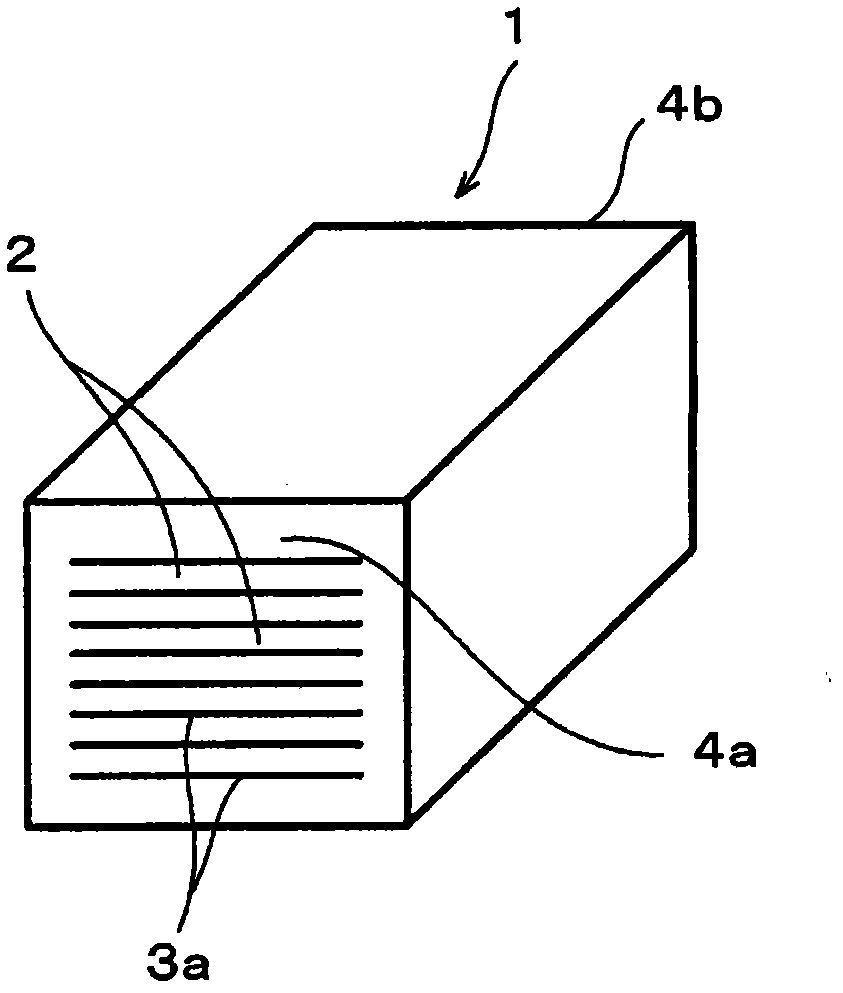

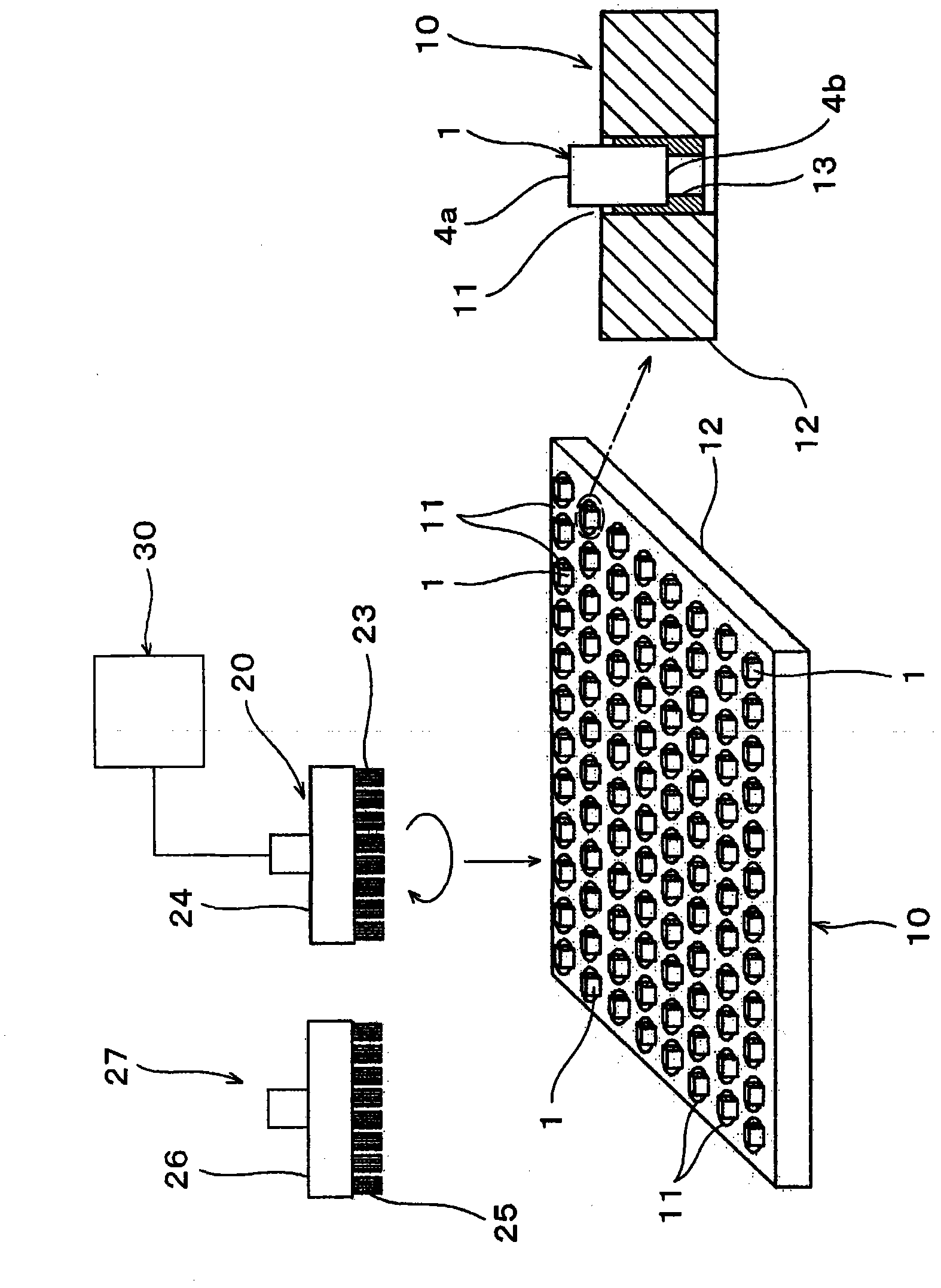

[0092] In this embodiment, description will be made taking as an example the case of manufacturing a laminated ceramic capacitor having the following configuration, for example, as figure 1 As shown, a pair of external electrodes 5a, 5b are arranged on the facing end surfaces 4a, 4b of the ceramic element (chip type element) 1 in a manner to conduct with the internal electrode layers 3a, 3b, wherein the ceramic element (chip type element) A plurality of internal electrode layers 3 a , 3 b are disposed so as to face each other across a ceramic layer (dielectric layer) 2 .

[0093] Furthermore, in this embodiment, when manufacturing the above-mentioned multilayer ceramic capacitor, as figure 1 , figure 2As shown, the following chip-type element (ceramic element) 1 is prepared: the internal electrode layers 3a, 3b and the ceramic layer 2 are alte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com