Radiating module

A technology of heat dissipation module and heat dissipation fin set, which is applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating renovation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

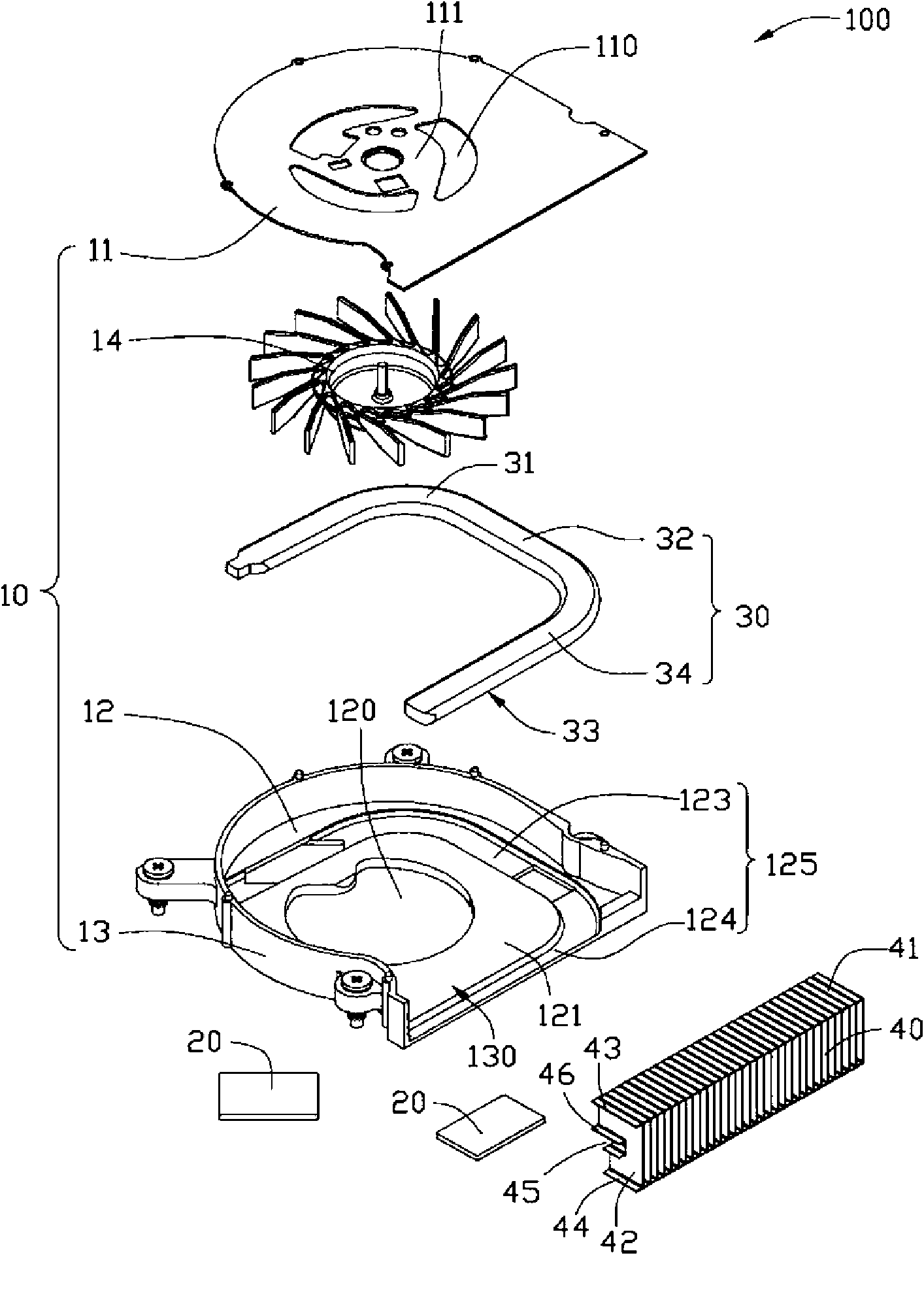

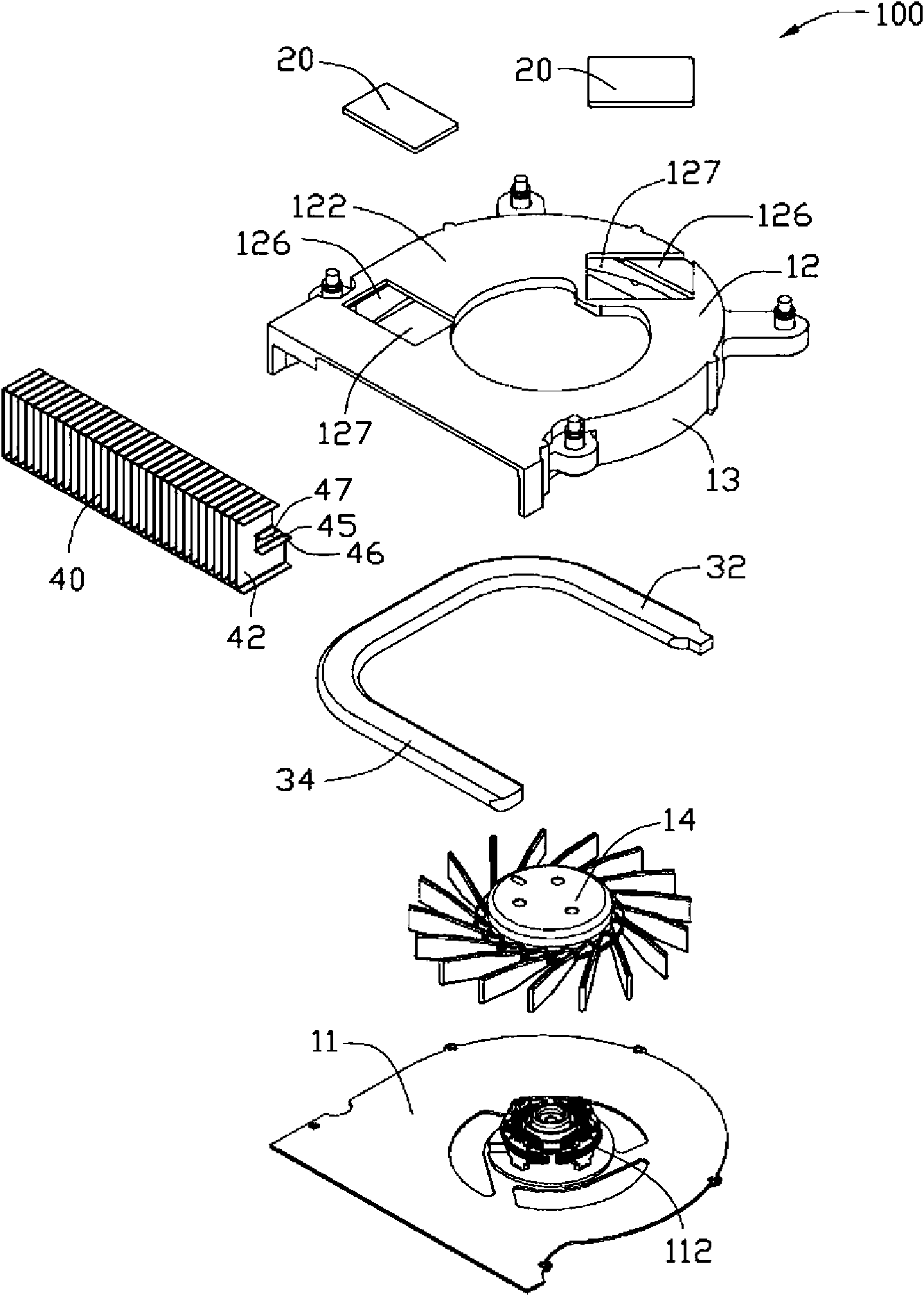

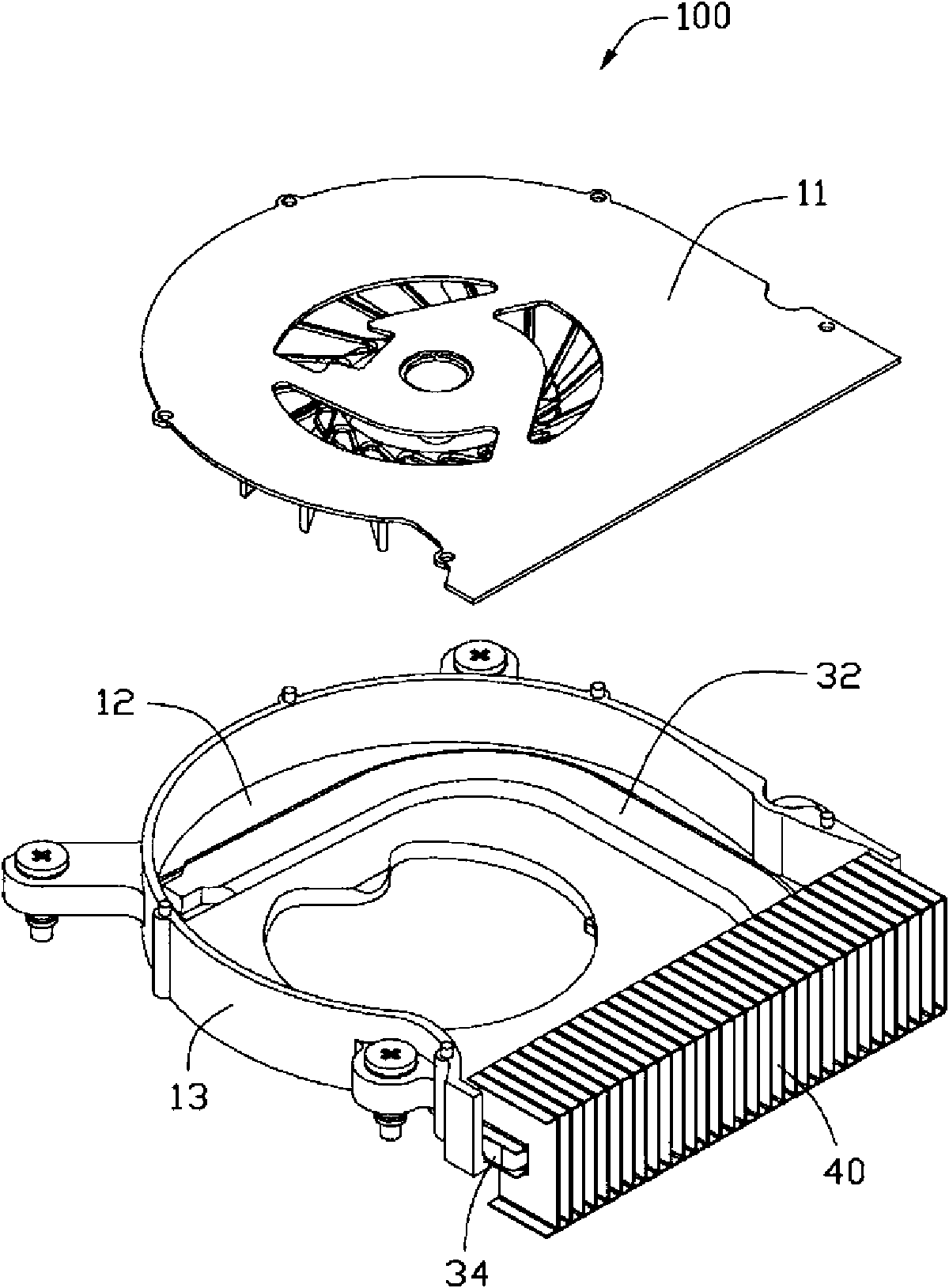

[0012] see figure 1 and figure 2 , the cooling module 100 includes a centrifugal fan 10 , two heat absorbing plates 20 embedded in the bottom of the centrifugal fan 10 , a heat pipe 30 and a cooling fin set 40 housed in the centrifugal fan 10 .

[0013] The two heat-absorbing plates 20 are made of a metal material such as copper with good thermal conductivity, and the two heat-absorbing plates 20 are square and rectangular, and are used to be pasted on the heat-generating electronic components (not shown) to absorb heat generated by the heat-generating electronic components. of heat.

[0014] The heat pipe 30 is roughly U-shaped, and includes an L-shaped evaporating section 32 and a straight-line condensing section 34 . A vacuum-tight chamber is formed inside the heat pipe 30, and a working liquid (not shown) is disposed in the chamber. The heat pipe 30 is flat and includes a top surface 31 and a bottom surface 33 parallel to the top surface 31 .

[0015] The centrifugal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com