Method for magnetically processing fuel

A processing method and fuel magnetization technology, which are applied in combustion air/combustion-air processing, charging system, combustion engine, etc., can solve the problems of energy consumption and carbon dioxide emission, and achieve the effect of improving combustion rate and preventing air pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

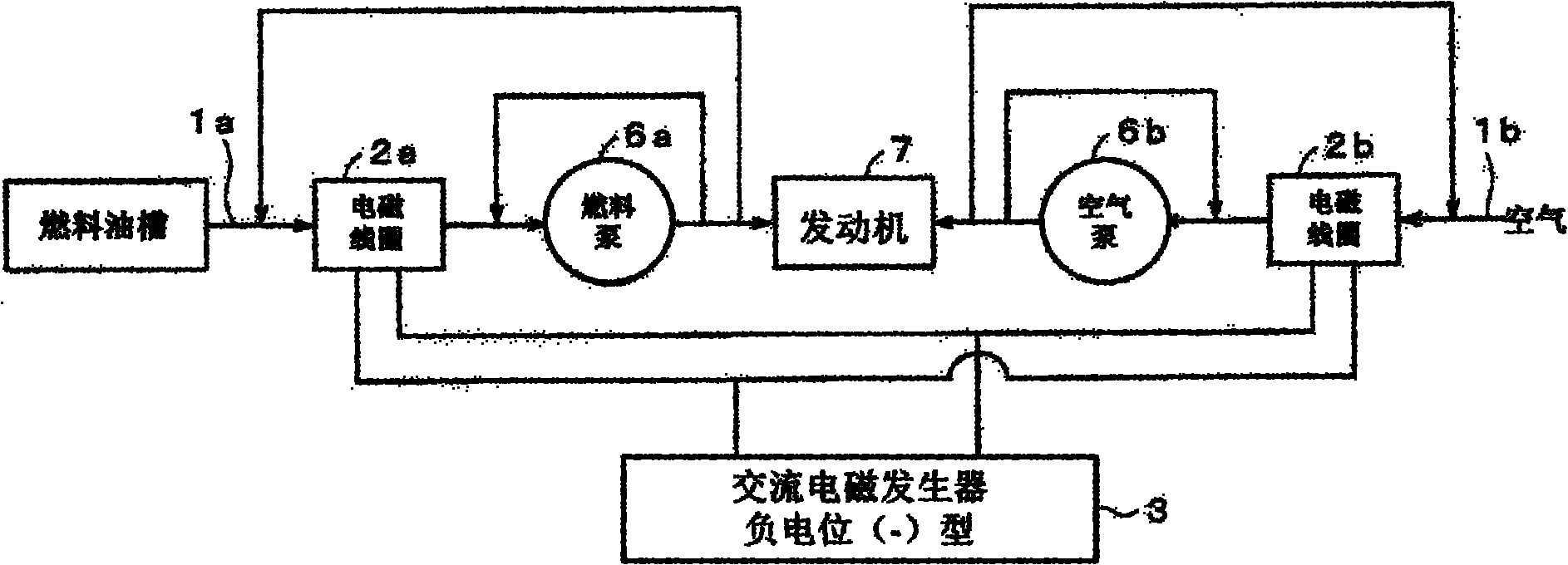

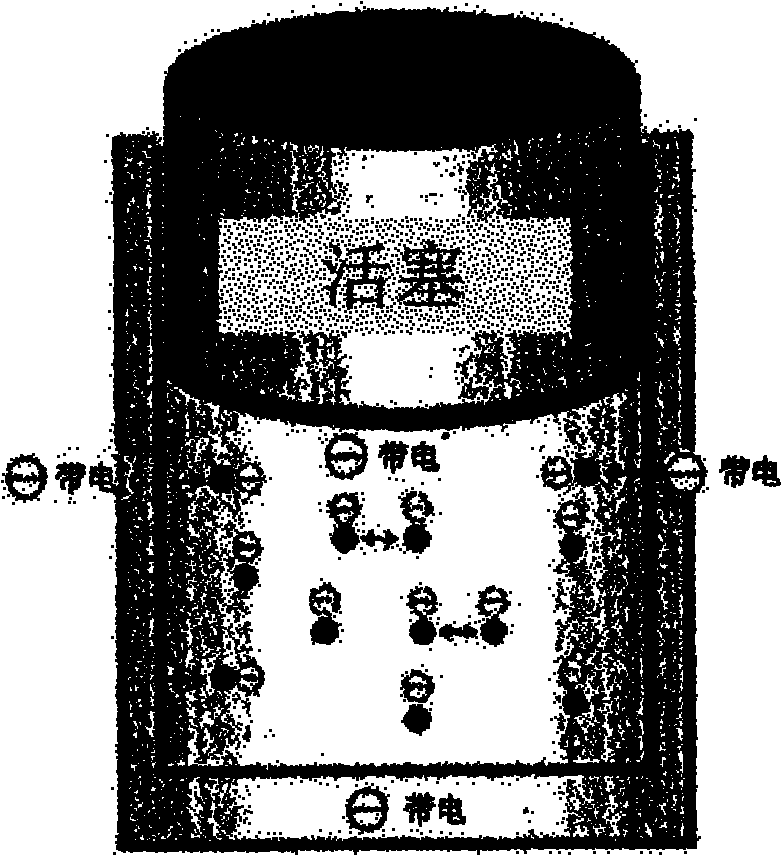

[0121] Example 1: Table 1 is in figure 1 In the system, the coil 2a is installed on the fuel supply line 1a of the engine 7; the ceramic radiation type electromagnetic coil module is installed on the air supply line 1b, and the electromagnetic generator in Figure 3 or Figure 4 is used to direct the coil 2a and the ceramic radiation type The electromagnetic coil module 2b outputs the following AC currents: (a) AC current with a single main frequency; the present invention can use one or more output waveform signals with a peak frequency range of 4000Hz to 25000Hz as needed; (b) ) Several kinds of mixed AC currents with different single frequencies; the present invention can use one or more output waveform signals with a peak frequency range of 4000Hz to 25000Hz as required; (c) Have the signal at 4000-25000Hz as shown in Figure 6 An alternating current whose frequency changes with time; the fuel and air are magnetized by the alternating magnetic field generated by the electromagn...

Embodiment 2

[0126] Example 2: Take figure 1 The shown system installs an electromagnetic coil 2a on the fuel supply pipe 1a of the engine 7 and an electromagnetic coil 2b on the combustion air supply pipe 1b. The electromagnetic coil 2b here is an electromagnetic coil module with a ceramic layer. The generator (negative potential type) supplies alternating currents of different intensities to the electromagnetic coil 2a and the electromagnetic coil 2b to test the magnetization effect of the output power of the present invention on the fuel. Among them, when the electromagnetic coil is not supplied with current, it can be regarded as "untreated" without magnetization for comparison. The calculation method of output power is W (watt) = the product of I (current) and V (voltage). The frequency of the AC current used in the test is the AC current within 4KHz-25KHz: (1) AC current with a single frequency; (2) Several mixed AC currents with different single frequencies; (3) Frequency with time ...

Embodiment 3

[0158] Example 3: Picture 10 for figure 1 A schematic cross-sectional view of an air cleaner 10 that provides combustion air to the engine 7 in the system shown. A filter element 11 is installed in the air cleaner, and a stainless steel metal mesh 12 with honeycomb-shaped openings and silver-plated surface is installed on the upper or lower part of the filter element. The metal mesh 12 is referred to in Table-9 and Table-10 for short. Metal mesh-silver'. Another type of mesh structure module is to arrange ceramic balls ('IonTechno Ball' manufactured by Furuya Institute of Technology Co., Ltd., Japan) with a diameter of approximately 5 mm on a stainless steel metal mesh in a go-board-like array. The arrangement density is approximately One particle in the range of 10mmX10mm. The metal mesh 12 equipped with ceramic balls is listed in Table 9, and is referred to as "metal mesh-ceramic" in Table 10. The negatively charged electromagnetic generator of Figure 3 is used in the test p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com