Continuous annealing furnace gas cleanliness detecting system

A continuous annealing furnace, furnace gas technology, applied in furnaces, heat treatment furnaces, furnace types, etc., to achieve the effect of reliable judgment basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

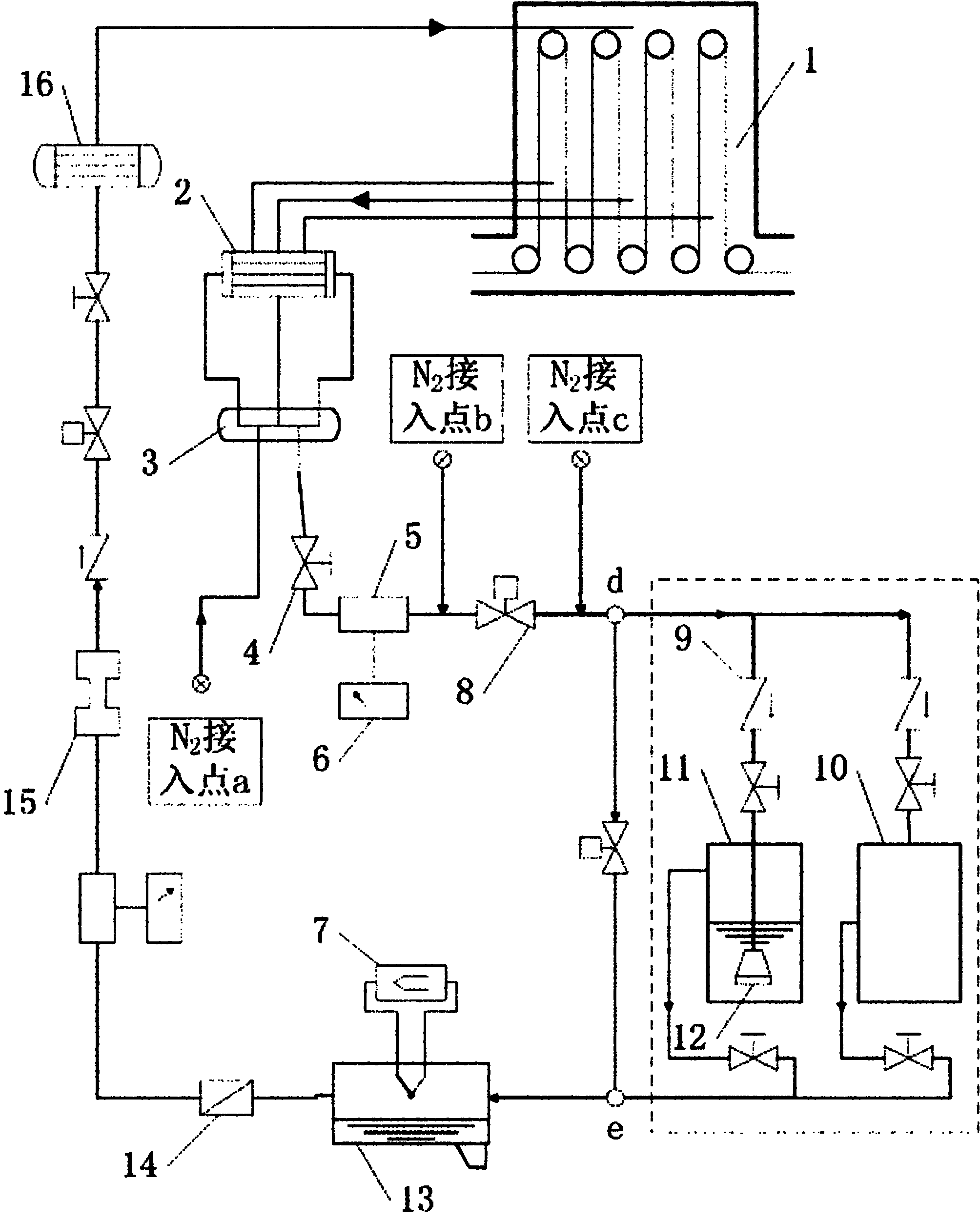

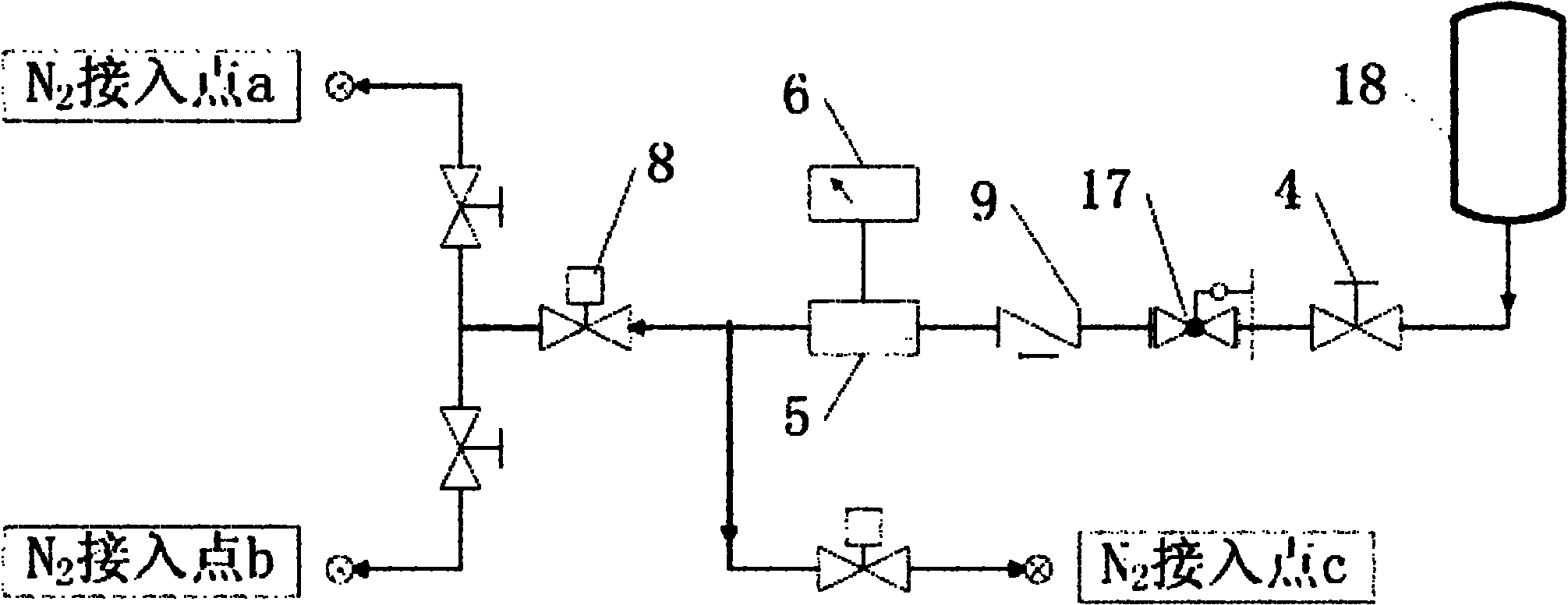

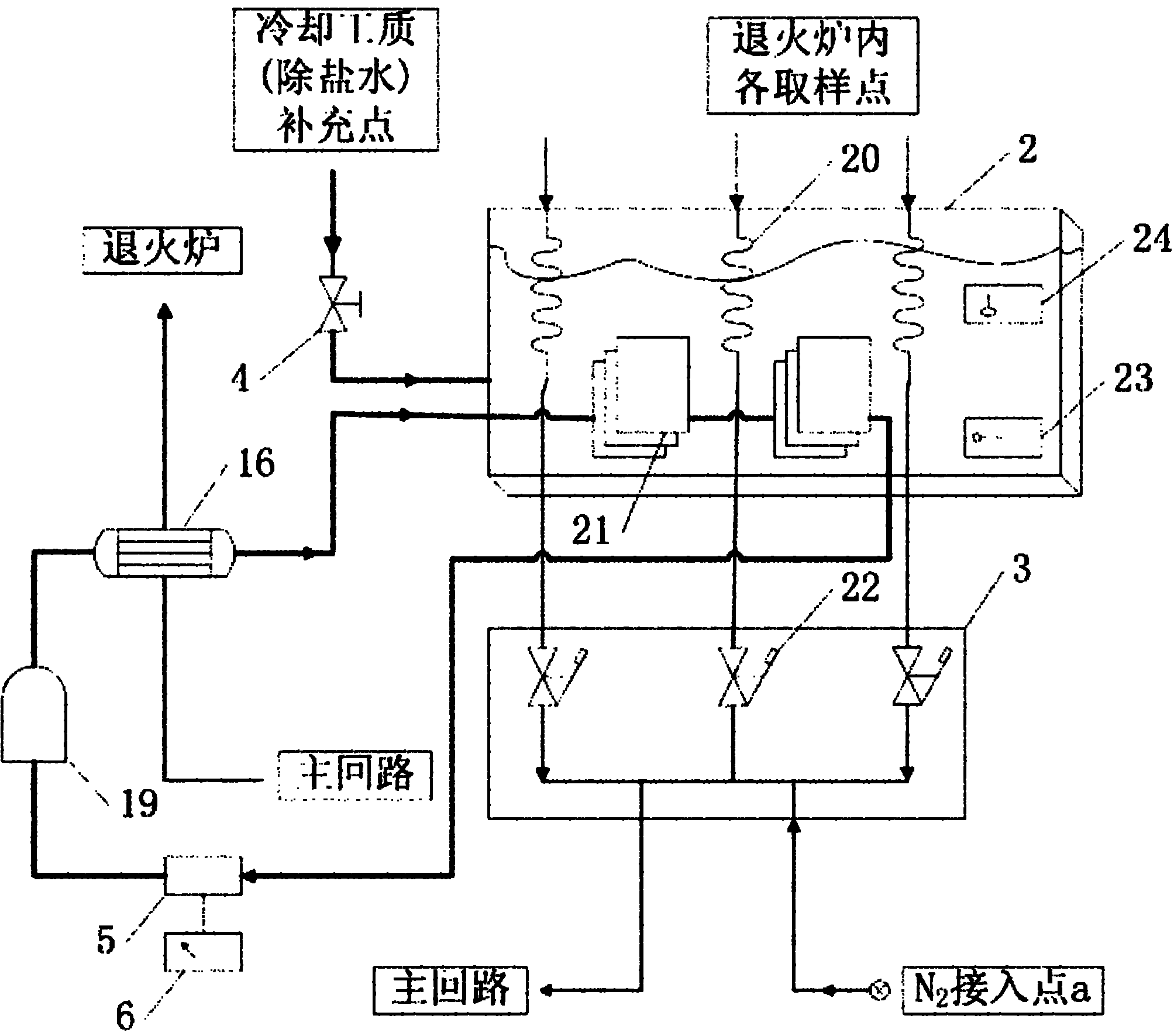

[0024] Example 1. Continuous annealing furnace atmosphere cleanliness detection system

[0025] The detection system for atmosphere cleanliness in a continuous annealing furnace provided by the present invention is mainly composed of a furnace gas sampling supervisor, a gas pollutant collector branch, and a metering and gas return supervisor. Wherein: the furnace gas sampling main pipe, its input end communicates with the annealing furnace chamber 1 through a pipeline, its output end is connected with the input end of the gas pollutant total collector branch through a pipeline, and is connected with the nitrogen purge circuit connected to the output. The output end of the gas pollutant collector branch is connected with the input end of the metering and gas return main pipe through a pipeline. The input end of the nitrogen purge circuit is connected to the nitrogen station through a pipeline; the nitrogen purge circuit is connected in parallel to the gas distributor 3 of the ...

Embodiment 2

[0054] Example 2. Application of the detection system for the cleanliness of the atmosphere in the continuous annealing furnace

[0055] The detection system provided by the present invention can be used for manual detection of the cleanliness of the atmosphere in the continuous annealing furnace in the field of medium and high-end automobile or household appliance panel production. The detection system is based on the following detection methods, specifically: Use a sampling metering pump to pump out the gas in the furnace chamber of the annealing furnace, and make the furnace gas pass through the collector according to the set flow rate, and various particles in the furnace gas will be blocked in the collector The sampling metering pump will automatically measure the volume of the collected furnace gas, and the controller will send the temperature and pressure signals measured by the instrument in front of the sampling metering pump to the computer for processing, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com