Method and apparatus for processing brittle material substrate

A brittle material substrate, brittle material technology, applied in stone processing tools, fine working devices, stone processing equipment, etc., can solve problems such as sudden breakage and inability to form scribe grooves, and achieve the effect of shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

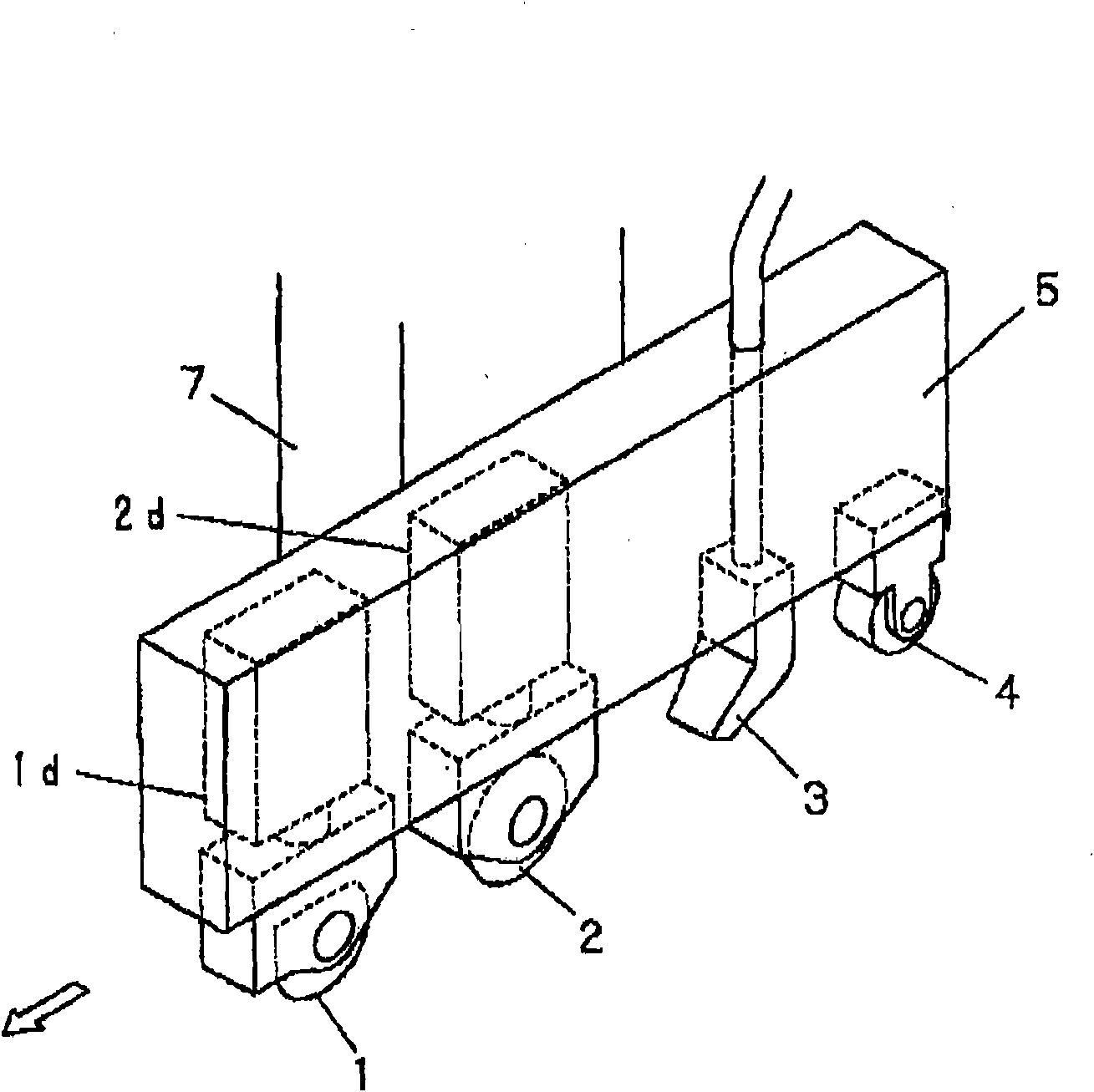

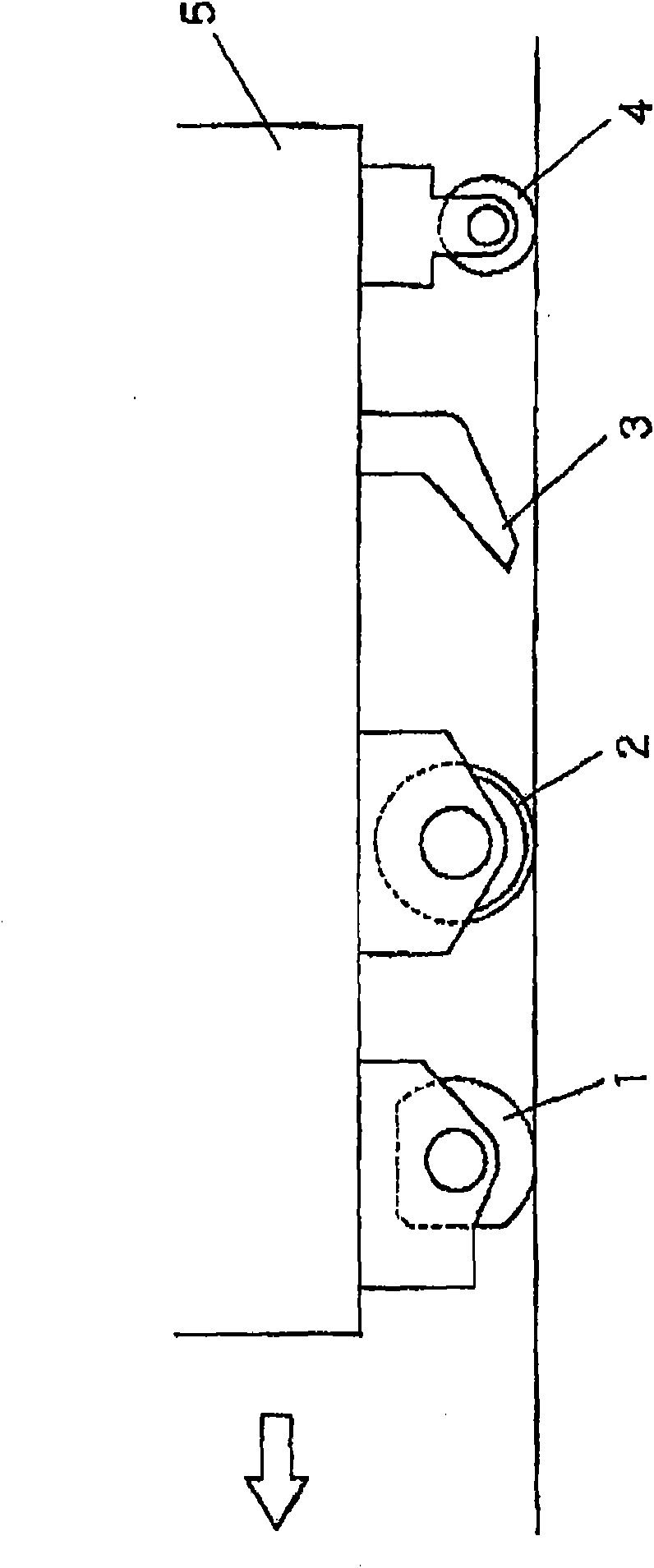

[0066] Hereinafter, the processing method of this invention is demonstrated in detail based on drawing which shows this embodiment.

[0067] figure 1 A perspective view showing an example of a processing device A used when implementing the processing method of the present invention. The processing apparatus A is equipped with the stage 10 which can move in a substantially horizontal direction (Y direction), and can rotate in a horizontal plane. The stage 10 is equipped with the vacuum suction mechanism (not shown) for holding the glass substrate W.

[0068] The bridge member 13 formed by the support columns 11 and 11 on both sides of the platform 10 and the guide rod 12 extending in the X direction is arranged to straddle the platform 10 and is formed to be movable by a moving mechanism not shown in the figure. in the Y direction. The slider 14 is attached so as to be movable by the guide 15 formed on the guide bar 12 and is moved in the X direction by the rotation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com