Diesel injector suitable for various fuels

A technology of fuel injector and diesel engine, which is applied in the direction of fuel injection device, machine/engine, charging system, etc., to achieve the effect of reducing processing cost, compact structure and simplifying processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

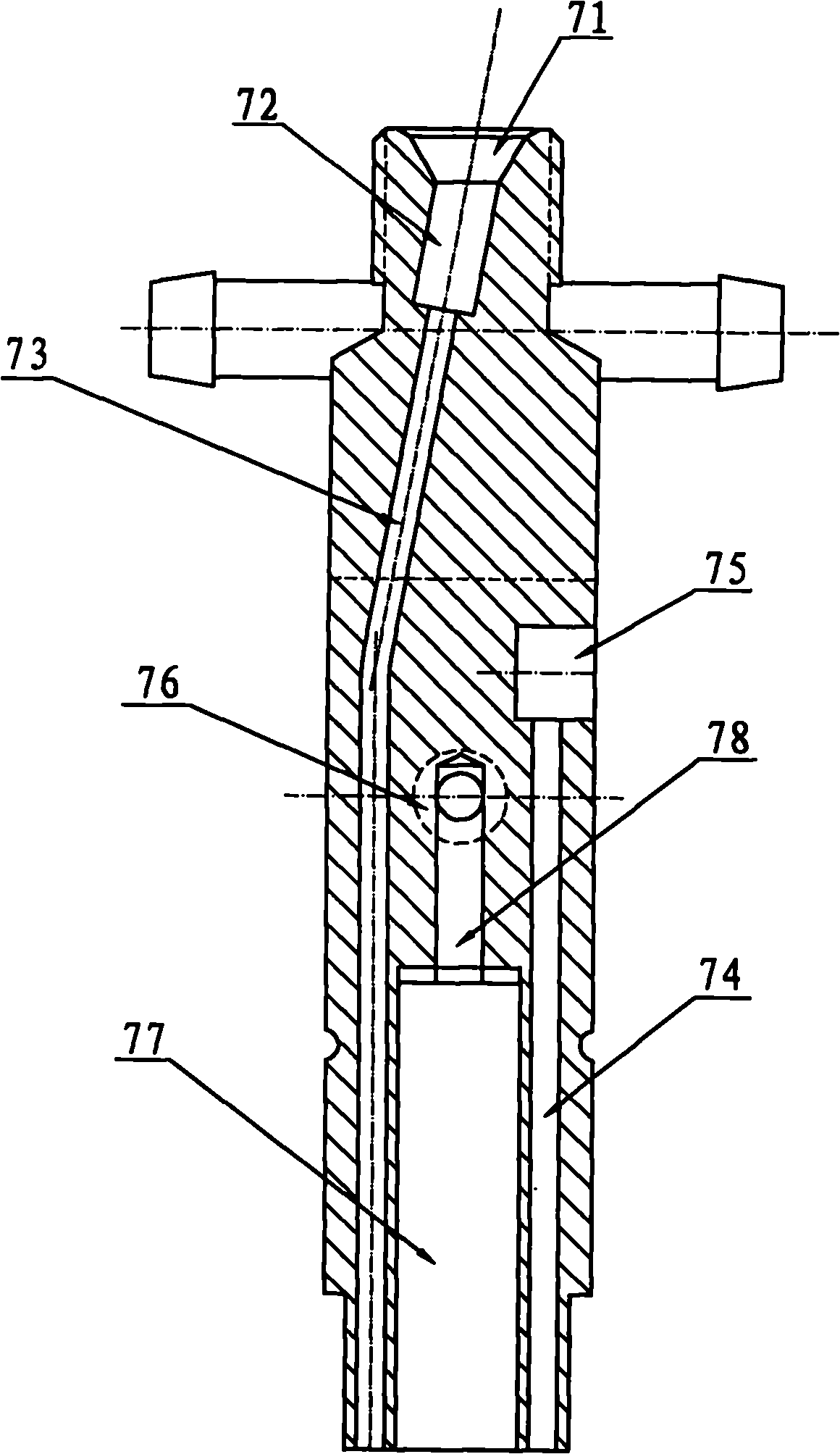

[0020] Embodiment 1: the diesel fuel injector applicable to multiple fuels, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it consists of fuel injector coupler 1, coupler fixing nut 2, transition plate 3, needle valve top seat 4, spring 5, pressure adjustment plate 6, fuel injector body 7, high-pressure oil pipe part 8 and oil return pipe 9 Composition: fuel liquid inlet 71, filter element hole 72, fuel upper passage 73, upper lubricating oil passage 74, oil inlet pipe seat hole 75, oil return pipe seat hole 76, spring hole 77 and oil return hole are arranged on the injector body 7 78, the fuel liquid inlet 71, the filter element hole 72 and the fuel upper passage 73 are connected, the upper lubricating oil passage 74 is connected with the oil inlet pipe seat hole 75, and the high pressure oil pipe part 8 is fixedly installed in the oil inlet pipe seat hole 75; the oil return pipe The seat hole 76 communicates with the oil return hole 78, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com