Novel liquid nitrogen cold assembly device

A new type of liquid nitrogen technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems affecting the quality of cold installation, corrosion of shaft parts or frosting, etc., to ensure cooling effect, avoid surface corrosion, strengthen The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

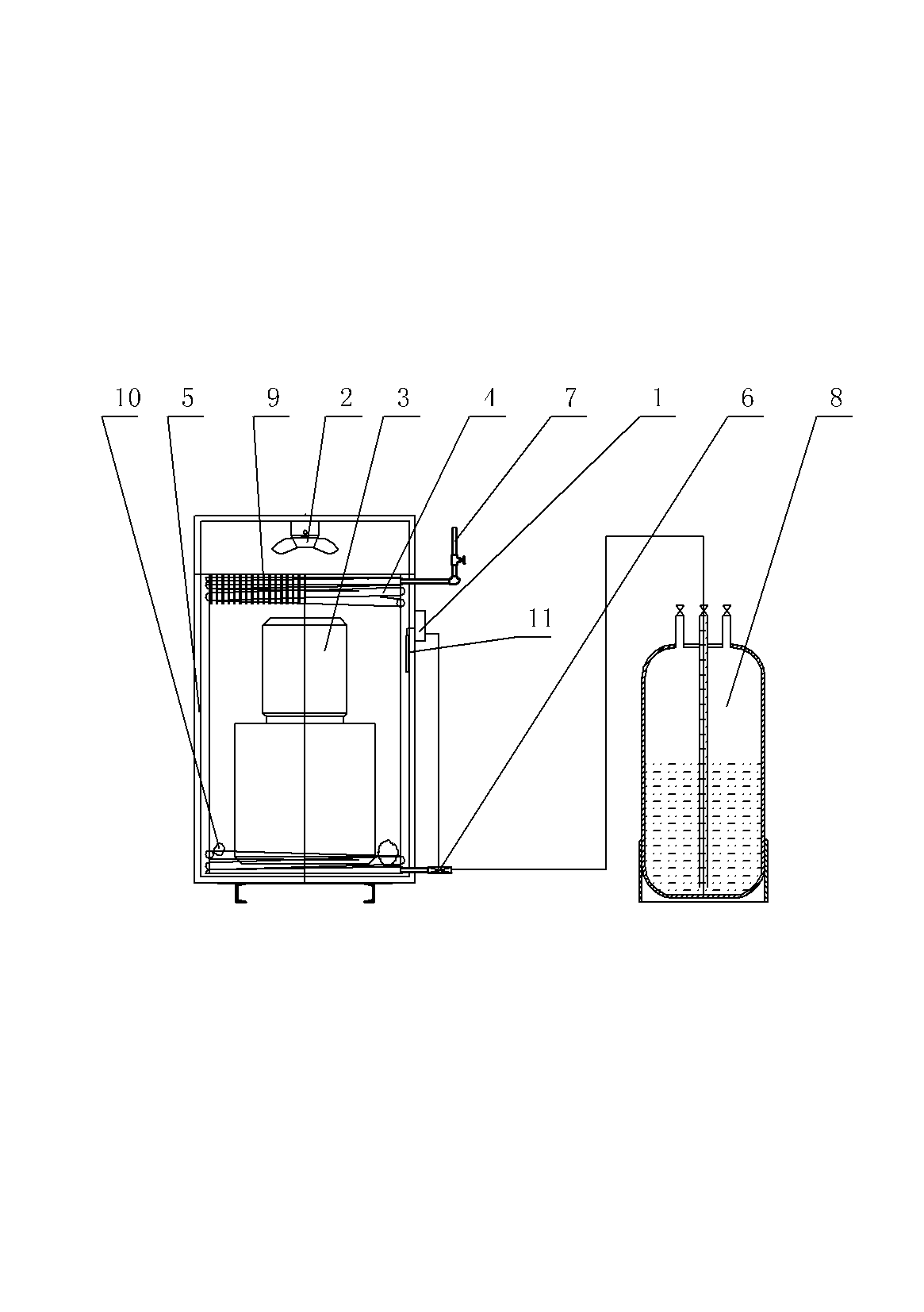

[0008] See figure 1 , The structure of the present invention includes a liquid nitrogen tank 8, a thermal insulation cooling box 5, an evaporator is installed in the thermal insulation cooling box 5, and the liquid nitrogen tank 8 is connected to the evaporator through a pipeline. The evaporator includes stainless steel tubes 4 and cooling fins 9; the stainless steel tubes 4 are arranged and installed vertically in a spiral shape along the heat insulation cooling box 5; the liquid nitrogen tank 8 is connected to the lower port of the stainless steel tube 4 through the pipeline and the throttle valve 6; the stainless steel tube 4 The upper port is connected with an exhaust pipe 7, and the exhaust pipe 7 passes through the side wall of the thermal insulation box 5; the heat sink 9 is installed outside the stainless steel pipe 4; the fan 2 is installed on the top of the thermal insulation cooling box 5; the thermal insulation cooling box A desiccant 10 is also placed in the 5; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com