Method for preparing premelted refining slag by using converter slag and aluminum slag

A technology of converter slag and refining slag, which is applied in the field of preparing premelted refining slag, can solve the problems of unfavorable natural resource protection and high energy consumption, achieve good desulfurization thermodynamic conditions, simple preparation process, and reduce oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

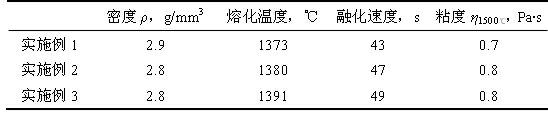

Embodiment 1

[0041] The specific process of preparing premelted refining slag from converter slag and aluminum slag is as follows:

[0042] (1) Selection of raw materials

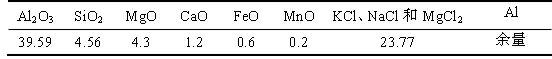

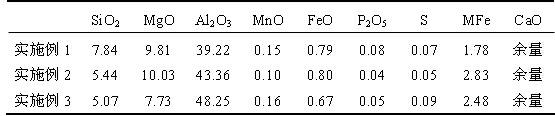

[0043] The components of converter slag and aluminum slag used are shown in Table 2 and Table 3.

[0044] (2) Ingredients

[0045] The mass ratio of converter slag to aluminum slag is 2.5:1.

[0046] (3) Smelting of pre-melted refining slag: The converter slag is melted in a high-temperature furnace, and the temperature is controlled at 1550°C to ensure its good fluidity. After the converter slag is completely melted, the aluminum slag is added in three batches, and the addition amount of each batch is respectively 50%, 25% and 25% of the total addition amount according to the mass ratio, and the time interval between each batch is 5min. Each batch of aluminum slag added is stirred with nitrogen to ensure uniform reduction reaction and promote the improvement of reaction speed.

[0047] (4) Separation of slag and ir...

Embodiment 2

[0056] The specific process of preparing premelted refining slag from converter slag and aluminum slag is as follows:

[0057] (1) Selection of raw materials

[0058] The components of converter slag and aluminum slag used are shown in Table 2 and Table 3.

[0059] (2) Ingredients

[0060] The mass ratio of converter slag to aluminum slag is 2.3:1.

[0061] (3) Smelting of pre-melted refining slag: The converter slag is melted in a high-temperature furnace, and the temperature is controlled at 1600°C to ensure its good fluidity. After the converter slag is completely melted, the aluminum slag is added in three batches, and the addition amount of each batch is respectively 50%, 25% and 25% of the total addition amount according to the mass ratio, and the time interval between each batch is 4min. Each batch of aluminum slag added is stirred with nitrogen to ensure uniform reduction reaction and promote the improvement of reaction speed.

[0062] (4) Slag and iron separation:...

Embodiment 3

[0066] The specific process of preparing premelted refining slag from converter slag and aluminum slag is as follows:

[0067] (1) Selection of raw materials

[0068] The components of converter slag and aluminum slag used are shown in Table 2 and Table 3.

[0069] (2) Ingredients

[0070] The mass ratio of converter slag to aluminum slag is 2.1:1.

[0071] (3) Smelting of pre-melted refining slag: The converter slag is melted in a high-temperature furnace. In order to ensure its good fluidity, the temperature is controlled at 1500°C. After the converter slag is completely melted, add the aluminum slag in three batches, the amount of each batch is 50%, 25% and 25% of the total amount by mass ratio, and the time interval between each batch is 3min. Each batch of aluminum slag added is stirred with nitrogen to ensure uniform reduction reaction and promote the improvement of reaction speed.

[0072] (4) Separation of slag and iron: After the last batch of aluminum slag is add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com