Grain refinement technology of silver-nickel electrical contact material and grain refinement technology of silver tin oxide electrical contact material

An electrical contact material, grain refinement technology, applied in the direction of contacts, circuits, electrical switches, etc., can solve the problems of poor compactness, difficult processing, low material strength, etc. Various properties, obvious effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

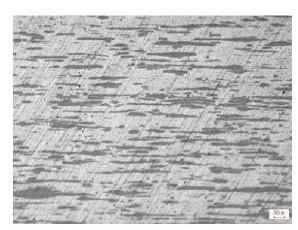

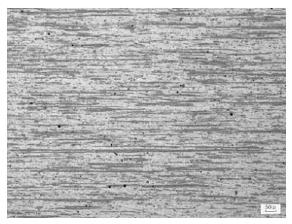

[0044] Example 1: Take the AgNi10 wire with a diameter of Ф0.6mm 3kg, the 0.6mm~2mm clean corner wire produced in the process 3kg, the wire diameter within the range of 2.0mm 9kg, cut with a shearing machine to approximately 1cm-5cm length The short wire is heat treated under a hydrogen atmosphere at a constant temperature of 550℃~600℃ for 1.5 hours to 2.0 hours, and compressed into a Ф80mm-spindle on a hydraulic press with a pressure of 25 MPa -30MP. The spindle is 550℃ under a hydrogen atmosphere. After heat treatment at a constant temperature of ~600℃ for 1.5 hours to 2.0 hours, the ingot is subjected to 2~3 upsetting treatments before extrusion, the first upsetting to 82mm, the second upsetting to 84mm, the third upsetting Thick to 85mm, in a hydrogen protective atmosphere, heat the spindle to 850℃, put the spindle into the extruded copper with a diameter of Ф90mm, heat extrude the wire with a diameter of Ф6mm (extrusion ratio is 225), and finally draw to Ф1.88mm specificat...

Embodiment 2

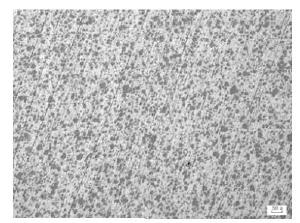

[0049] Example 2: Take AgSnO 2 (15) Wire diameter Wire diameter Ф0.6mm 3kg, 0.6mm~2mm clean corner material produced in the process 3kg, wire diameter within the range of 2.0mm 9kg, cut to approximately 1cm-5cm length with a shearing machine The short wire is heat treated at a constant temperature of 800℃~900℃ for 1.5 hours to 3.0 hours, and compressed into a Ф80mm spindle on a hydraulic press with a pressure of 25 MPa -30MP. The spindle is heat treated at a constant temperature of 800℃~900℃ for 1.5 hours. After hours to 3.0 hours, the spindle is subjected to 3 hot upsetting treatments before extrusion, the first upsetting to 82mm, the second upsetting to 84mm, and the third upsetting to 85mm. Under a hydrogen atmosphere, the spindle Heat to 850℃, put the spindle into extruded copper with a diameter of Ф90mm, heat extrude the wire with a diameter of Ф6mm (extrusion ratio is 225), and finally draw to Ф1.88mm to make the corresponding rivets specification.

[0050] The comparison ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com