Method for modifying composite surface of carbon fiber

A composite surface and carbon fiber technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as poor microbial fixation, improve microbial fixation performance, and The effect of development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Soak the high-strength polyacrylonitrile-based carbon fiber (PAN-CF, T300) in acetone to remove the surface epoxy resin sizing agent at room temperature, rinse with distilled water and dry; then immerse the CF with the sizing agent removed in concentrated nitric acid constant temperature boiling water Take it out after heating the bath for 0.5-2h, rinse it repeatedly with distilled water until the pH value of the cleaning solution is 7, and then dry it; finally, immerse the CF oxidized by nitric acid in a CaCl2 solution with a concentration of 0.1-0.3mol / L for 5-6h, take it out Then rinse with distilled water and dry.

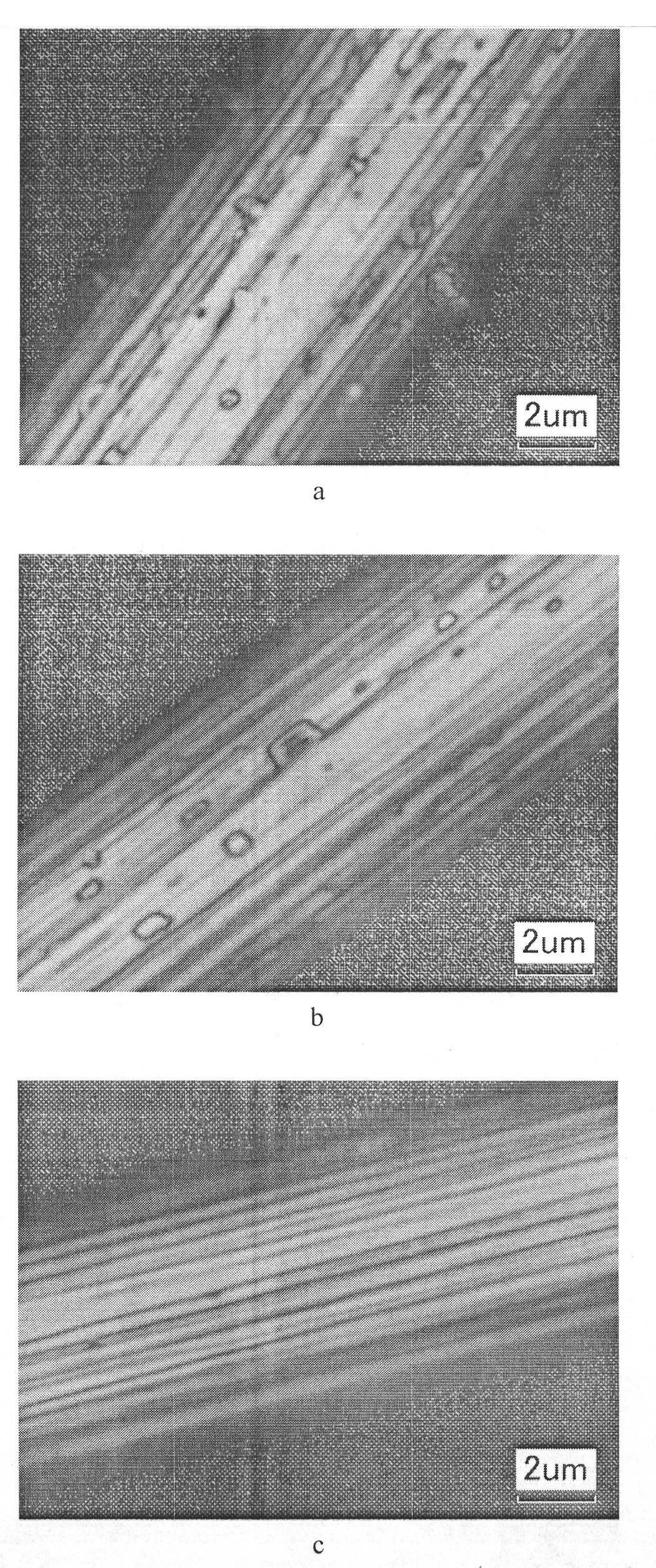

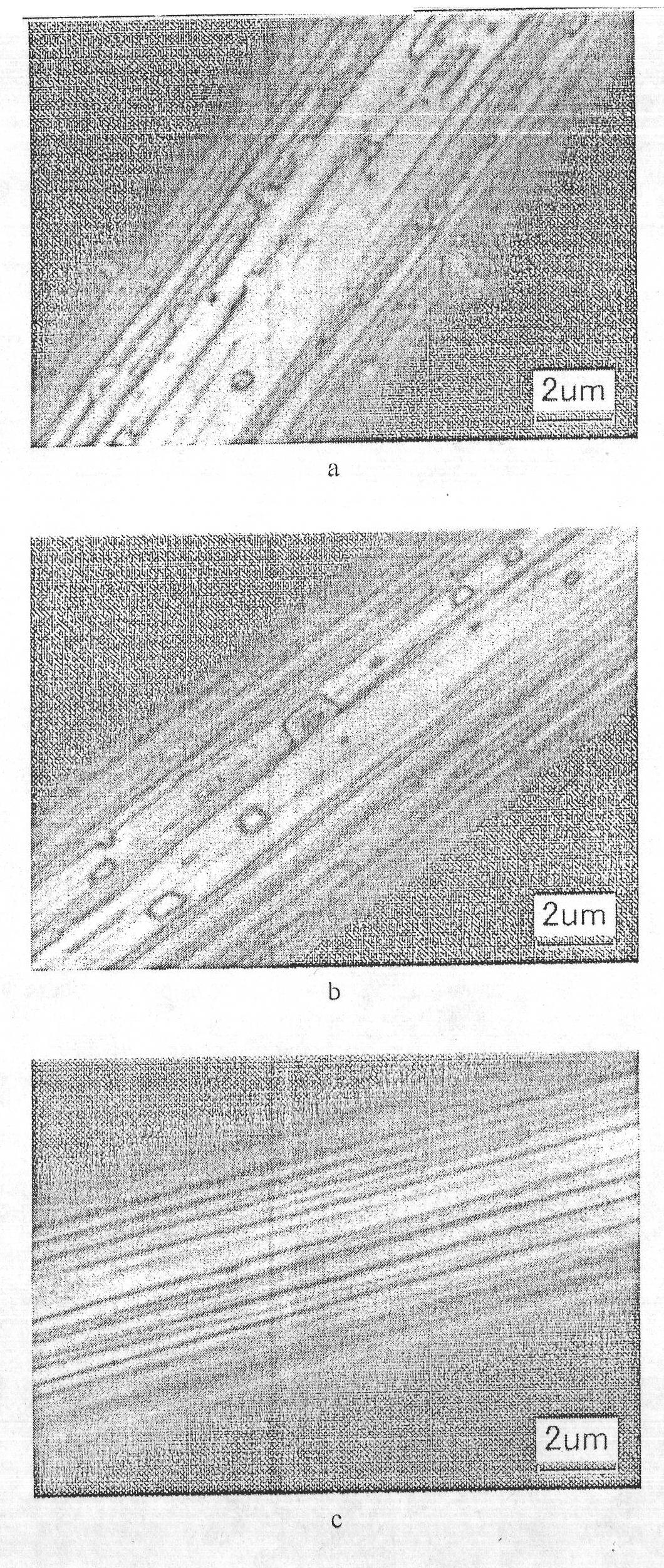

[0015] The obtained CF test results after surface modification are as follows: the total amount of oxygen-containing functional groups on the surface is 24.13%, the equilibrium water content is 6.07%, and the biofilm fixation amount is 229.6%. Its LCM photo as figure 1 Shown in a.

Embodiment 2

[0017] Soak the high-strength polyacrylonitrile-based carbon fiber (PAN-CF, T300) in acetone to remove the surface epoxy resin sizing agent at room temperature, rinse with distilled water and dry; then immerse the CF with the sizing agent removed in concentrated nitric acid constant temperature boiling water Take it out after heating in the bath for 1-3 hours, rinse repeatedly with distilled water until the pH value of the cleaning solution is 7, and then dry; finally, immerse the CF oxidized by nitric acid in FeCl3 solution with a concentration of 0.1-0.3mol / L for 4-5 hours, take it out Then rinse with distilled water and dry.

[0018] The obtained CF test results after surface modification are as follows: the total amount of oxygen-containing functional groups on the surface is 20.85%, the equilibrium moisture content is 5.18%, and the biofilm fixation amount is 188.0%. Its LCM photo as figure 1 Shown in b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com