Tinned copper alloy bar with excellent abrasion resistance, insertion properties, and heat resistance

A copper alloy and tin-plating technology, which is applied to contact parts and other directions, can solve problems such as heat resistance degradation and achieve excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

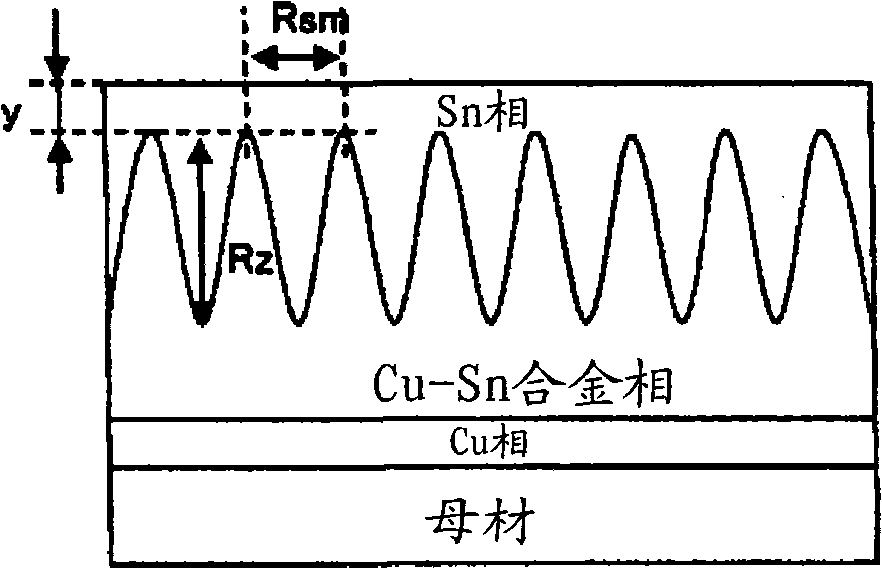

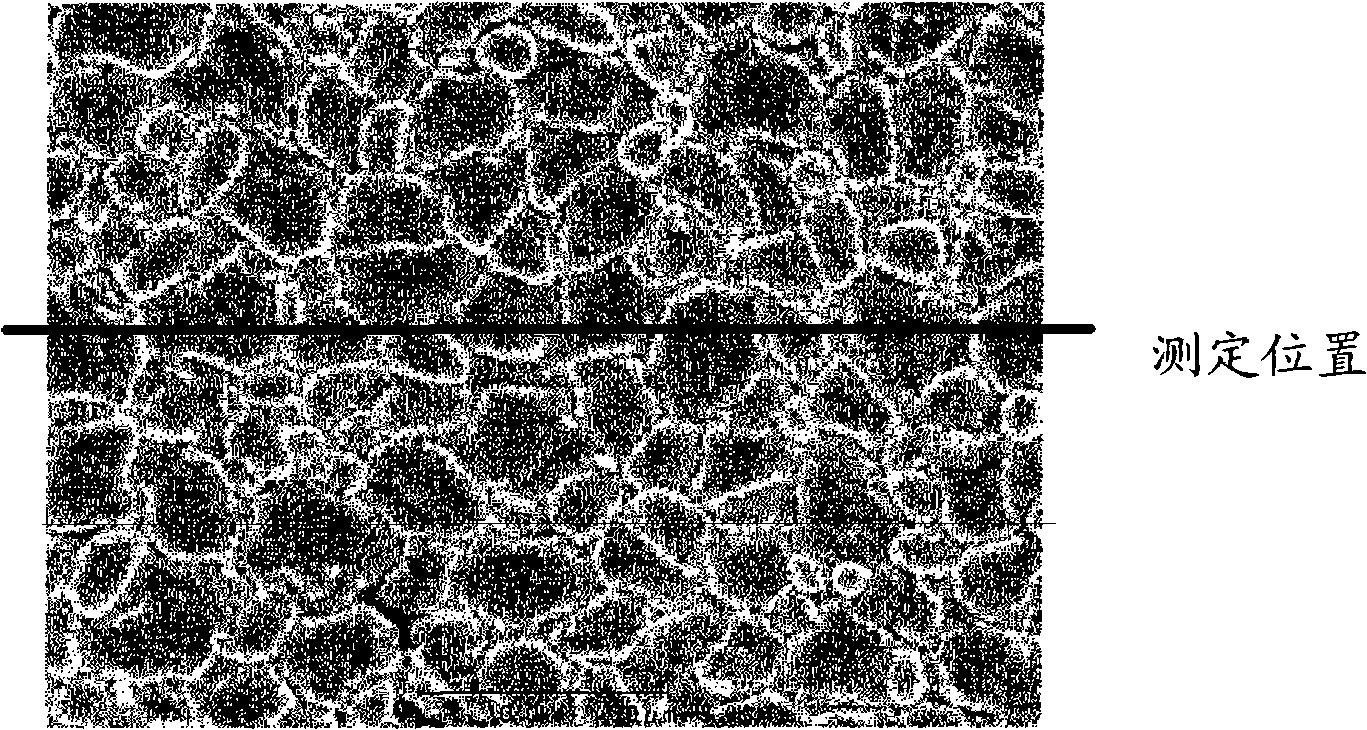

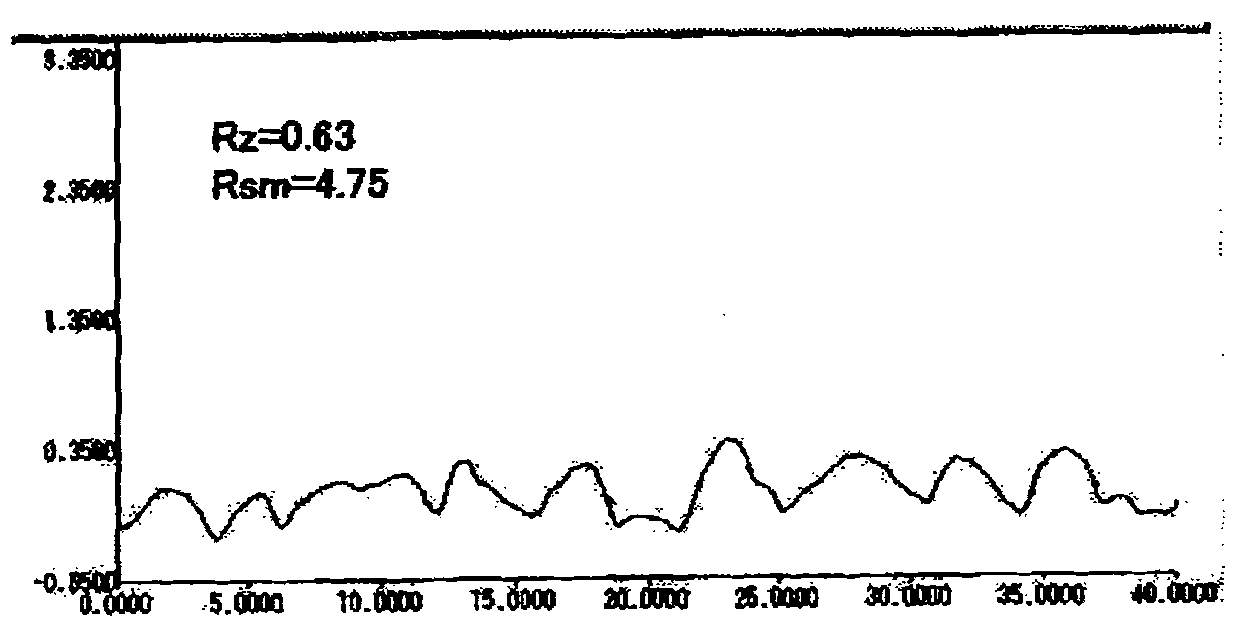

Method used

Image

Examples

Embodiment

[0080] The production examples of the copper alloy tin-plated bar of the present invention and the results of characteristic tests are shown below, but these are provided for better understanding of the present invention and its advantages, and are not intended to limit the present invention.

[0081] (a) base material

[0082] On a copper alloy composed of Cu-35%Zn (thickness 0.32mm, tensile strength 540Mpa, 0.2% endurance 510Mpa, Young's modulus 103GPa, electrical conductivity 26%IACS, Vickers hardness 171Hv) , perform Ni plating, bottom layer copper plating, Sn plating, and implement remelting treatment in the following order. The above-mentioned Vickers hardness is a value obtained by measuring a cross-section perpendicular to the rolling direction of the base material in accordance with JIS Z 2244.

[0083] (b) Plating treatment

[0084] (Electrolytic Degreasing Sequence)

[0085] Electrolytic degreasing is carried out in an alkaline aqueous solution with the sample as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com