Block copolymer composition, method for producing the same, and film of the same

A technology of block copolymer and composition, which is applied in the field of block copolymer composition, its preparation and film, and achieves good productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

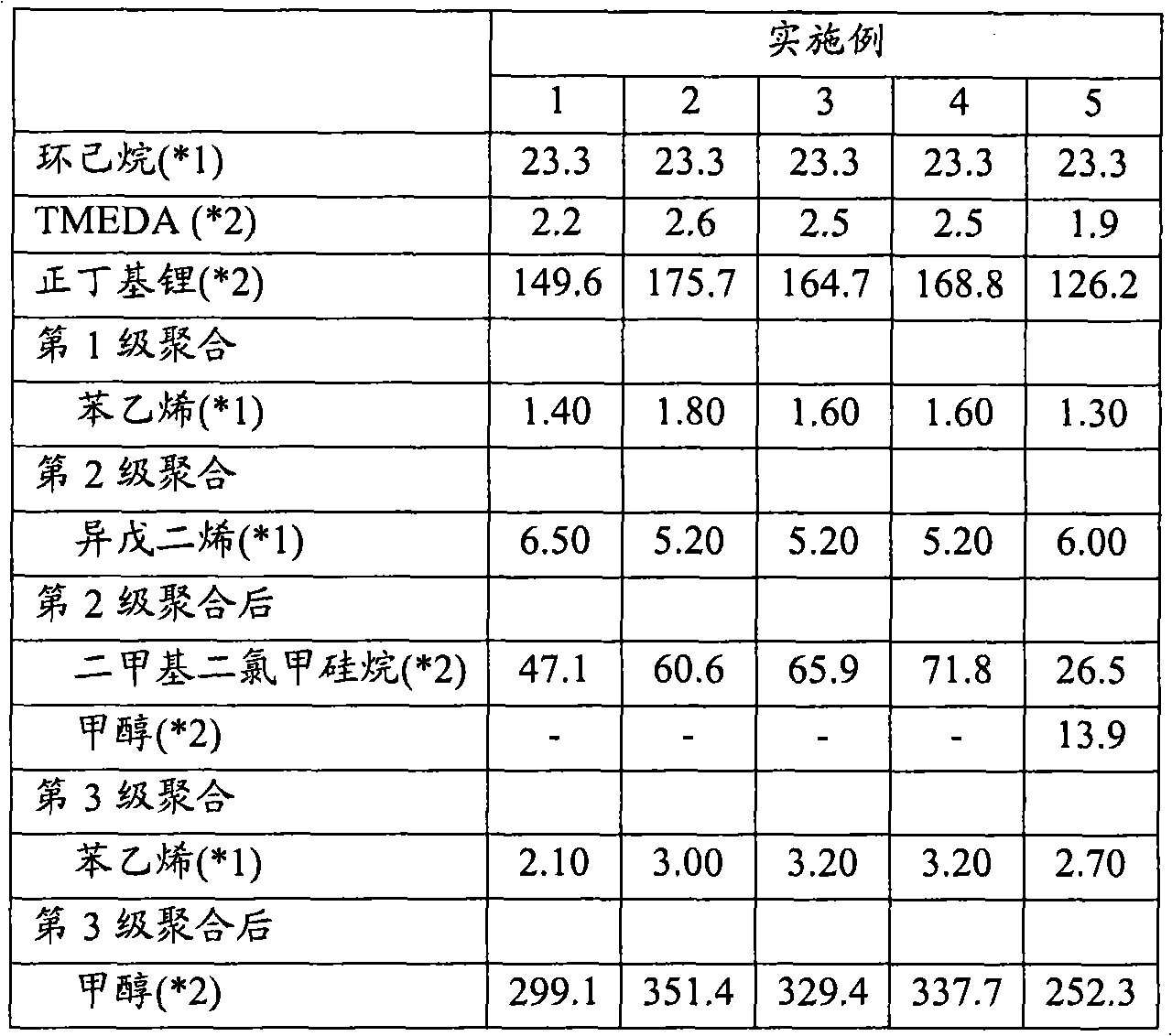

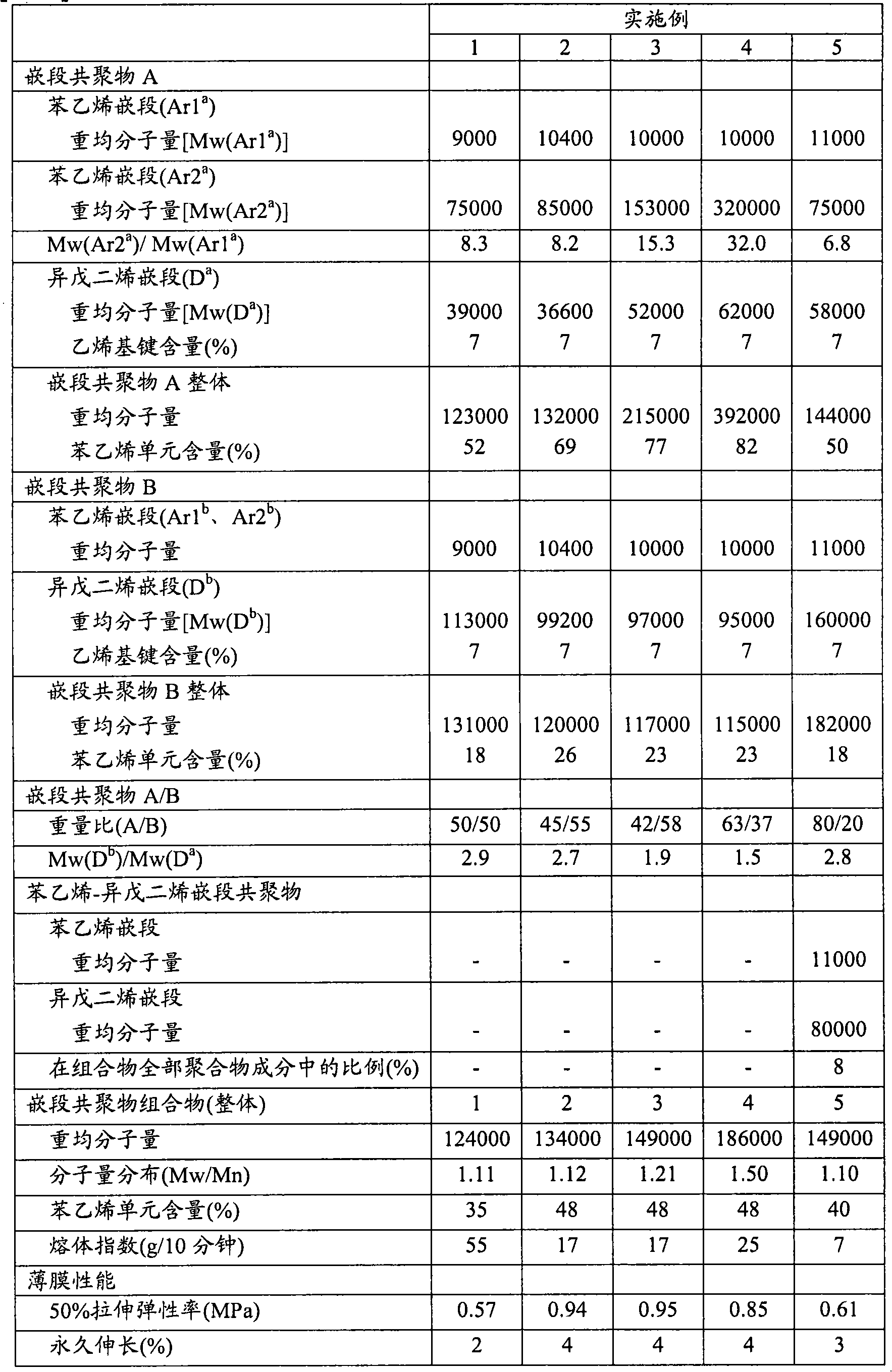

[0153] Add 23.3kg of cyclohexane, 2.2mmol of N,N,N',N'-tetramethylethylenediamine (hereinafter referred to as "TMEDA") and 1.40kg of styrene in the pressure reactor, After stirring at 40°C, 149.6 mmol of n-butyllithium was added, and the mixture was polymerized for 1 hour while raising the temperature to 50°C. The polymerization conversion rate of styrene was 100%.

[0154] Next, while controlling the temperature to keep it at 50-60°C, 6.50 kg of isoprene was continuously added to the reactor within 1 hour. After the addition of isoprene was completed, polymerization was further carried out for 1 hour. The polymerization conversion rate of isoprene was 100%.

[0155] Next, 47.1 mmol of dimethyldichlorosilane was added as a coupling agent, and a coupling reaction was performed for 2 hours to form a styrene-isoprene-styrene block copolymer as a block copolymer B.

[0156] Then, the temperature was controlled so as to be maintained at 50 to 60° C., and 2.10 kg of styrene was c...

Embodiment 2~4

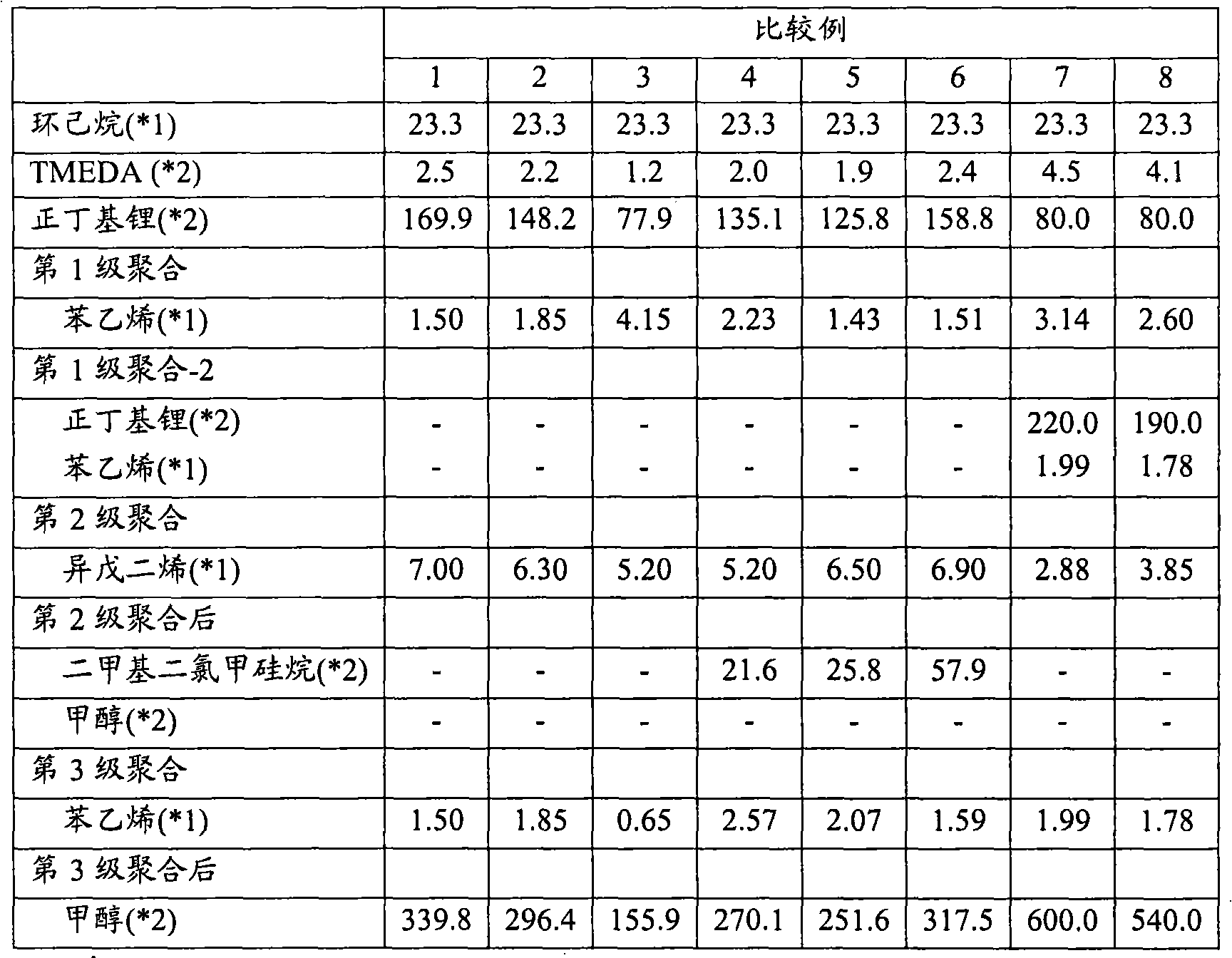

[0168] The amounts of styrene, n-butyllithium, TMEDA, dimethyldichlorosilane and methanol are shown in Table 1 respectively, and the reaction is carried out in the same manner as in Example 1 except for the changed part, and a part of the prepared reaction solution is taken out , The same measurement as in Example 1 was carried out. The measured values are shown in Table 2.

[0169] The following operations were the same as in Example 1, and block copolymer compositions 2 to 4 were recovered and pelletized. Using the pellets, the melt indices of block copolymer compositions 2-4 were measured. The results are shown in Table 2.

[0170] In addition, films of block copolymer compositions 2 to 4 were prepared from the above pellets. The same measurement as in Example 1 was performed on the film. The results are shown in Table 2.

Embodiment 5

[0172] Add 23.3kg of cyclohexane, 1.9mmol of TMEDA and 1.30kg of styrene to the pressure reactor, stir at 40°C, add 126.2mmol of n-butyllithium, and let the The polymerization was carried out for 1 hour. The polymerization conversion rate of styrene was 100%.

[0173] Next, while controlling the temperature so as to keep it at 50-60°C, 6.00 kg of isoprene was continuously added to the reactor within 1 hour. After the addition of isoprene was completed, polymerization was further carried out for 1 hour. The polymerization conversion rate of isoprene was 100%.

[0174] Next, 26.5 mmol of dimethyldichlorosilane was added as a coupling agent, and a coupling reaction was performed for 2 hours to form a styrene-isoprene-styrene block copolymer as a block copolymer B.

[0175] Here, some of the living ends of the styrene-isoprene block copolymer were deactivated by adding 13.9 mmoles of methanol to the reactor. Then, the temperature was controlled so as to keep it at 50-60° C., a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com