Exactly temperature-measuring and sampling system of molten steel and method thereof

An accurate temperature measurement and sampling system technology, applied in sampling devices, thermometers, measuring devices, etc., can solve the problems of fluctuation of appearance components, poor accuracy of temperature values, affecting accuracy, etc., to improve control and accuracy, and eliminate system accidents. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of the present utility model is described in detail below in conjunction with accompanying drawing.

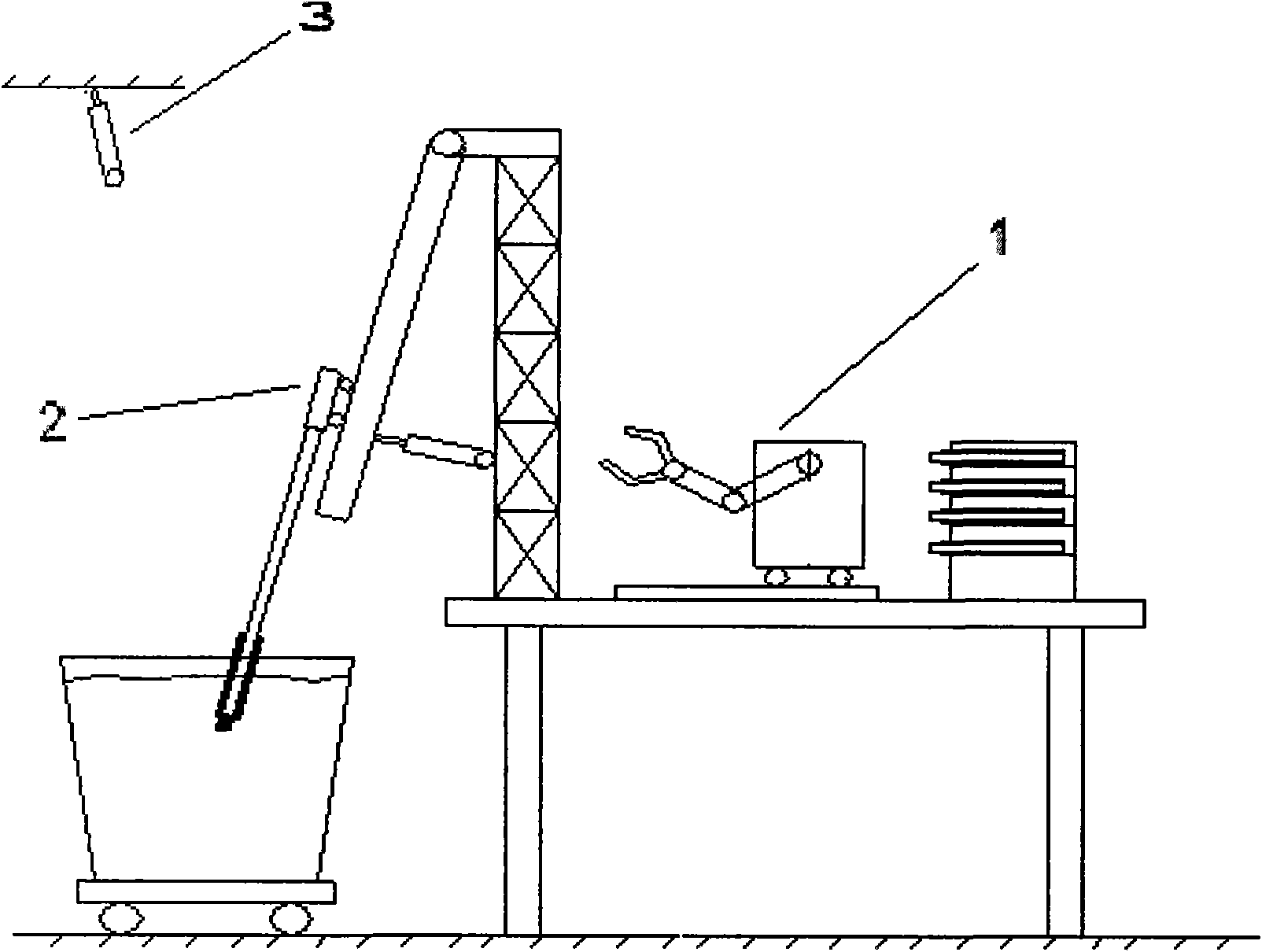

[0017] This precise automatic temperature measurement and sampling method mainly relies on the infrared liquid level detection device 3 to accurately detect the molten steel liquid level and calculate the depth of the gun, the intelligent robot 1 automatically inserts and removes the temperature measurement sampling probe, and the servo motor accurately controls the automatic temperature measurement and sampling gun 2. The reasonable combination of the three deep systems can achieve the purpose of accurate temperature measurement and sampling operation.

[0018] When the molten steel enters the station and the system collects the signal of the ladle being in place, the infrared liquid level detection device measures the liquid level of the molten steel, and stores the measurement results to the remote control computer. At this time, the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com