Method for preparing flocculant for treating papermaking black liquor by using waste collagen

A technology for papermaking black liquor and flocculant, which is applied in the field of flocculant preparation and treatment of waste water, can solve problems such as environmental pollution, waste of resources, and reduce the processing load of biochemical engineering, and achieve the effects of low price, reducing pollution load and shortening treatment period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 50 parts of waste pig skin scraps to 200 parts of water and soak at room temperature for 9 hours, transfer to a reaction kettle with a stirrer and a thermometer, then add 0.3 parts of 2709 protease, stir and react at a temperature of 45°C for 3.5 hours, and then adjust the pH to 4.0 and Stir and react at 70-75°C for 2-3 hours; cool down to 55°C, adjust the pH to 8.0, add 0.8 parts of 3-chloro-2-hydroxypropyltrimethylammonium chloride, stir for 7 hours, filter , rinse with water until there is no obvious residue on the surface of the skin collagen flocculant, dry at 50°C for 8 hours, and crush to 0.1-0.15mm.

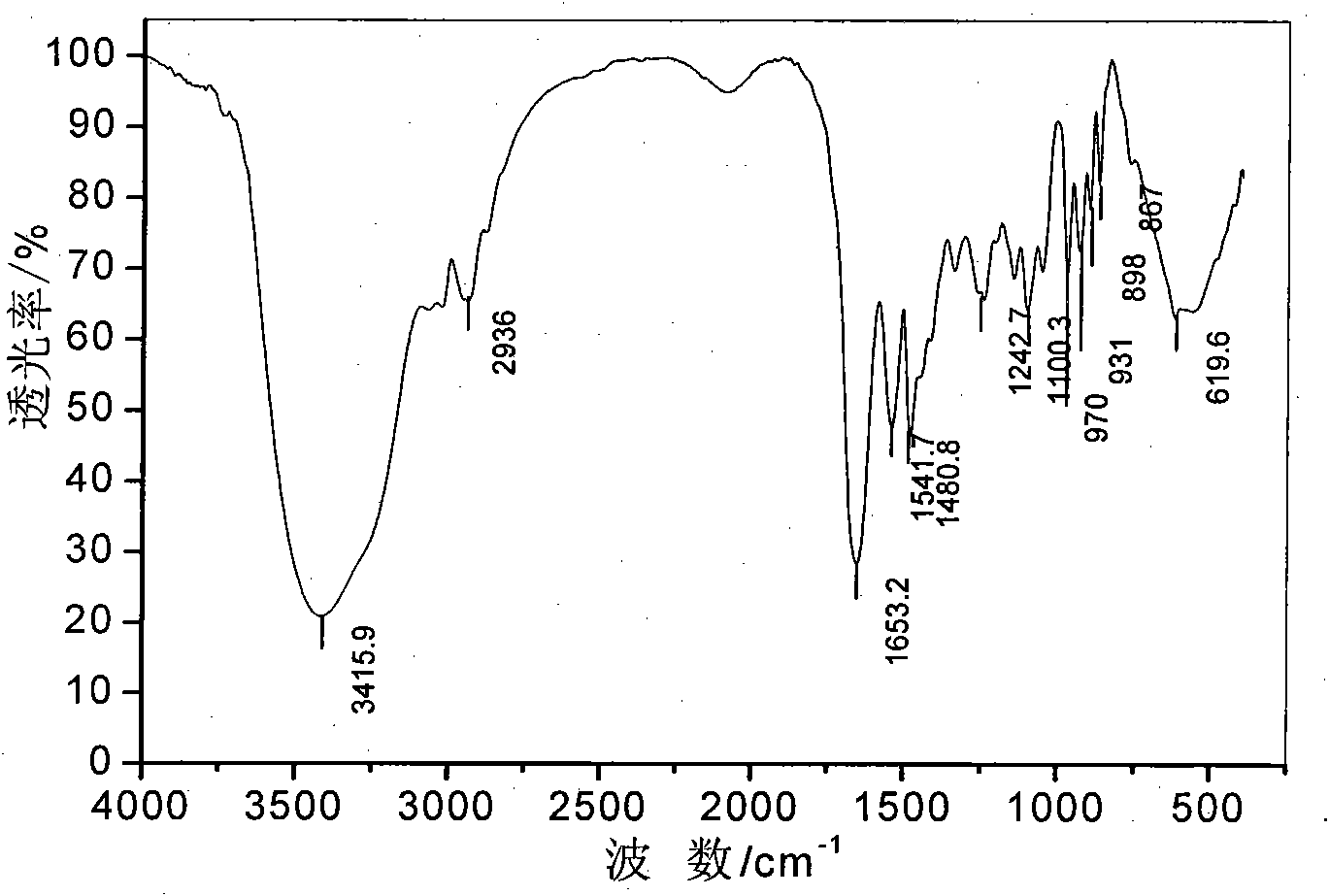

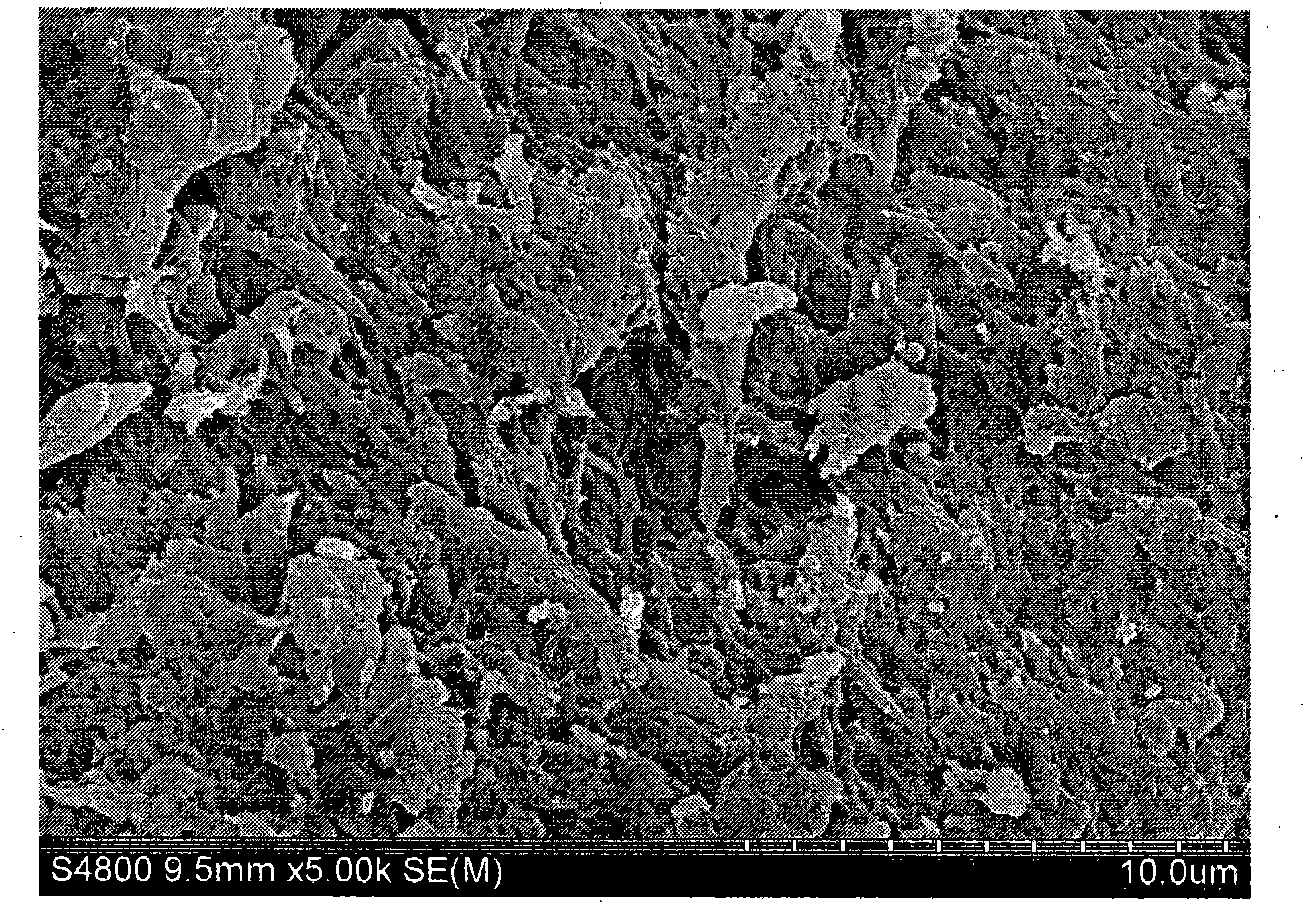

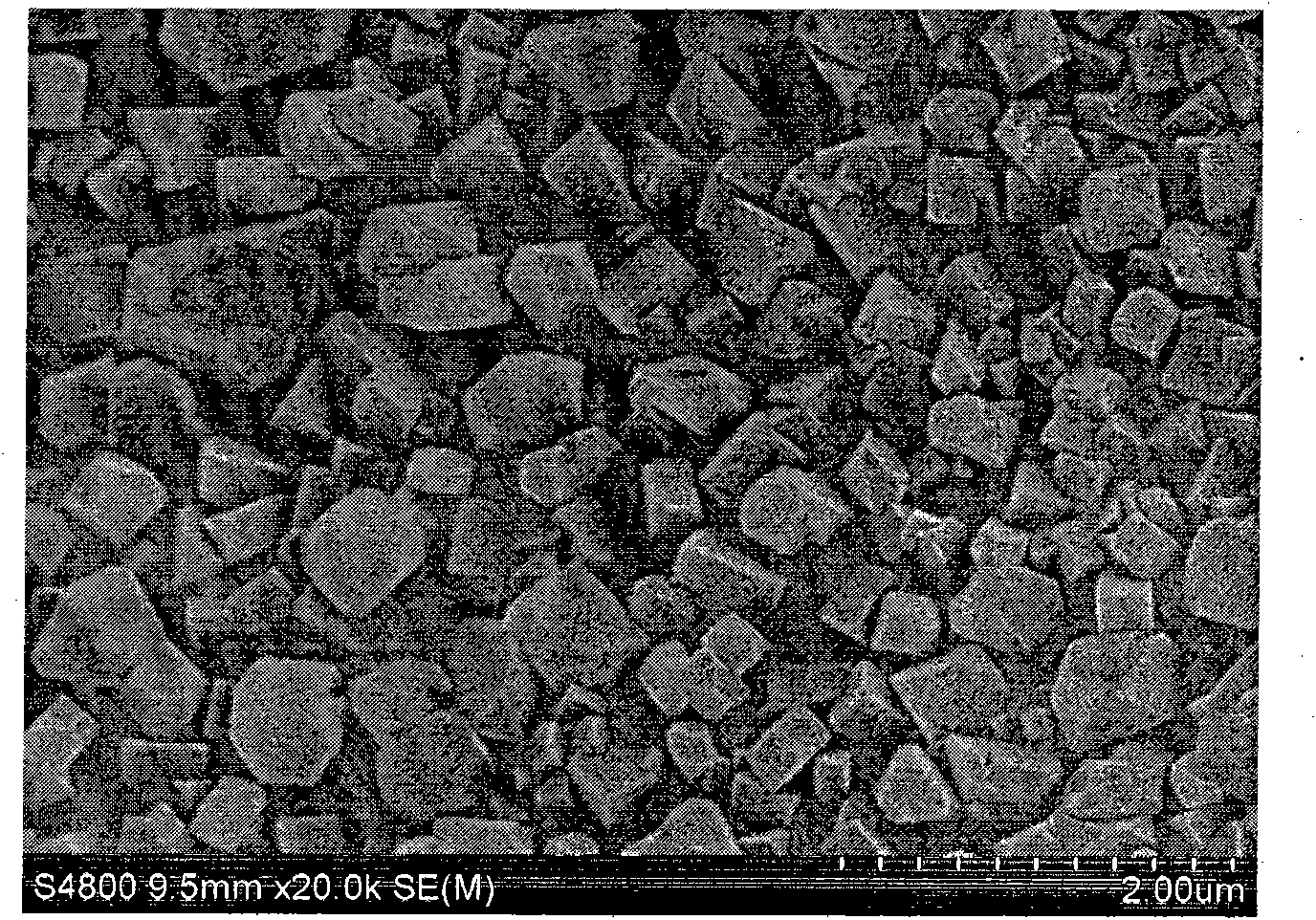

[0029] The infrared spectrogram of the prepared pigskin collagen base papermaking black liquor flocculant is as follows figure 1 As shown, its scanning electron microscope image is shown in figure 2 , 3 shown.

Embodiment 2

[0031] Add 60 parts of waste cowhide into 250 parts of water and soak at room temperature for 12 hours, transfer to a reaction kettle with a stirrer and a thermometer, then add 0.6 parts of 2709 protease, stir and react at a temperature of 50°C for 4 hours, and then mix the mixture between pH 4.5 and 80 Stir and react at ~85°C for 2.5 hours; cool down to 60°C, adjust the pH to 8.5, add 1.1 parts of 3-chloro-2-hydroxypropyltrimethylammonium chloride, stir for 8 hours, filter, and rinse with water Until there is no obvious residue on the surface of the skin collagen flocculant, dry it at 50°C for 8 hours and crush it to 0.1-0.15mm.

Embodiment 3

[0033] Add 70 parts of waste sheepskin scraps to 250 parts of water and soak at room temperature for 8 hours, then transfer to a reaction kettle with a stirrer and a thermometer, then add 0.5 parts of 2709 protease, stir and react at a temperature of 47°C for 3 hours, and then adjust the temperature between pH 4.0 and 75 Stir and react at ~80°C for 2.5 hours; cool down to 55°C, adjust the pH to 8.3, add 1.2 parts of 3-chloro-2-hydroxypropyltrimethylammonium chloride, stir and react for 6 hours, filter, and rinse with water Until there is no obvious residue on the surface of the skin collagen flocculant, dry it at 55°C for 7 hours and crush it to 0.1-0.15mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com