Polyolefin composite fiber

A composite fiber and polyolefin technology, applied in fiber treatment, fiber chemical characteristics, conjugated synthetic polymer artificial filament, etc., can solve problems such as hygroscopicity, poor dyeability, strong waxy feeling, and static charge accumulation in fibers, etc., to achieve Increased added value, reduced production costs, and odor-eliminating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

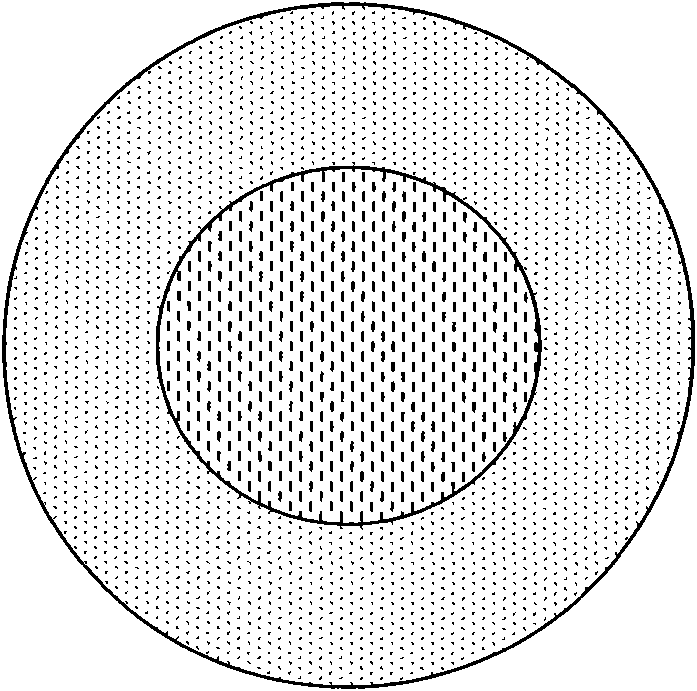

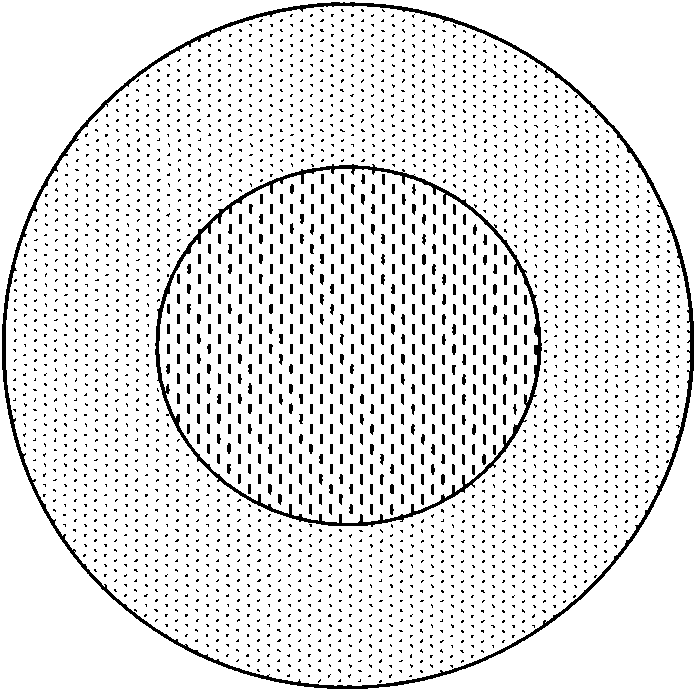

[0017] See attached figure 1 , a polyolefin composite fiber, made by sheath-core composite melt spinning process, the fineness is 5.0dtex, the cross section is circular, skin-core structure, the skin layer is made of polypropylene containing nano-pearl powder, and the attapulgite is used as the skin layer The polypropylene of the soil is the core layer, the mass ratio of the cortex to the core layer is 45:55, the quality of the nano pearl powder accounts for 10% of the mass of the cortex, and the mass of the attapulgite accounts for 10% of the mass of the core layer.

Embodiment 2

[0019] See attached figure 1 , a polyolefin composite fiber, made by sheath-core composite melt-spinning process, with a fineness of 4.0dtex, a circular cross-section, and a skin-core structure, with polyethylene containing nano-pearl powder as the skin layer, and attapulgite rods The polyethylene of the soil is the core layer, the mass ratio of the cortex to the core layer is 35:65, the quality of the nano-pearl powder accounts for 7% of the mass of the cortex, and the mass of attapulgite accounts for 8% of the mass of the core layer.

Embodiment 3

[0021] See attached figure 1 , a polyolefin composite fiber, made by sheath-core composite melt-spinning process, with a fineness of 2.0dtex, a circular cross-section, and a skin-core structure, with polypropylene containing nano-pearl powder as the skin layer, and attapulgite rods The polypropylene of the soil is the core layer, the mass ratio of the cortex to the core layer is 50:50, the quality of nano pearl powder accounts for 7% of the mass of the cortex, and the mass of attapulgite accounts for 5% of the mass of the core layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com