Method for preparing hydrogen electrode composite powder of solid oxide electrolyzer

A technology of solid oxide and composite powder, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems that the quality of NiO and YSZ is not easy to be accurately controlled, the particle size distribution of precipitated particles is wide, and the speed of precipitation formation is fast. Accurate metering ratio, good adhesion and strong catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

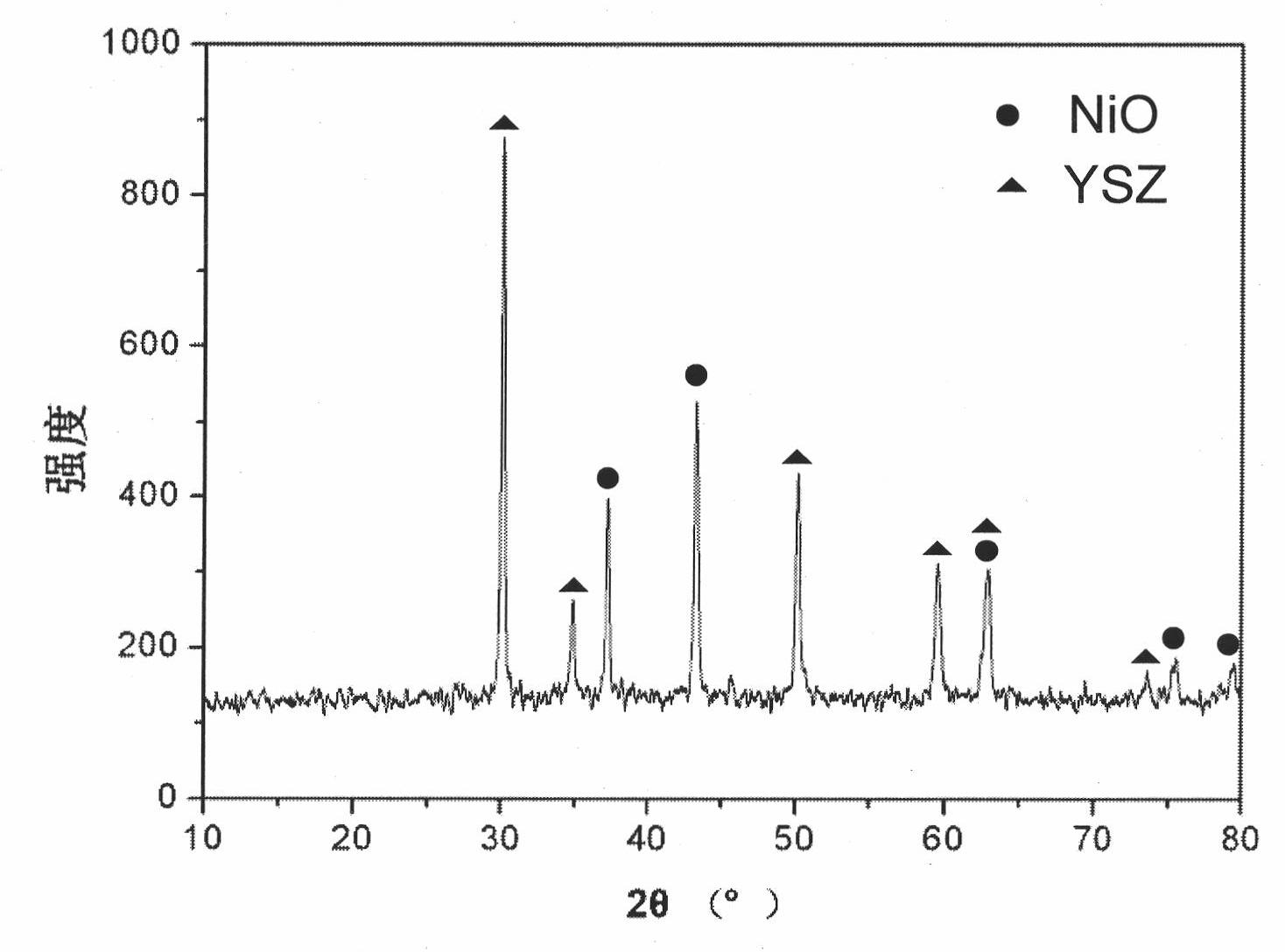

[0018] The present invention proposes a method for preparing a hydrogen electrode composite powder of a solid oxide electrolytic cell. In the method, YSZ powder is used as the core of the composite powder, NiO is used as a coating layer, and urea is used as a precipitant and a combustion aid in the preparation process. NiO was deposited on YSZ particles through two-step reactions of uniform precipitation and low-temperature self-combustion. The specific steps are as follows:

[0019] (1) Prepare 0.2~1.0mol / L nickel nitrate solution, then add required amount of urea and YSZ powder to the nickel nitrate solution, wherein the molar ratio of urea and nickel nitrate is 1.6:1~4:1, the mass of YSZ The ratio of the theoretical mass to the generated NiO is 0.8:1 to 2:1, and the prepared mixture is ultrasonically treated for 5 to 30 minutes;

[0020] (2) React for 1 to 10 hours in a water bath at 80 to 100°C under rapid stirring conditions to hydrolyze part of the urea, precipitate nick...

Embodiment 1

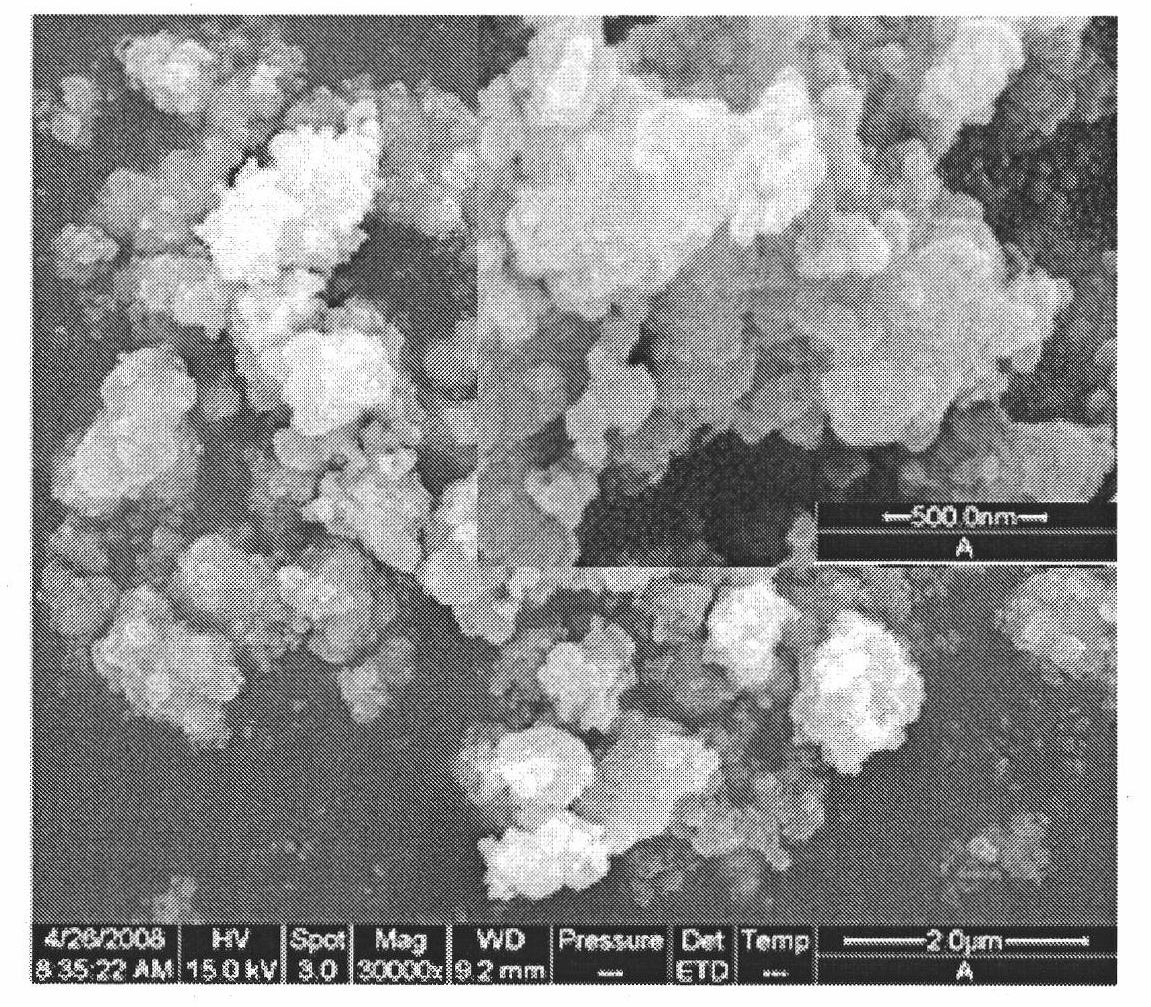

[0026] Ni(NO 3 ) 2 ·6H 2 O is dissolved in deionized water and is mixed with 0.5mol / L nickel nitrate solution, then adds required amount of urea and YSZ powder in the nickel nitrate solution, wherein the mol ratio of urea and nickel nitrate is 2: 1, the quality of YSZ and The ratio of the theoretical mass of the generated NiO is 1:1, and the prepared mixture is ultrasonically treated for 15 minutes to open the agglomeration between the YSZ powder particles and make them uniformly dispersed in the solution, as Ni(OH) 2 Precipitated core. Under the conditions of 90° C. water bath and rapid stirring, react for 4 hours to hydrolyze a part of urea, and precipitate nickel ions in the solution on the YSZ particles. Then transfer the resulting mixture to a ceramic round evaporating dish, and stir continuously while heating and evaporating until the suspension becomes a jelly, and continue heating until combustion occurs to obtain the primary powder of NiO-YSZ, and then carry out th...

example 2

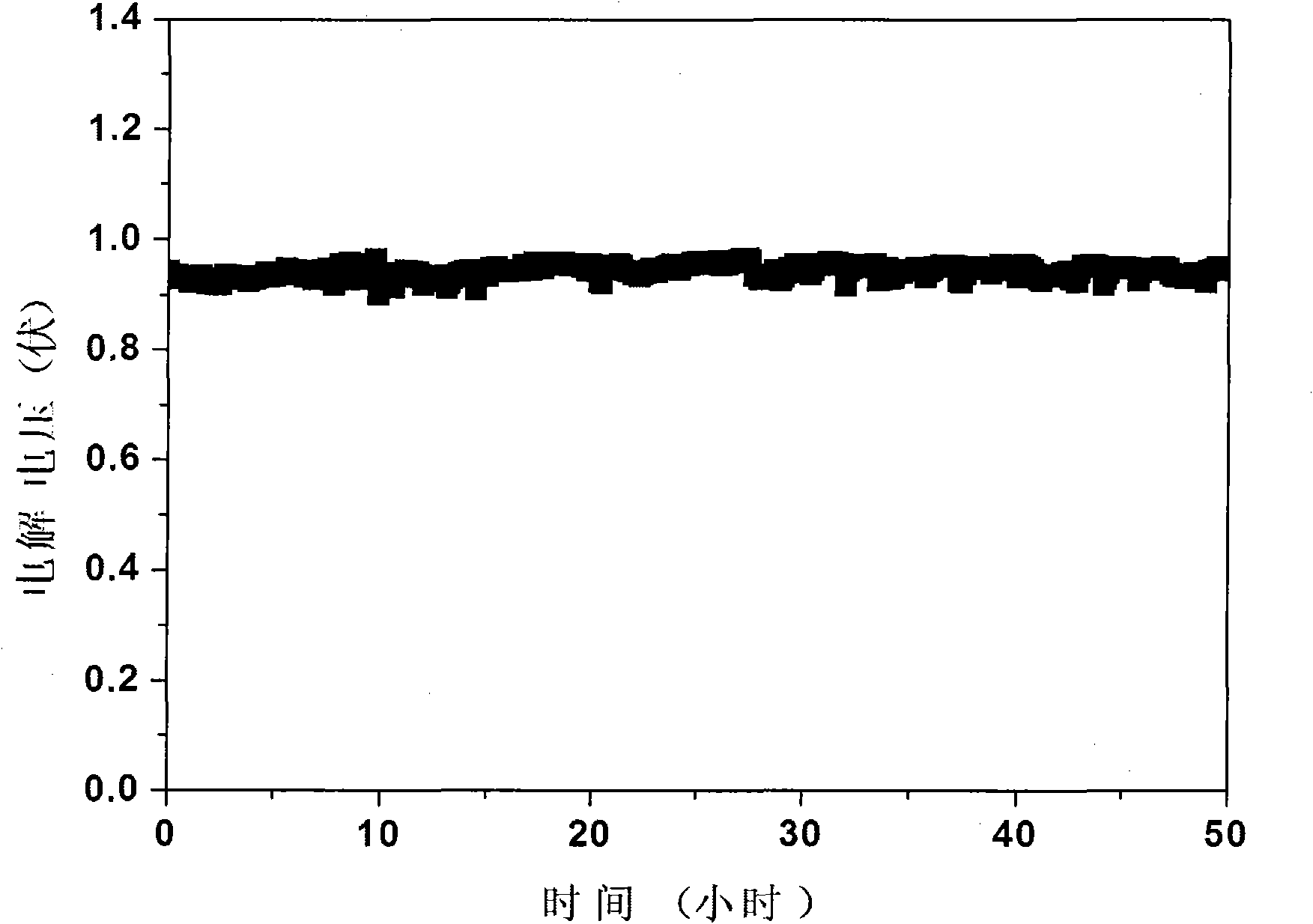

[0028] Example 2: Performance of Ni-YSZ / YSZ / YSZ-LSM electrolytic cell

[0029]The hydrogen electrode of Ni-YSZ / YSZ / YSZ-LSM electrolytic cell was prepared by dry pressing method. The diameter of the hydrogen electrode sheet is 17mm, the thickness is 0.5mm, and the sheet forming pressure is 250MPa. The mass ratio of NiO and YSZ in the hydrogen electrode is 1:1. In order to make the hydrogen electrode have sufficient pores to conduct gas, NiO and 25% starch of the total mass of YSZ were added as pore-forming agents. YSZ electrolyte and YSZ-LSM oxygen electrode were prepared by screen printing method, and the mass ratio of powder and organic binder in the screen printing paste was 1:2. The organic binder is formed by mixing 5wt% ethyl cellulose and 95wt% terpineol. The sintering temperature of the YSZ electrolyte is 1400 °C and the thickness is 15 μm. The calcination temperature of YSZ-LSM oxygen electrode is 1150℃, and the thickness is 50μm. image 3 For the prepared Ni-YSZ / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com