Process for extracting walnut oil from large walnut kernels through supercritical extraction

A process method, walnut kernel technology, applied in the direction of edible oil/fat, fat oil/fat production, fat production, etc., can solve the problems of greasy food taste, inability to form specific products, low efficiency and yield, etc., to reduce greasy feeling , good market prospects and development value, the effect of simple process and equipment flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Option One

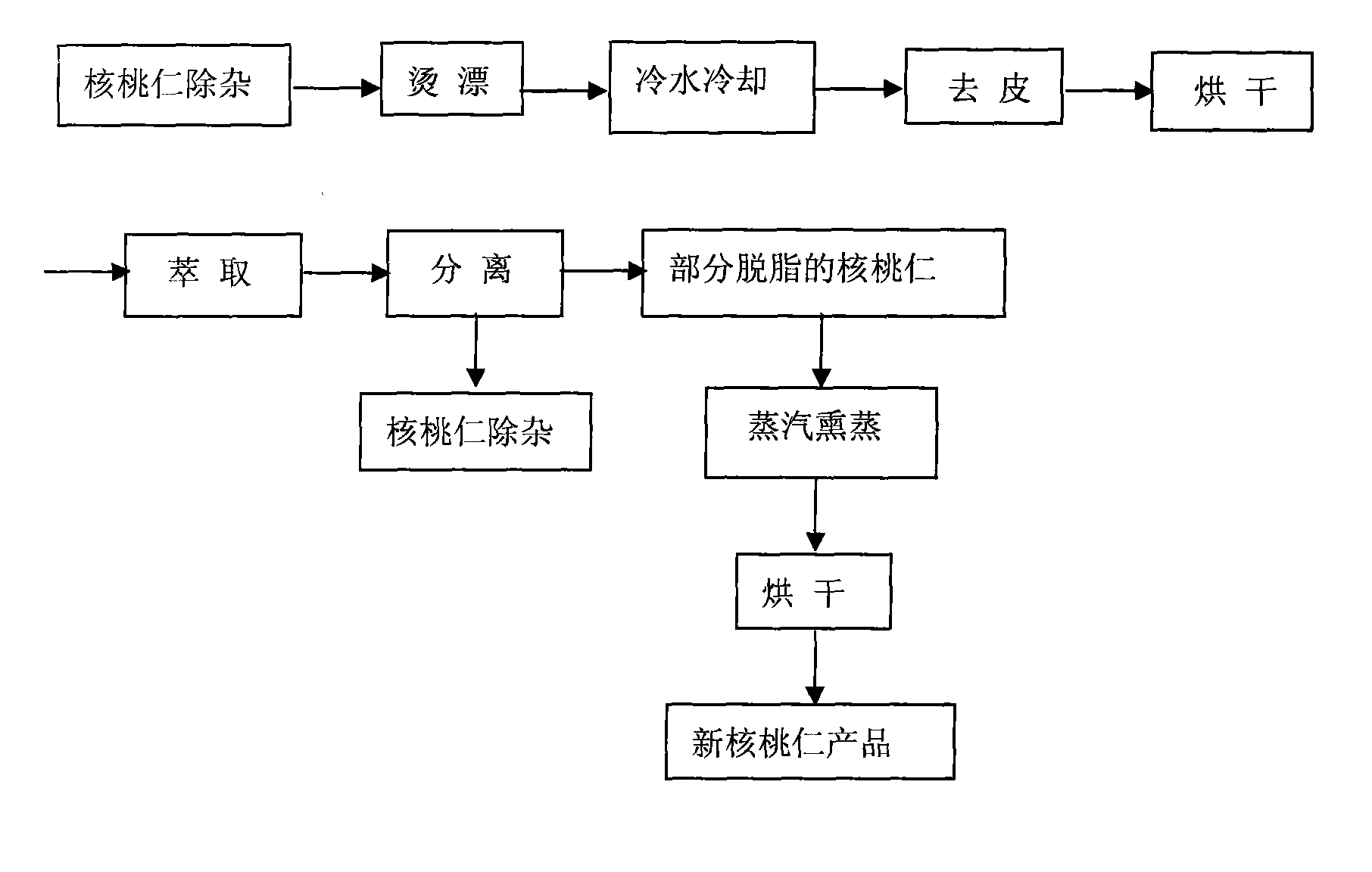

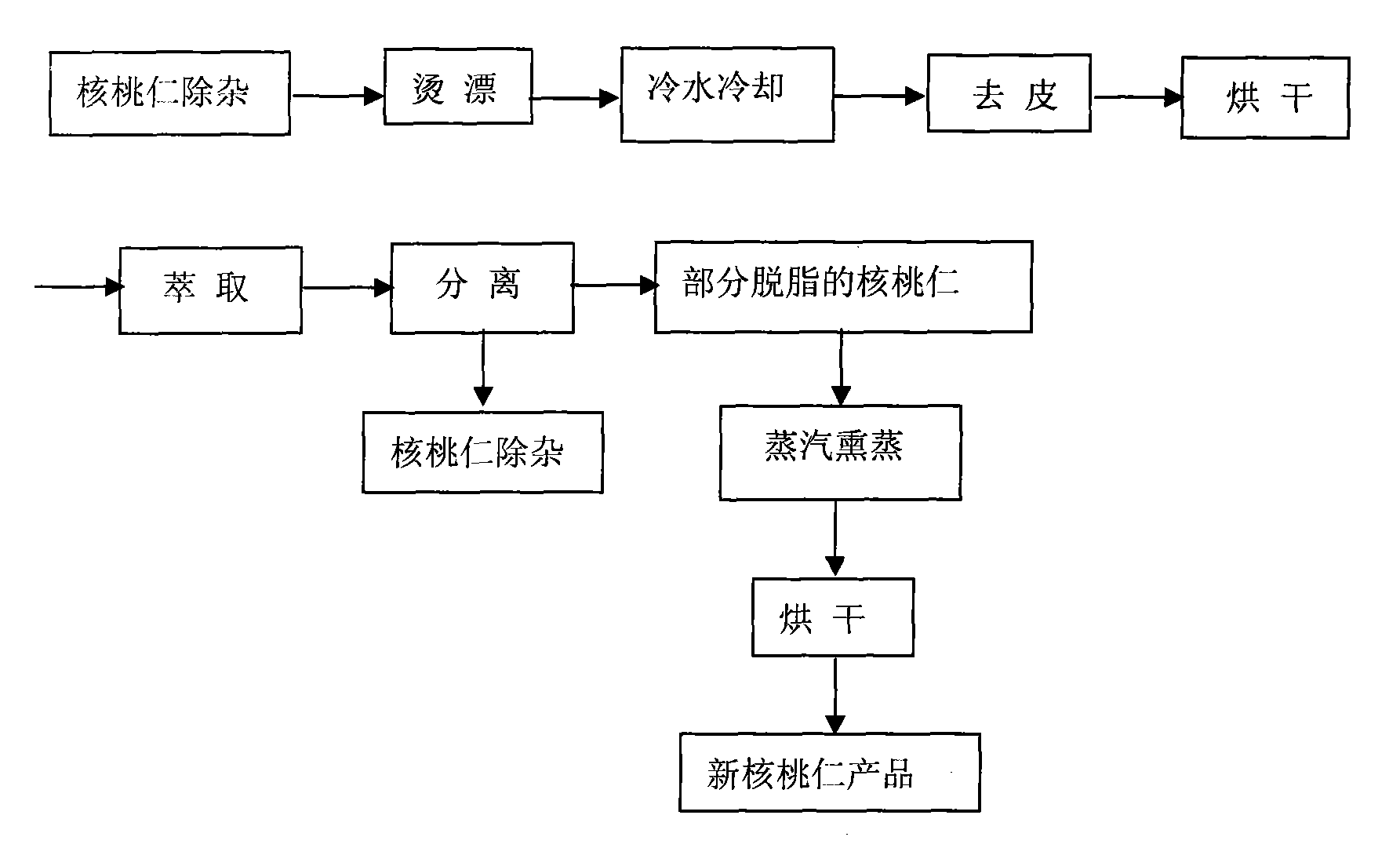

[0022] as attached figure 1 Shown, technological process of the present invention is:

[0023] Walnut kernel removal → blanching → cooling in cold water → peeling → drying → extraction →

[0024] Separation→partially defatted walnut kernels→steam fumigation→drying→new walnut kernel products

[0025] ↓

[0026] Walnut oil products.

[0027] The specific process method and technical parameters are as follows:

[0028] First, weigh 1,000 grams of selected walnut kernels, wash them, put them into hot water at 90°C for 2 minutes, quickly remove them into cold water, rinse them 2-3 times, cool them thoroughly, control them to dry, peel them, and then Dry at 40-45°C for 2 hours.

[0029] Put the dried walnut kernels into the extraction equipment for extraction. The extraction parameters are: the pressure of the extraction equipment is 30MPa, the temperature is 45°C; pressure, the pressure is gradually reduced to normal pressure during the pressure relief pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com