Succinyl-chitosan/polyvinyl alcohol composite sponge and preparation method thereof

A technology of carboxybutyryl chitosan and polyvinyl alcohol, applied in the field of carboxybutyryl chitosan/polyvinyl alcohol composite sponge and its preparation, to achieve good biocompatibility, promote immune mechanism reconstruction, and good biocombination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of carboxybutyryl chitosan / polyvinyl alcohol composite sponge comprises the steps:

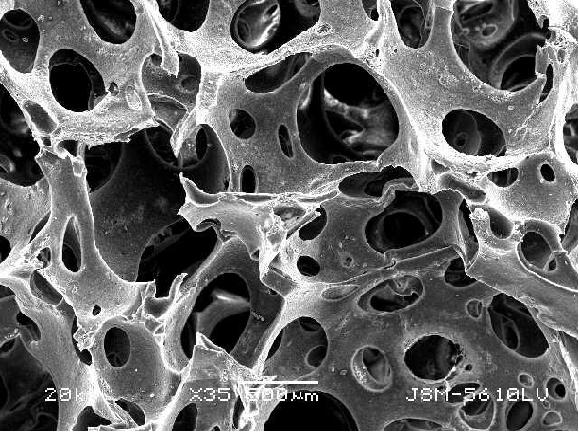

[0026] Polyvinyl alcohol and carboxybutyryl chitosan are according to the percentage by weight of each raw material: polyvinyl alcohol 10wt% with a degree of polymerization of 2000, carboxybutyryl chitosan 1wt%, water 65wt%, add in the there-necked bottle, in After condensing and refluxing at 100°C for 100 minutes, pour the solution into a beaker, add 9wt% sulfuric acid, 12wt% formaldehyde and 3wt% sodium bicarbonate, stir and mix evenly, pour the blend into a mold, and heat it in an oven at 60°C After molding for 8 hours, the carboxybutyryl chitosan / polyvinyl alcohol composite sponge was obtained. The resulting carboxybutyryl chitosan / polyvinyl alcohol composite sponge had an elongation at break of 327% and a water absorption rate of 1561%. The pore structure of the resulting carboxybutyryl chitosan / polyvinyl alcohol composite sponge is shown in figure 2 . f...

Embodiment 2

[0028] The preparation method of carboxybutyryl chitosan / polyvinyl alcohol composite sponge comprises the steps:

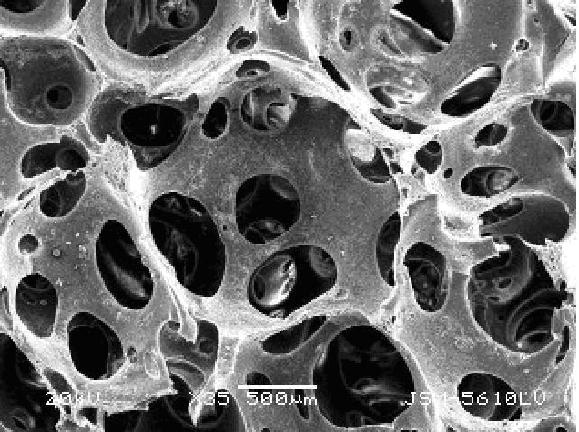

[0029] Put polyvinyl alcohol and carboxybutyryl chitosan according to the percentage by weight of each raw material: 10wt% of polyvinyl alcohol with a degree of polymerization of 2000, 1.5wt% of carboxybutyryl chitosan, and 64.5wt% of water, and add them to the three-necked bottle , After condensing and refluxing at 100°C for 100 minutes, pour the solution into a beaker and add 9wt% sulfuric acid, 12wt% formaldehyde and 3wt% sodium bicarbonate, stir and mix evenly, pour the blend into a mold, and place in an oven for 60 ℃ thermoforming for 8 hours to obtain carboxybutyryl chitosan / polyvinyl alcohol composite sponge. The resulting carboxybutyryl chitosan / polyvinyl alcohol composite sponge had an elongation at break of 379% and a water absorption rate of 1532%. The pore structure of the resulting carboxybutyryl chitosan / polyvinyl alcohol composite sponge is shown i...

Embodiment 3

[0031] The preparation method of carboxybutyryl chitosan / polyvinyl alcohol sponge comprises the steps:

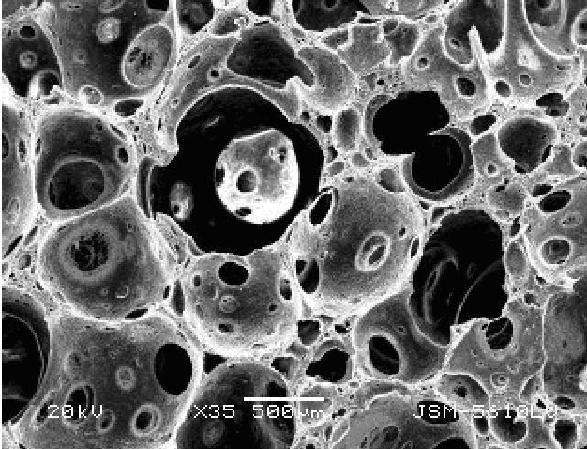

[0032] Polyvinyl alcohol and carboxybutyryl chitosan are according to the percentage by weight of each raw material: polyvinyl alcohol 10wt% that the degree of polymerization is 2000, carboxybutyryl chitosan 2wt%, water 64wt%, add in the there-necked bottle, in After condensing and refluxing at 100°C for 100 minutes, pour the solution into a beaker, add 9wt% sulfuric acid, 12wt% formaldehyde and 3wt% sodium bicarbonate, stir and mix evenly, pour the blend into a mold, and heat it in an oven at 60°C After molding for 8 hours, the carboxybutyryl chitosan / polyvinyl alcohol composite sponge was obtained. The resulting carboxybutyryl chitosan / polyvinyl alcohol composite sponge had an elongation at break of 335% and a water absorption rate of 1468%. The pore structure of the resulting carboxybutyryl chitosan / polyvinyl alcohol composite sponge is shown in Figure 4 . Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com