Medical efficient bacterium blocking filter material and preparation method thereof

A filter material and high-efficiency technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as complicated procedures, increased risk of cross-infection of bacteria by medical staff, and poor barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

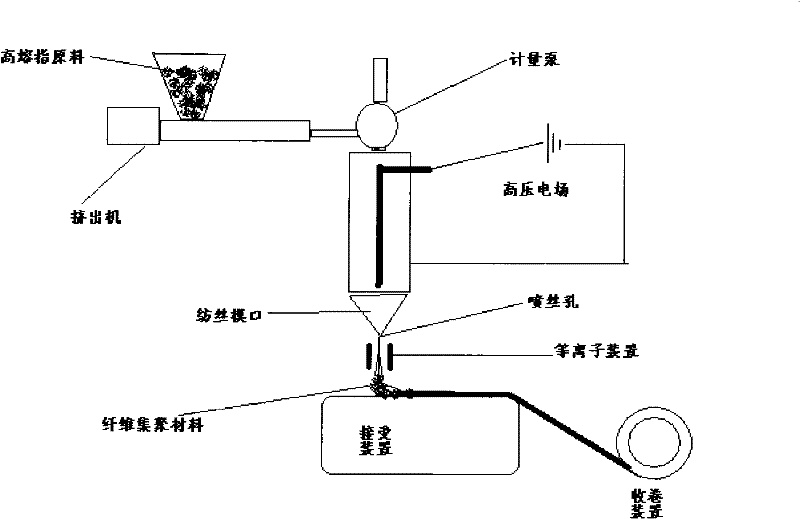

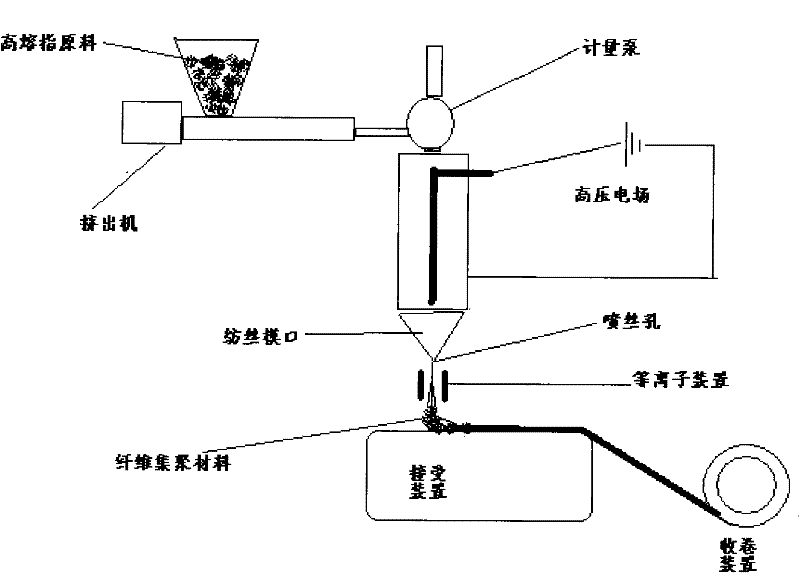

[0023] The melted polyolefin polymer particles with a high melt index of 800 are continuously transported to a spinning die through a metering pump under the action of a continuous DC high-voltage electric field. The electric field voltage is 100kv, and the spinning die is a In the linear direction, there are spinneret holes linearly arranged at an interval of 0.3 mm, the diameter of the spinneret holes is 0.25 mm, and the lateral length of the spinneret die opening is greater than 20 cm. There is a low pressure at 3 cm from the outlet of the spinneret die

[0024] Plasma emission device, when the fiber ejected by the melt from the die mouth is plasma-treated, it falls on the collection device at a distance of 20 cm from the spinning die mouth and cools down and then takes shape in the winding device. Quantitative at 20g / m 2 .

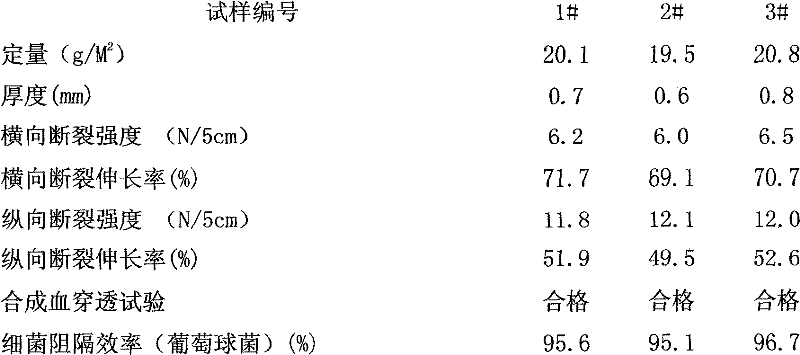

[0025] Test its barrier performance as follows:

[0026]

Embodiment 2

[0028] The melted polyolefin polymer particles with a high melt index of 800 are continuously transported to a spinning die through a metering pump under the action of a continuous DC high-voltage electric field. The electric field voltage is 100kv. In the linear direction, there are spinneret holes linearly arranged at an interval of 0.3 mm, the diameter of the spinneret holes is 0.25 mm, and the lateral length of the spinneret die opening is greater than 20 cm. There is a low-pressure plasma emission device at a distance of 3 cm from the exit of the spinning die. When the fibers ejected from the die are treated with plasma, they fall on the collecting device at a distance of 20 cm from the spinning die and cool down. Formed in the winding device. Quantitative at 25g / m 2 .

[0029] Test its barrier performance as follows:

[0030]

Embodiment 3

[0032] The molten polyolefin polymer particles with a high melt index of 800 are continuously transported to a spinning die through a metering pump under the action of a continuous DC high-voltage electric field. The electric field voltage is 100kv, and the spinning die is equipped with There is a spinneret hole linearly arranged at an interval of 0.3 mm, the diameter of the spinneret hole is 0.25 mm, and the lateral length of the spinneret die is greater than 20 cm. There is a low-pressure plasma emission device at a distance of 3 cm from the exit of the spinning die. When the fibers ejected from the die are treated with plasma, they fall on the collecting device at a distance of 20 cm from the spinning die and cool down. Formed in the winding device. Quantitative at 28g / m 2 .

[0033] Test its barrier performance as follows:

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com