Programmable nanosecond double-pulse integrated power supply

An integrated power supply and double-pulse technology, which is applied in the field of power supply and micro-processing, can solve the problems of single function and limited parameter adjustment range, and achieve the effect of high pulse frequency, convenient parameter setting and easy computer control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

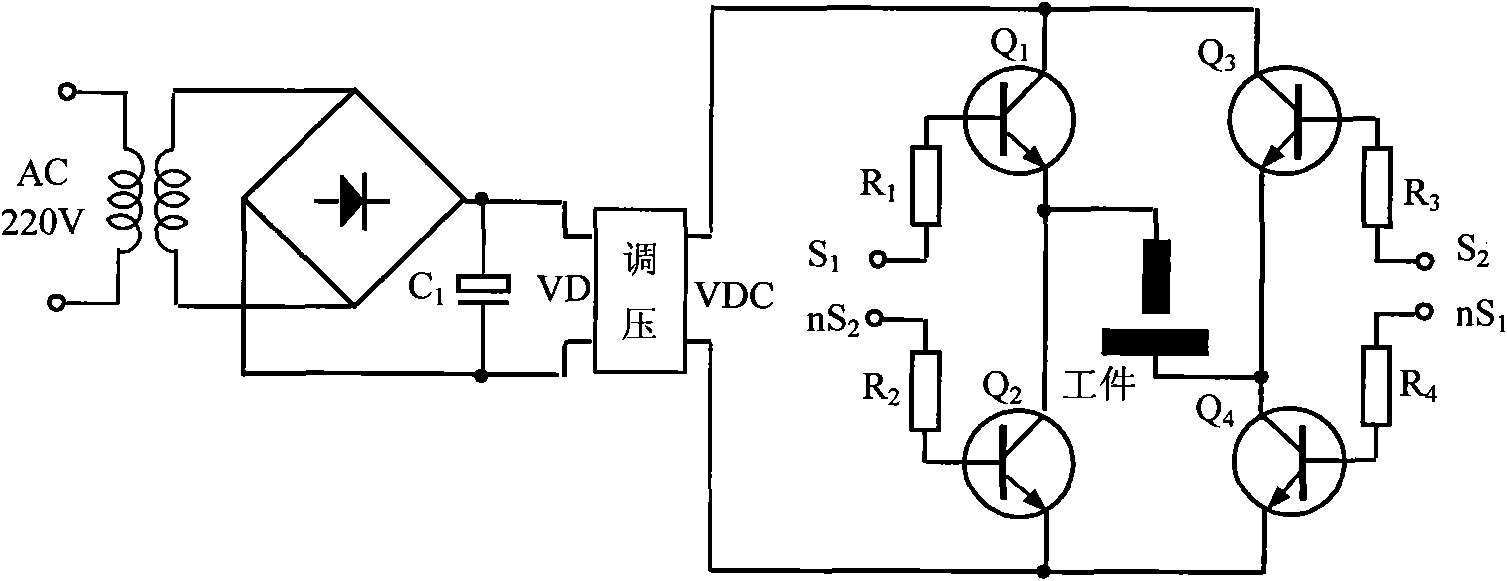

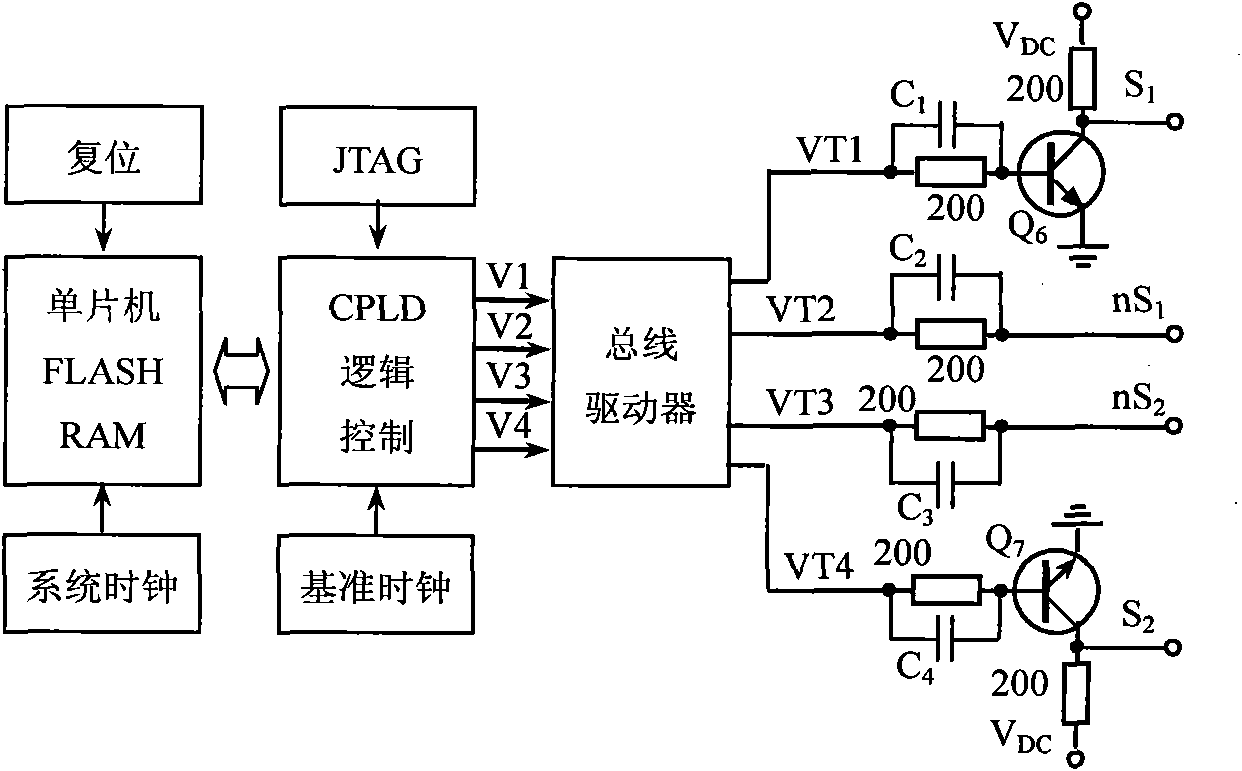

[0034] The technical solution will be further described below in conjunction with the accompanying drawings and specific embodiments (in this example, the switching tube Q 1 ~Q 4 It is a high-speed switching tube. ):

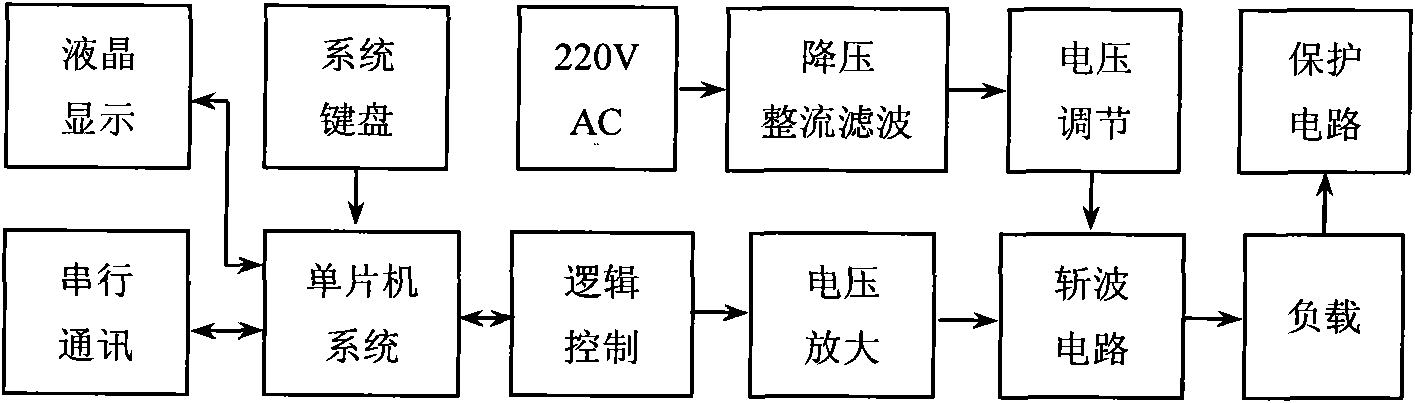

[0035] 1. Working principle and overall structure

[0036] 1.1 Working principle

[0037] The main circuit structure of the double-pulse nanosecond power supply is as follows: figure 1 shown. In the circuit shown in the figure, the 220V power frequency alternating current is first step-down and transformed, and then enters the full-bridge rectification and capacitor filter circuit to obtain the DC voltage required for processing.

[0038] Control voltage S 1 , nS 1 For high voltage, S 2 , nS 2 is zero voltage, the switching tube Q 1 , Q 4 Saturated conduction, Q 2 , Q 3 cut-off, the current through Q 1 Flows from the tool electrode to the workpiece, and then passes through Q 4 To the cathode of the power supply, the tool electrode is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com