Nanostructured thermoelectric material and device and production method thereof

A thermoelectric material and nanostructure technology, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device parts and other directions, can solve the problems of poor thermal stability and difficult deviceization, and achieve the effect of improving performance and crystallinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

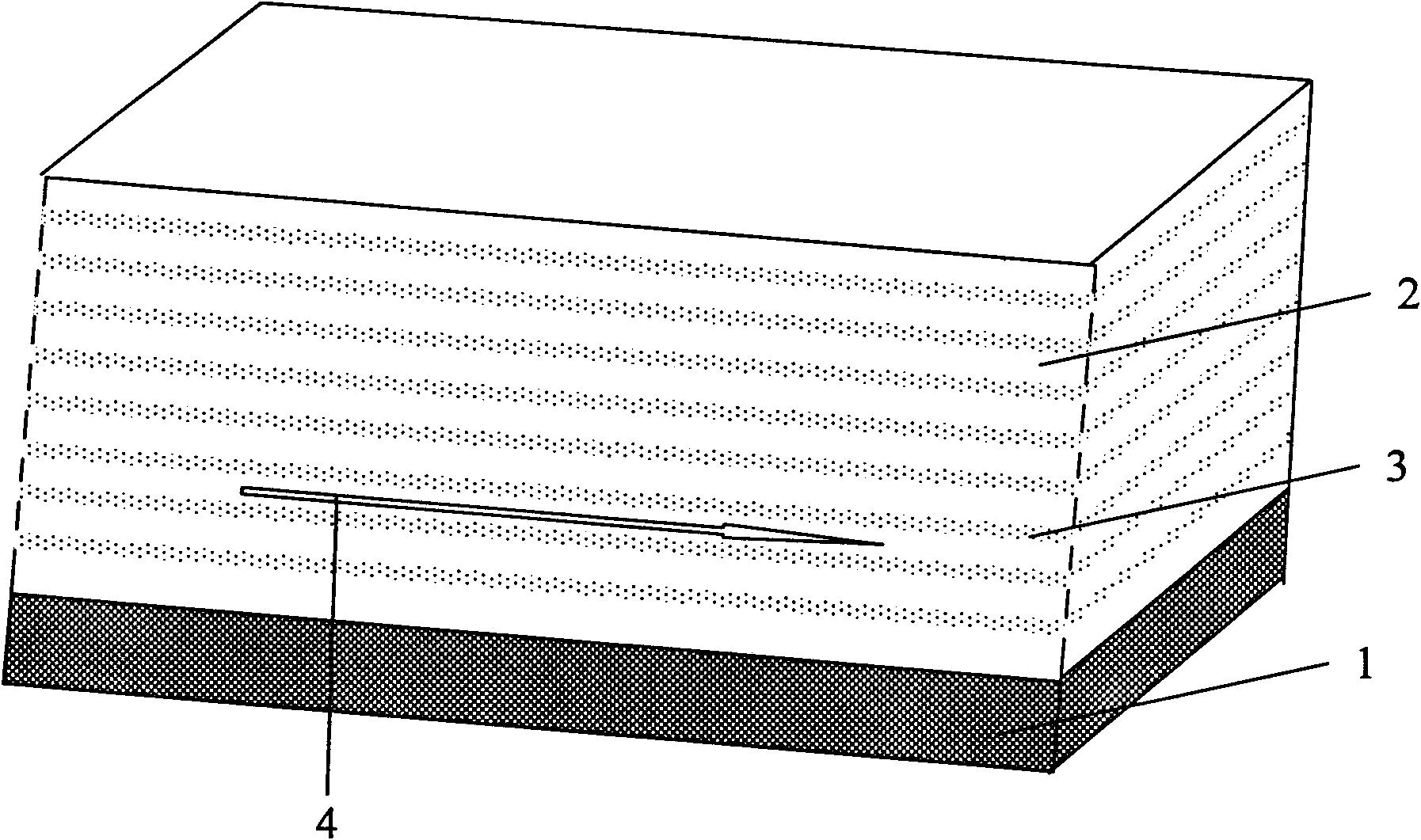

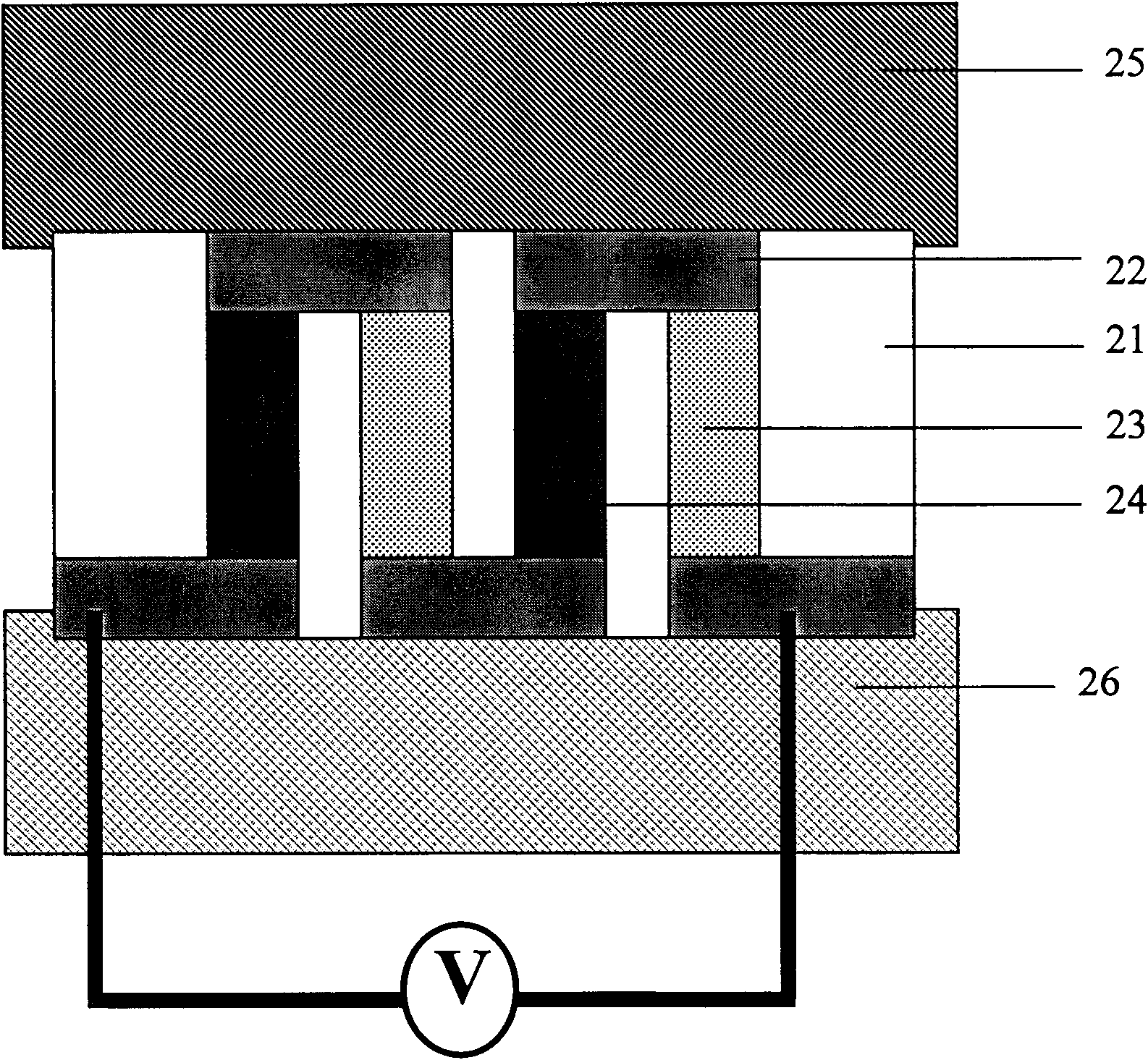

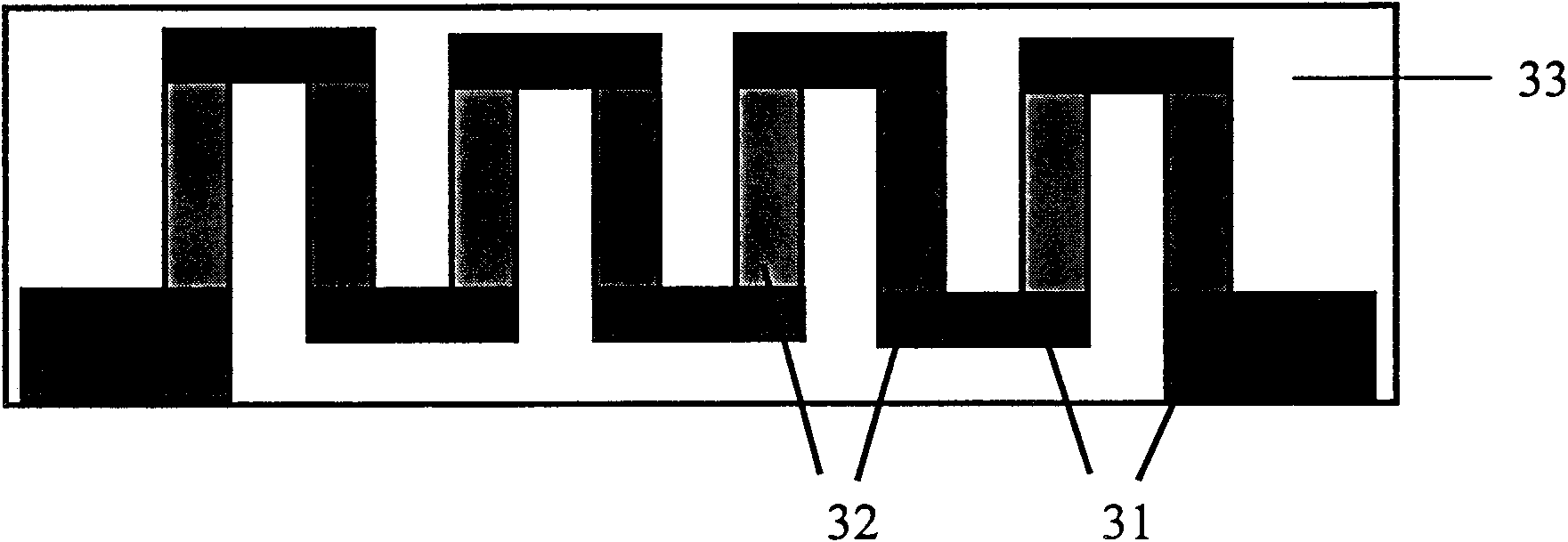

[0049] Thermoelectric multilayer devices deposited using masked magnetron sputtering:

[0050] In this example, glass is used as the substrate, the bismuth-tellurium thermoelectric material is used as the thermoelectric layer, and the tungsten particle accumulation interface is used as the phonon scattering layer. The film deposition method is radio frequency magnetron sputtering, and the background vacuum is 1*10 -4 Pa, the working pressure is 0.7Pa.

[0051] The glass substrate was cleaned ultrasonically with acetone, alcohol and deionized water in sequence, and the substrate was blown dry with dry pure nitrogen.

[0052] Cover the p-type thermoelectric arm mask on the substrate. Use radio frequency magnetron sputtering to coat a layer of p-type thermoelectric material with a power density of 1-10W / cm 2 , the thickness is 10nm, and then coated with a layer of tungsten particles, the power density can be 1~5W / cm 2 , the particle size is 5nm, the interface thickness is 5nm...

Embodiment 2

[0057] Thermoelectric multilayer devices deposited using masked magnetron sputtering:

[0058] The mica is used as the substrate, the bismuth-tellurium series thermoelectric material is used as the thermoelectric layer, and the silicon dioxide particle accumulation interface is used as the phonon scattering layer. The film deposition method is radio frequency magnetron sputtering, and the background vacuum is 1*10 -4 Pa, the working pressure is 0.1-2Pa.

[0059] The mica substrate was ultrasonically cleaned with acetone, alcohol, and deionized water in sequence, and the substrate was blown dry with dry pure nitrogen.

[0060] Cover the p-type thermoelectric arm mask on the substrate. Use radio frequency magnetron sputtering to coat a layer of p-type thermoelectric material with a power density of 2W / cm 2 , the thickness is 100nm, and then coated with a layer of silica particles, the power density is 2W / cm 2 , the particle size is 5nm, the interface thickness is 5nm, this pro...

Embodiment 3

[0065] Thermoelectric multilayer devices deposited using masked magnetron sputtering:

[0066] In this example, mica is used as the substrate, the cobalt-antimony series thermoelectric material is used as the thermoelectric layer, and the tungsten particle accumulation interface is used as the phonon scattering layer. The film deposition method is radio frequency magnetron sputtering, and the background vacuum is 1*10 -4 Pa, the working pressure is 0.1-2Pa.

[0067] The mica substrate was ultrasonically cleaned with acetone, alcohol, and pure water in sequence, and the substrate was blown dry with dry pure nitrogen.

[0068] Cover the p-type thermoelectric arm mask on the substrate. Use radio frequency magnetron sputtering to coat a layer of p-type thermoelectric material with a power density of 0.1W / cm 2 , the thickness is 5nm, and then coated with a layer of tungsten particles, the power density is 0.1W / cm 2 , the particle size is 1nm, the interface thickness is 1nm, thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com