An electrolytic polishing process

An electrolytic polishing and process technology, applied in the field of electrolytic polishing process and polishing process, can solve the problem that pressure vessel standards and specifications cannot fully meet the requirements of process conditions, and achieve the effect of short polishing time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

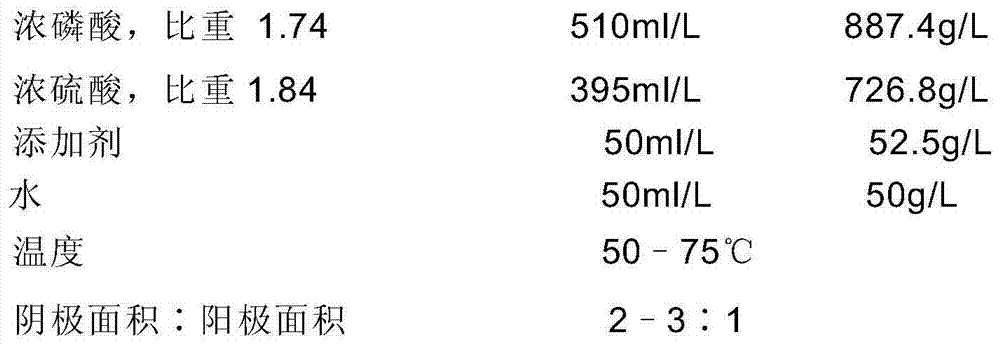

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1. The surface roughness of the plate can reach about Ra=0.05 μm and electrolytic polishing.

[0065]Generally, the precision achieved for electrolytic polishing is around Ra0.1. According to the characteristics of electrolytic polishing, in order to achieve a surface finish of Ra<0.1μm, the steps that can be achieved by combining mechanical polishing and electrolytic polishing are as follows: First, use conventional methods to obtain an electrolytic polished surface with Ra=0.1μm or so; Then use mechanical polishing or grinding to obtain a surface of Ra=0.03μm, and finally use electrolysis within a specified time range to obtain an electropolished surface with a roughness of about Ra=0.05μm.

Embodiment 2

[0066] Embodiment 2, compound polishing of heat exchange tube

[0067] Composite polishing of heat exchange tubes: The mechanical polishing of the inner surface of heat exchange tubes that can be achieved in the market (diameter <60mm, length greater than 1500mm) can only reach about Ra0.6. Because the polishing method currently on the market is difficult to use force during polishing, it is almost difficult to pass the sampling inspection of broken pipes in the middle of the pipe. For this reason, this equipment adopts special tooling to fine-polish the purchased (rolled surface reaches about Ra0.4) stainless steel cold-rolled and fine-rolled bright tubes to about Ra0.2. Then electrolytic polishing is used to electrolyze the heat exchange tube of Ra0.3 to about Ra0.1.

Embodiment 3

[0068] Example 3. Composite polishing of flower plate holes

[0069] Composite polishing of flower plate holes: Since the diameter of the holes is only 9mm and the number is very large. Therefore, electrolytic polishing is used to electrolyze the inner surface of the finely reamed flower plate hole Ra0.4 to about Ra0.1. In the second step, the holes with serious surface machining traces are mechanically polished and ground with a custom-made nylon polishing head containing quartz. The third step is to mechanically polish the surface and outer circle of the flower plate to about Ra0.3. Finally, the overall electrolytic polishing is carried out. Note: Sometimes it is necessary to repeat between the first step and the second step until the inner hole finish reaches 0.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com