Multi-head fully-automatic feed tapping machine

A fully automatic, tapping machine technology, used in thread trimmers, metal processing equipment, thread trimming devices, etc., can solve the problems of low production efficiency, high material consumption, high energy consumption, etc., so as to reduce the occupied space and improve the Production efficiency, the effect of reducing consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

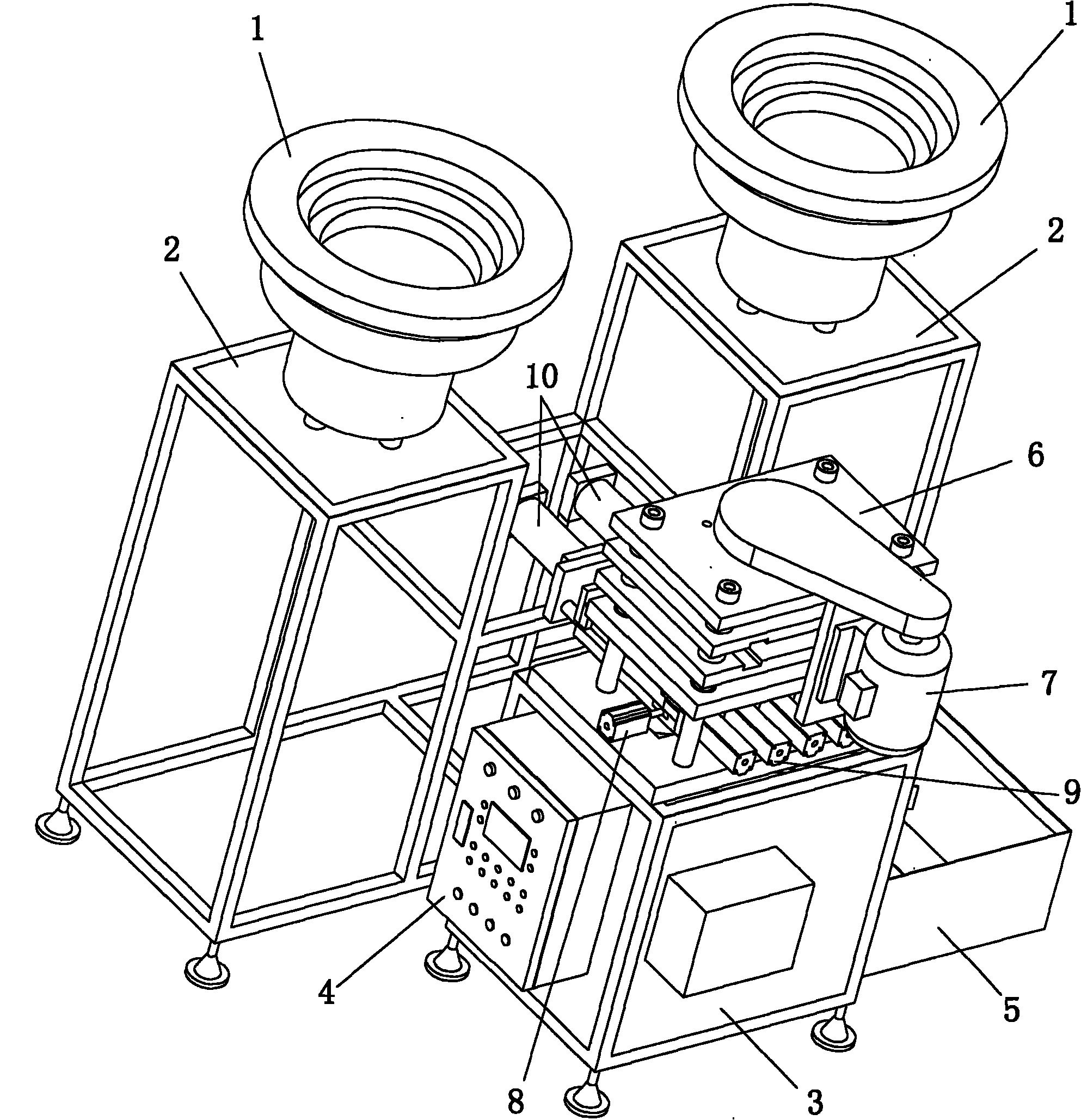

[0015] In this example, refer to figure 1 , figure 2 , image 3 with Figure 4 , the multi-head automatic feeding tapping machine includes a feeding part, a tapping part and a control part; the feeding part includes a feeding tray frame 2, a feeding vibration plate 1 is installed on the feeding plate frame 2, and a feeding vibration plate 1 is provided with The feeding pipe 14; the feeding vibrating plate 1 includes a vibrating host 11, the vibrating host 11 is installed on the feeding tray frame 2, a rotatable vibrating inner disc 12 is installed on the vibrating host 11, and a rotatable vortex is provided on the inner wall of the vibrating inner disc 12 Shaped product distribution plate 13, the starting end of the feed pipe 14 passes through the wall of the vibrating inner disk 12 and docks with the product distribution plate 13; the tapping part includes the main frame 3, the cooling oil tank 5, the tapping mechanism 6 and the motor 7, the tapping The threading mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com