Low-cost and high-toughness X80 pipe steel with high deformation resistance and manufacture method thereof

A technology of anti-large deformation and production method, which is applied in the field of metal material rolling, can solve the problems of inability to produce hot-rolled steel plates with specifications above 22mm, narrow temperature control range of production process, and increase the difficulty of production control, and achieve excellent comprehensive mechanics. performance, improved resistance to large deformations, and the effect of reducing the critical cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

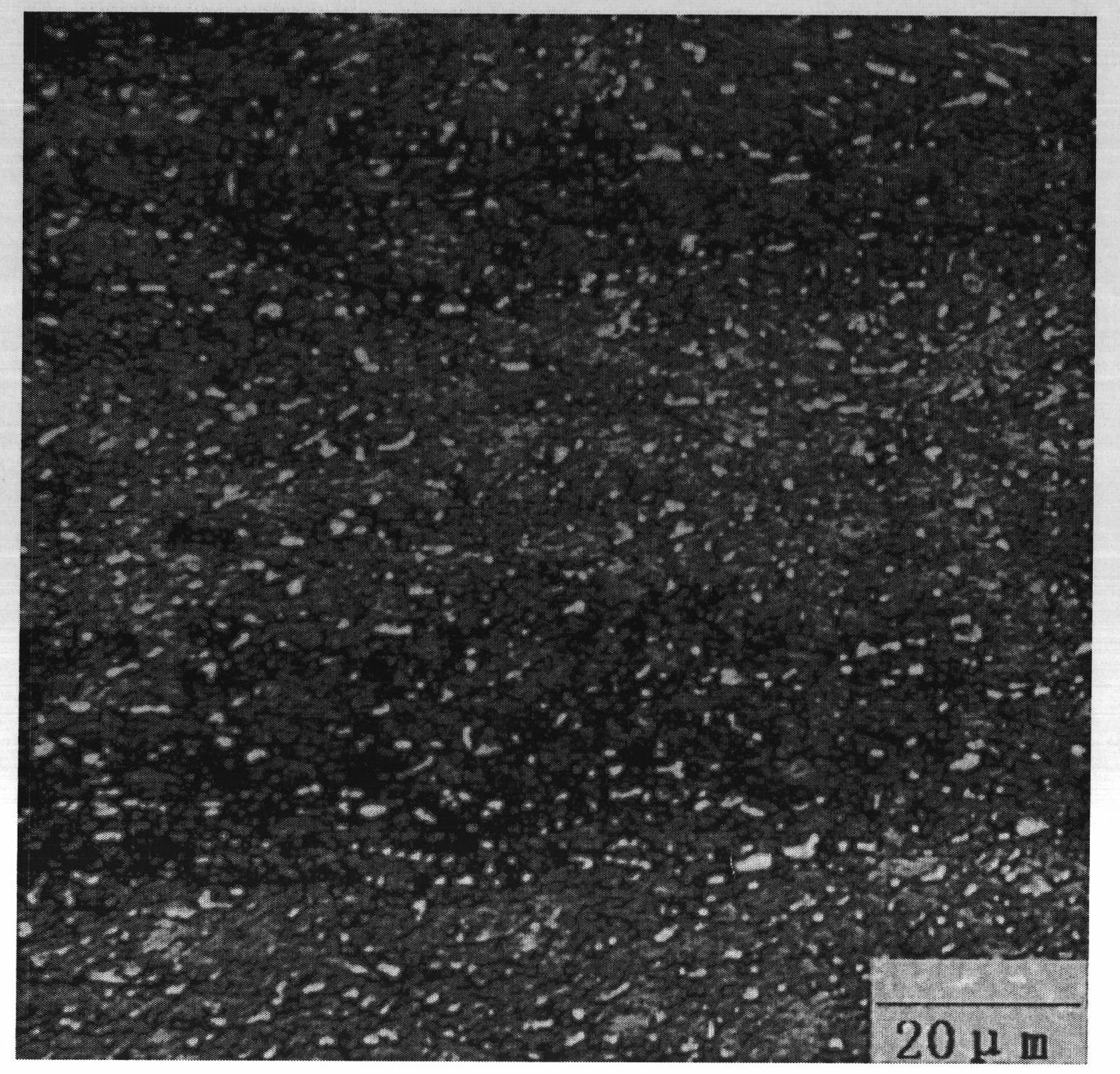

Image

Examples

Embodiment 1

[0029] The chemical composition (wt%) of the developed X80 grade anti-large deformation pipeline steel is: C accounts for 0.052, Si accounts for 0.24, Mn accounts for 1.77, Nb accounts for 0.074, Ti accounts for 0.015, Mo accounts for 0.17, Ni accounts for 0.18, Cu accounts for 0.24 , P≤50ppm, S≤50ppm.

[0030] Send the cast slabs that meet the composition requirements to a soaking furnace at 1200°C. After holding the heat for 150 minutes, descale the cast slabs by high-pressure water to remove the iron oxide scales on the cast slabs, and then enter into two-stage rolling. The first stage of rolling is rolled in the recrystallization zone, the rolling start temperature is 1100°C, and the final rolling temperature is 1050°C; after multiple passes of rolling, the continuous casting slab is rolled to 81mm, and the reduction of each pass They are 18%, 20%, 22%, 22%, 24%, respectively, and the cumulative total reduction is 70%.

[0031] The intermediate billet is warmed to 900°C b...

Embodiment 2

[0035] The chemical composition (wt%) of the developed X80 grade anti-large deformation pipeline steel is: C accounts for 0.047, Si accounts for 0.15, Mn accounts for 1.71, Nb accounts for 0.038, Ti accounts for 0.008, Mo accounts for 0.21, Ni accounts for 0.25, Cu accounts for 0.22 , P≤50ppm, S≤50ppm.

[0036] Send the cast slabs that meet the composition requirements to a soaking furnace at 1200°C. After holding the heat for 150 minutes, descale the cast slabs by high-pressure water to remove the iron oxide scales on the cast slabs, and then enter into two-stage rolling. The first stage of rolling is rolled in the recrystallization zone, the rolling start temperature is 1100°C, and the final rolling temperature is 1050°C; after multiple passes of rolling, the continuous casting slab is rolled to 81mm, and the reduction of each pass They are 18%, 20%, 22%, 22%, 24%, respectively, and the cumulative total reduction is 70%.

[0037] The intermediate billet is warmed to 900°C b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com