Method for processing waste water containing heavy metals by utilizing internal electrolysis-electrolysis method

An electrolytic treatment and heavy metal technology, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Improved processing efficiency, reduced operating costs, and increased reaction rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

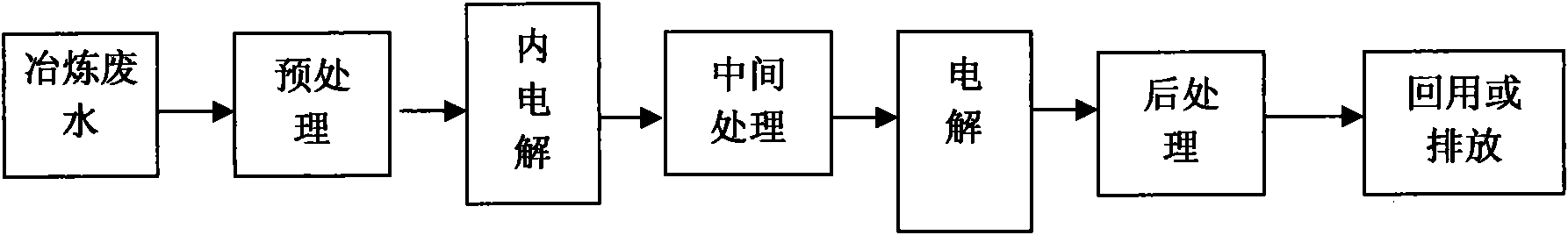

[0024] Embodiment 1: as figure 1It is the treatment process of the internal electrolysis-electrolysis treatment process scheme for the treatment of smelting wastewater. The acidic heavy metal-containing wastewater (pH: 2.11) in the smelting workshop is added with alkali (lime) to make the pH rise to 2.5, and the wastewater from the neutralization sedimentation tank enters the iron-carbon micro-electrolysis equipment with a hydraulic retention and aeration time of 30mi; then enters the sedimentation pool, the pH of the supernatant after self-flocculation reaches 5.5, in which a large amount of metal ions such as zinc, cadmium, arsenic, and lead are oxidized into metal atoms, a large amount of fluorine and other impurities are removed, and the supernatant directly enters the electrolysis device , the hydraulic retention time is 15min, the metal ions in the sewage are basically removed, and the sewage after electrolysis enters the sedimentation tank (the pH of the electrolysis wa...

Embodiment 2

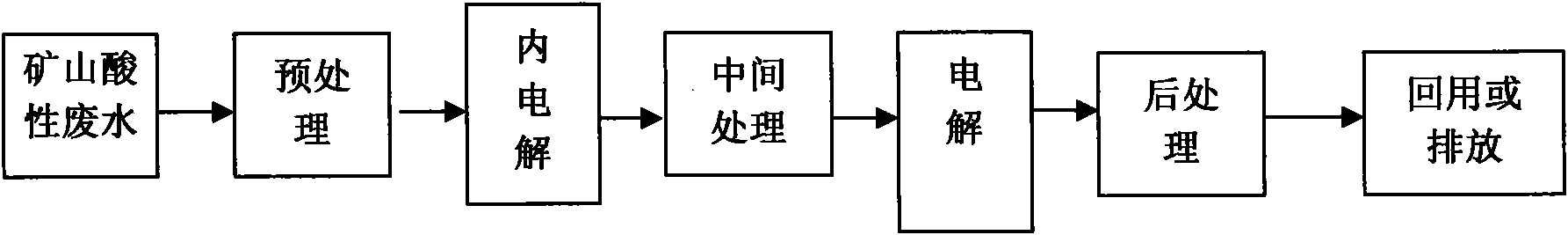

[0028] Embodiment 2: as figure 2 It is a treatment process for internal electrolysis_electrolysis to treat electroplating acid wastewater. Electroplating acid wastewater (PH: 2.6) is collected and precipitated by the sedimentation tank and directly enters the iron-carbon micro-electrolysis equipment. The hydraulic retention time is 30 minutes, and then enters the sedimentation tank. Metal ions such as zinc, chromium, nickel, cadmium, arsenic, and lead are oxidized into metal atoms, and a large amount of fluorine and other impurities are removed. The supernatant can directly enter the electrolysis device, and the hydraulic retention time is 15 minutes. The metal ions in the sewage are basically The above is removed, and the sewage after electrolysis enters the sedimentation tank (adding alkali appropriately to make the pH rise to 9, adding flocculant appropriately), and the metal ions in the supernatant can reach the third-class standard of surface water. The supernatant ente...

Embodiment 3

[0033] Embodiment 3: as figure 1 It is the treatment process of the internal electrolysis-electrolysis treatment process plan for the treatment of acidic wastewater in mines. Add alkali (lime) to the heavy metal-containing acidic wastewater (pH: 1.65) of mineral processing to make the pH rise to 2.5, and the wastewater from the neutralization and sedimentation tank enters the iron-carbon micro-electrolysis equipment, and the hydraulic retention and aeration time is 30 minutes; after that, it enters the sedimentation pool, the pH of the supernatant after self-flocculation reaches 5.3, in which a large amount of metal ions such as zinc, cadmium, arsenic, and lead are oxidized into metal atoms, a large amount of fluorine and other impurities are removed, and the supernatant directly enters the electrolysis device , the hydraulic retention time is 15min, the metal ions in the sewage are basically removed, and the sewage after electrolysis enters the sedimentation tank (the pH of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com