Method for high temperature wastewater treatment and reuse in MTO process

A technology of high-temperature wastewater and treatment methods, which is applied in natural water treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc. Use and other problems to achieve good effluent water quality, good effluent water quality, and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

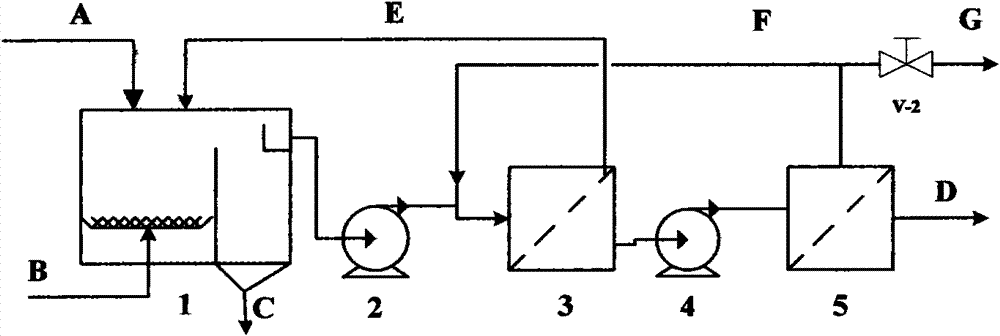

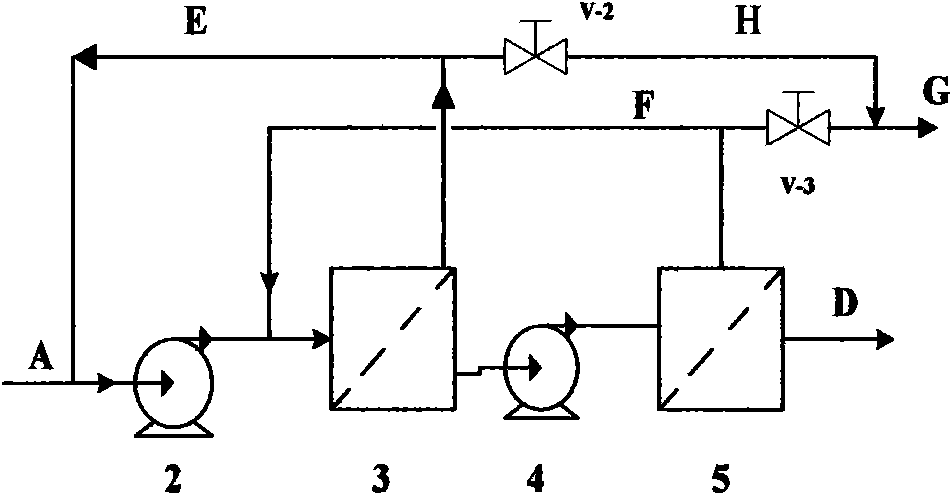

[0039] The high-temperature wastewater treatment process of the stripping tower kettle is as follows: figure 1 As shown, the 70°C MTO process stripping tower purified water A is discharged into the sedimentation separation tank 1, and the main water quality parameters include: the wastewater temperature is 70°C, the pH is 5.5, the turbidity is 86.9NTU, and the oil content is 8.9mg / L , the total iron content is 45.2mg / L, SiO 2 The content is 8.9μg / L.

[0040] Firstly, the stripped purified water is adjusted to pH 8.0, mixed by pipeline mixer, and discharged into sedimentation separation tank 1. At the bottom of the sedimentation separation tank, microporous aeration device B is used for aeration operation, and the aeration flow rate is 50L / min. The hydraulic residence time of alkali-adjusted aeration is 20 minutes, and the precipitated colloidal substances are discharged through the sludge discharge port C. The mixed wastewater after alkali-adjusted aeration is discharged into...

Embodiment 2

[0044] High temperature wastewater treatment process such as figure 1 As shown, the 80°C MTO process stripper purified water A is discharged into the sedimentation separation tank 1, wherein the quality of the stripper purified water is as described in Example 1, and the same pretreatment process in Example 1 is adopted. After pretreatment The process water quality is as described in Example 1.

[0045] The stripped purified water after pretreatment is sent to the ultrafiltration system 3 through the centrifugal pump 2. The pore size of the ultrafiltration membrane is 0.1 μm high-temperature resistant organic ultrafiltration membrane Duratherm HWS UF 2540, and the effective membrane area is 2.3m 2 , the ultrafiltration membrane filtration flux is 200L / m 2 h, the water supply pressure of the ultrafiltration membrane system is 0.2 bar, and the recovery rate of the ultrafiltration system is adjusted to 95%. 1.2mg / L, total iron content less than 0.04mg / L, SiO 2 The content is 3...

Embodiment 3

[0048] High temperature wastewater treatment process such as figure 1 As shown, the 80 ° C MTO process stripper purified water A is discharged into the precipitation separation system 1, wherein the water quality of the stripper tower is as described in Example 1, and the same pretreatment process in Example 1 is adopted. After pretreatment The process water quality is as described in Example 1.

[0049] The pretreated wastewater is sent to the ultrafiltration system 3 through the centrifugal pump 2. The pore size of the ultrafiltration membrane is 0.02 μm and the 19-channel tubular ceramic ultrafiltration membrane is selected, and the effective membrane area is 1m 2 , the membrane filtration flux is 100L / m 2 h, the water supply pressure of the ultrafiltration membrane system is 0.15MPa, the recovery rate of the ultrafiltration system is 90%, the ultrafiltration concentrated water is circulated to the sedimentation tank 1, and the ultrafiltration water quality is pH 8.63, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com