Plant soft capsule material and preparation method thereof

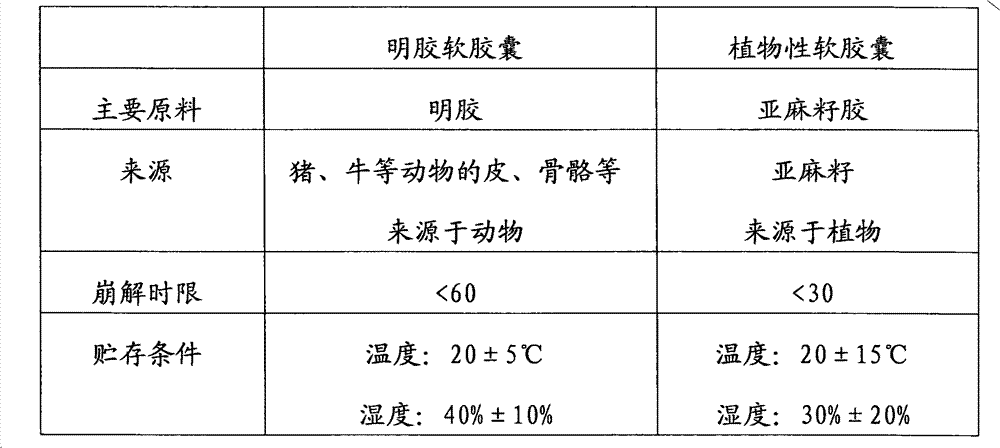

A soft capsule, plant-based technology, applied in the field of plant-based soft capsule material and its preparation, can solve the problems of lack, prolonged dissolution time, changes in effective drug components, etc., to ensure stability, avoid insufficient toughness, and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First, add 9988g of water into the container, weigh 1g of linseed gum, add it into the water, and stir for 10-20 minutes until the linseed gum and water are completely dissolved. Then, add thickener pullulan 2g, film-forming agent carboxymethylcellulose sodium 2g and binder maltose 2g respectively, stir constantly, wait for linseed gum and pullulan, carboxymethylcellulose sodium, Stir the maltose evenly and let it stand for 1 hour to defoam. Next, 5 g of plasticizer glycerin was added, heated to 40° C., and stirred. After stirring evenly, the temperature was kept, and after defoaming at rest for 5 hours, a glue solution was obtained. Finally, the solution was pressed into a film with a thickness of 3 mm, and placed in an environment of 30° C. for 10 hours to dry to obtain the soft capsule material.

Embodiment 2

[0038] First, add 40g of water to the container, weigh 20g of linseed gum, add it to the water, wait until the linseed gum and water are completely dissolved, and let stand for 2 hours to defoam. Then, 10 g of thickener guar gum and 10 g of film-forming agent gum arabic were added respectively, and stirred continuously. After the linseed gum, guar gum, and gum arabic were completely stirred evenly, they were allowed to stand for 1 hour for defoaming. Next, 10 g of plasticizer glycerin and 10 g of polyethylene glycol were added and stirred. After stirring evenly, the mixture was heated to 100° C., kept at the temperature, and left to stand for 5 hours to defoam to obtain a glue solution. Finally, the solution was pressed into a film with a thickness of 3 mm, and dried at 40° C. for 10 hours to obtain the soft capsule material.

Embodiment 3

[0040] First, add 4900g of water to the container, weigh 5g of linseed gum, add it to the water, wait until the linseed gum and water are completely dissolved, and let stand for 2 hours to defoam. Then, add 10g of thickener guar gum, 10g of film-forming agent gum arabic, and 25g of binder starch respectively, and keep stirring until the linseed gum, guar gum, gum arabic, and starch are completely stirred evenly and then stand for 1h Perform defoaming. Next, add 30 g of plasticizer glycerin and 20 g of polyethylene glycol, stir, and after stirring evenly, heat to 100° C., keep the temperature, and stand for 5 hours to defoam to obtain a glue solution. Finally, the solution was pressed into a film with a thickness of 3 mm, and dried at 40° C. for 10 hours to obtain the soft capsule material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com