Method of manufacturing oxygen-nitrogen-oxygen laminated structure and gate

A technology of a laminated structure and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, semiconductor devices, etc., to achieve the effects of increasing the equivalent oxide thickness, increasing the threshold voltage, and reducing charge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

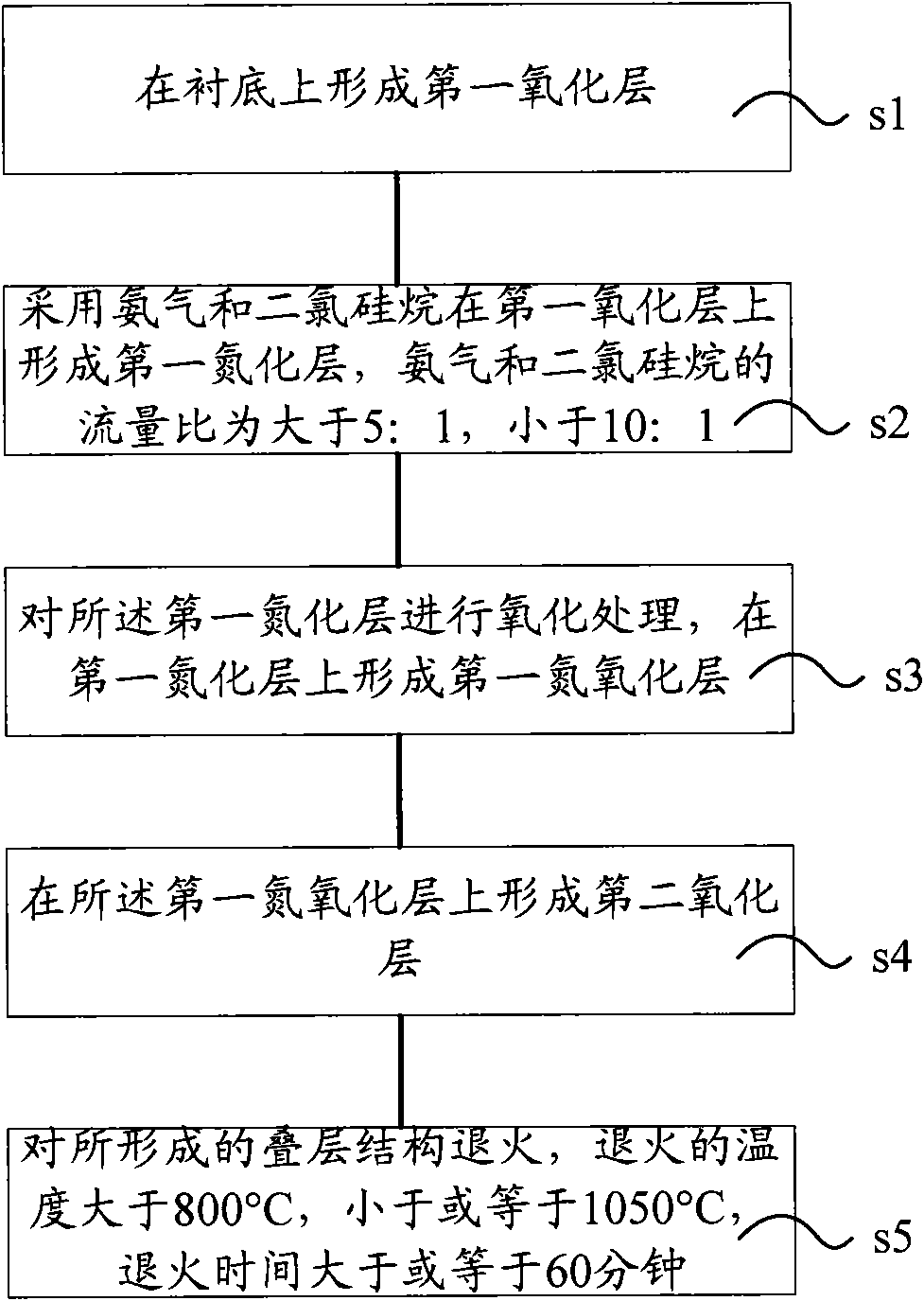

[0029] refer to figure 2 As shown, according to an embodiment of the method for manufacturing the oxygen-nitrogen-oxygen stack structure of the present invention, it includes:

[0030] Step s1, forming a first oxide layer on the substrate;

[0031] Step s2, using ammonia gas and dichlorosilane to form a first nitride layer on the first oxide layer, the flow ratio of ammonia gas and dichlorosilane being greater than or equal to 5:1 and less than 10:1;

[0032] Step s3, performing oxidation treatment on the first nitride layer to partially oxidize the first nitride layer to form a first nitride oxide layer;

[0033] Step s4, forming a second oxide layer on the first oxynitride layer;

[0034] Step s5, annealing the formed laminated structure, the annealing temperature is greater than 800° C. and less than or equal to 1050° C., and the annealing time is greater than or equal to 60 minutes.

[0035] In the above embodiment, when forming the first nitrided layer, the flow ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com