Straight-through electric bag composite dust collector

A technology of electric bag compounding and dust collector, which is applied in the direction of combined devices, chemical instruments and methods, separation methods, etc., can solve the problems of not being able to meet the overall discharge, and achieve the goals of improving market competitiveness, stabilizing the flow rate of flue gas, and reducing the amount of charge loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

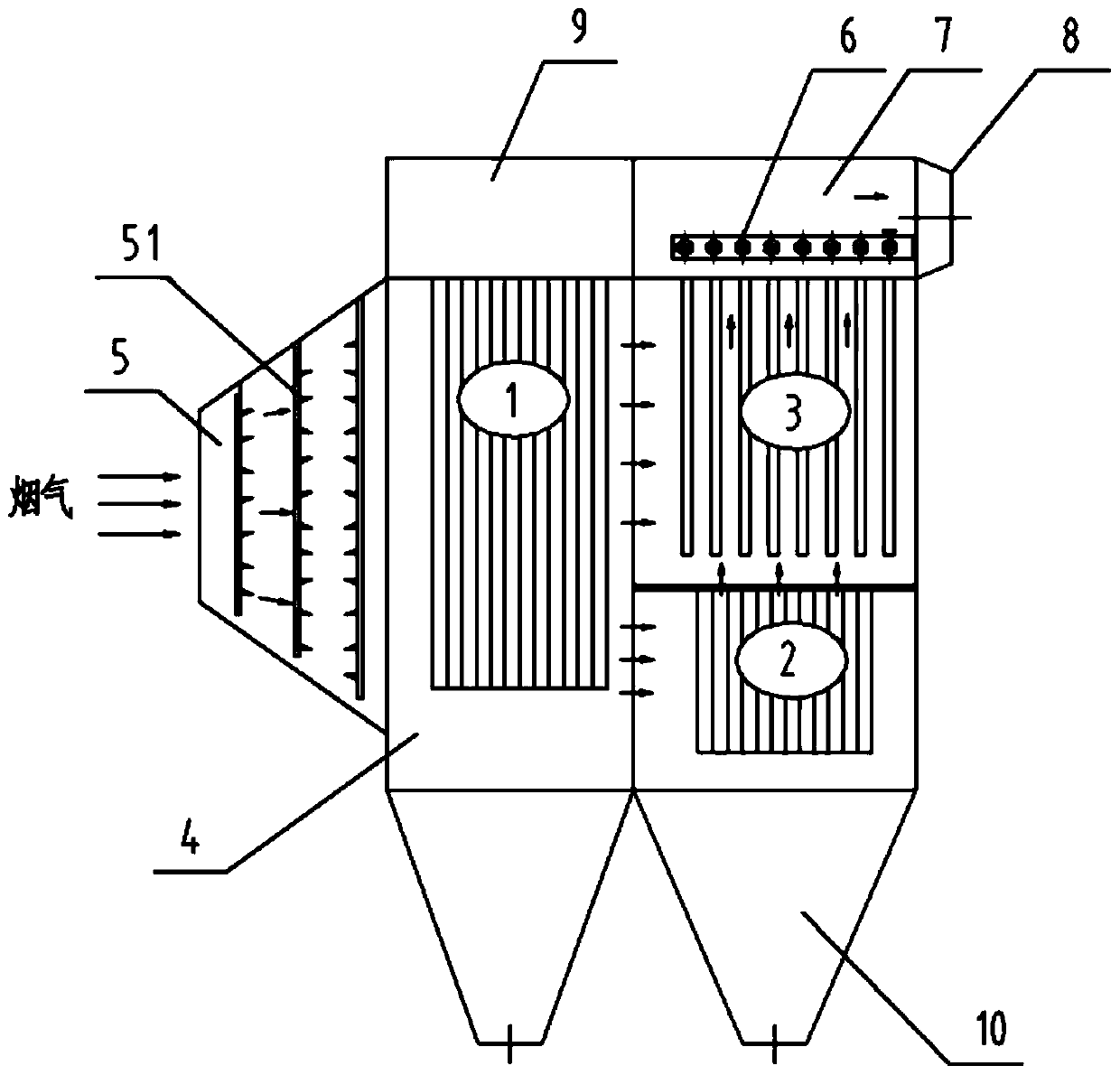

[0037] see figure 1 The embodiment of the present invention is provided with a housing 4, an inlet horn 5, a first-stage electrostatic precipitator 1, a second-stage electrostatic precipitator 2, a filter bag filter device 3, a pulse injection device 6, a clean air chamber 7, and an outlet horn 8. Power supply insulation box 9 and ash hopper 10;

[0038]The inlet horn 5 is arranged at the front end of the housing 4, and the flue gas enters the inlet horn 5 from the inlet of the inlet horn 5, and the inlet horn 5 is provided with an air flow uniform distribution plate 51 with guide vanes, and the outlet of the inlet horn 5 is connected to the housing. The front end of the body 4 is connected, the first-stage electrostatic precipitator 1 is arranged at the front end of the casing 4, the filter bag filter device 3 is arranged at the upper part of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com