Method and device for preparing nano zinc oxide

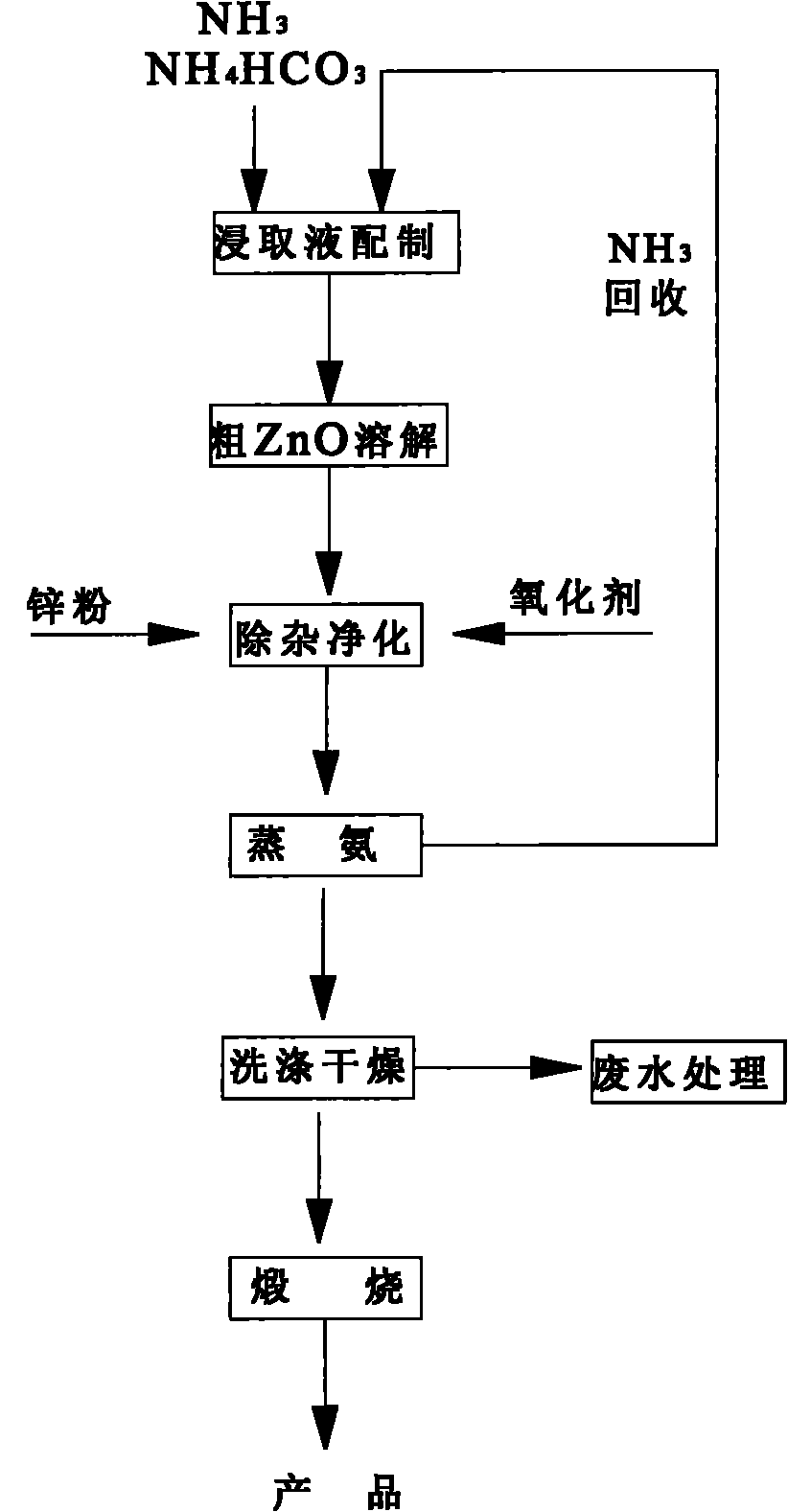

A nano-zinc oxide and zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of non-continuous production, uneven particle size distribution, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

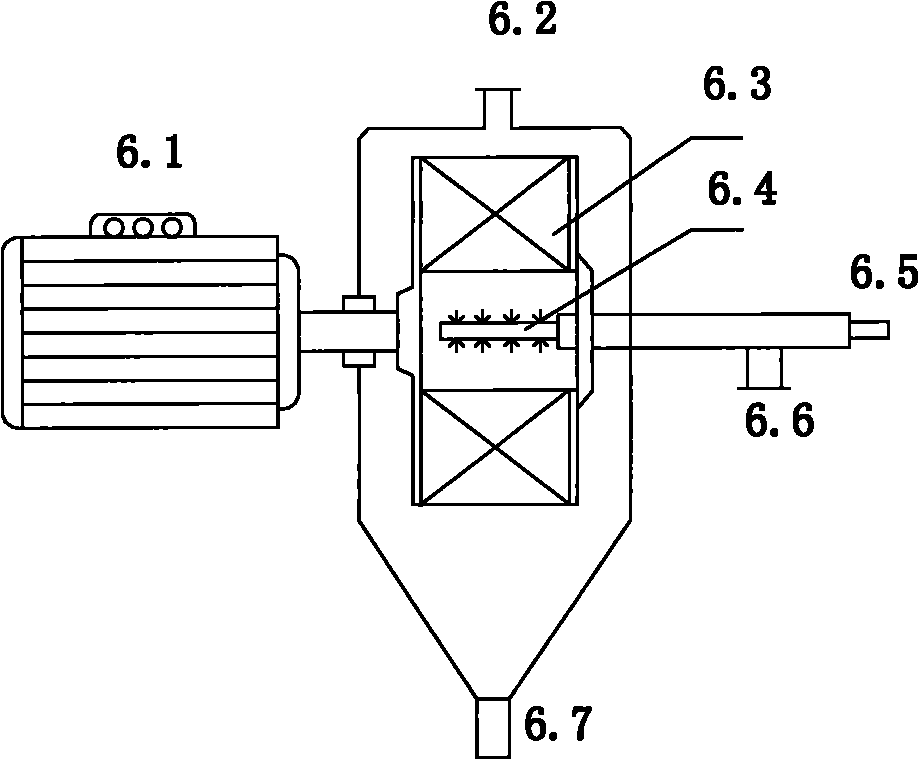

[0026] Put the configured zinc-ammonia complex solution into the storage tank 11, the mass fraction of zinc accounts for 5% of the total mass of the solution, turn on the frequency converter, steam, and circulation pump, and control the speed of the rotating packed bed by adjusting the respective parameters. The steam flow rate is 200r / min, the steam flow rate is 10kg / h, and the liquid flow rate is 400L / h. The packing of the rotating packed bed is stainless steel plate. The temperature of the steam is controlled by adjusting the pressure. The temperature is 120°C. The liquid reacts to generate a basic zinc carbonate mixture with a deamination rate of 95% and a zinc precipitation rate of 98%; then it is roasted in a muffle furnace at a controlled temperature of 350°C for 3 hours, and its average particle size is 80nm.

Embodiment 2

[0028] Put the configured zinc-ammonia complex solution into the storage tank 11, the mass fraction of zinc accounts for 20% of the total mass of the solution, turn on the frequency converter, steam and circulation pump, and control the speed of the rotating packed bed by adjusting the respective parameters The steam flow rate is 800r / min, the steam flow rate is 80kg / h, and the liquid flow rate is 40L / h. The packing of the rotating packed bed is stainless steel plate. The temperature of the steam is controlled by adjusting the pressure. The temperature is 160°C. The liquid reacts to generate a basic zinc carbonate mixture with a deamination rate of 98% and a zinc precipitation rate of 99.9%; then it is roasted in a muffle furnace at a controlled temperature of 450°C for 6 hours, and its average particle size is 21nm.

Embodiment 3

[0030] Put the configured zinc-ammonia complex solution into the storage tank 11, the mass fraction of zinc accounts for 10% of the total mass of the solution, turn on the frequency converter, steam and circulation pump, and control the speed of the rotating packed bed by adjusting the respective parameters The steam flow rate is 2800r / min, the steam flow rate is 50kg / h, and the liquid flow rate is 80L / h. The packing of the rotating packed bed is stainless steel plate. The temperature of the steam is controlled by adjusting the pressure. The temperature is 140°C. The liquid reacts to generate a basic zinc carbonate mixture with a deamination rate of 96% and a zinc precipitation rate of 99.8%; then it is roasted in a muffle furnace at a controlled temperature of 550°C for 4 hours, and its average particle size is 35nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com