Double-wire pulsed welding melten pool bidirectional near-infrared synchronous vision sensing method and device

A visual sensing and two-way synchronization technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of not being able to obtain satisfactory molten pool images, easy to block the molten pool imaging window, etc., and achieve rich image information Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

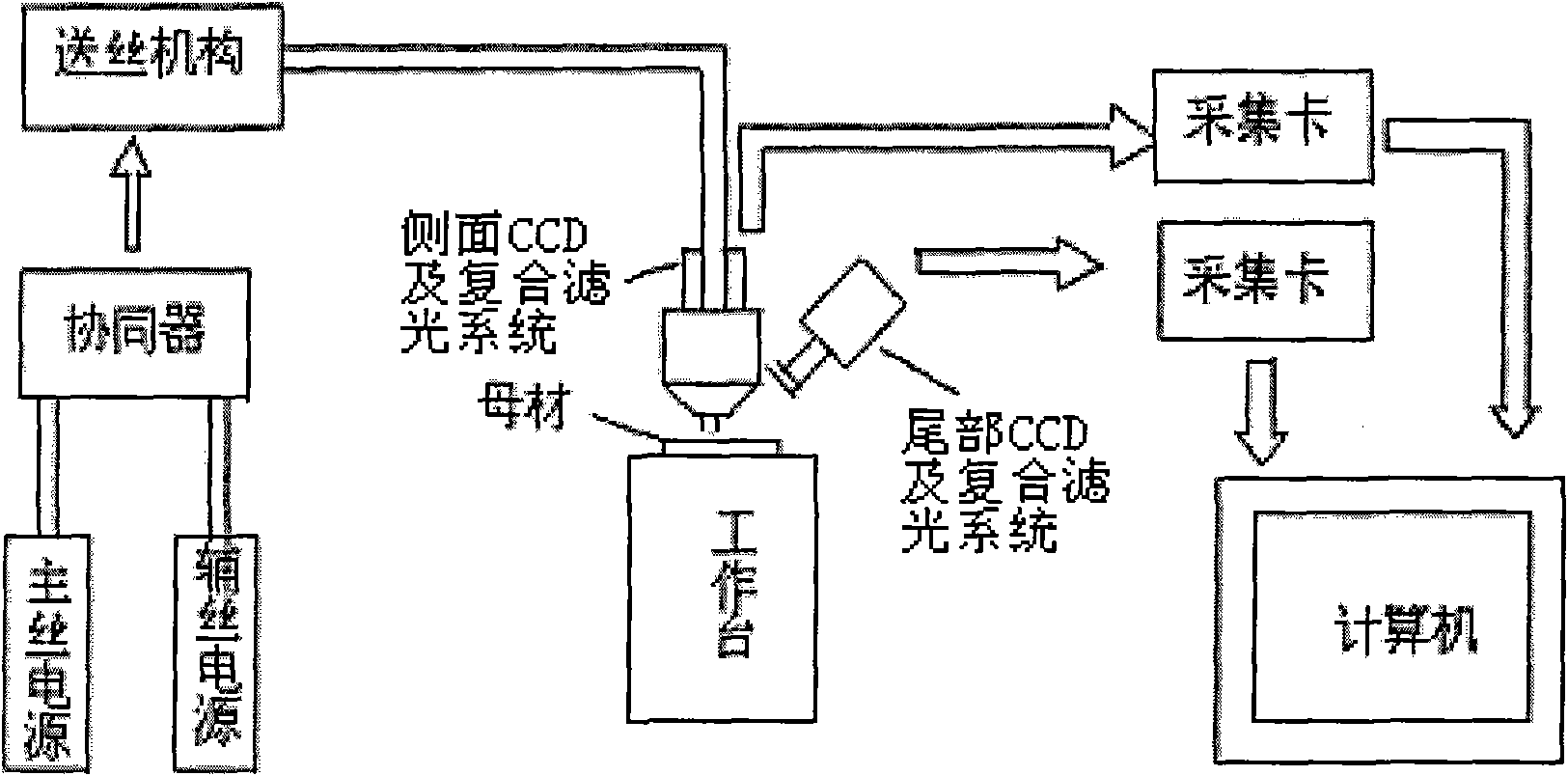

[0012] combine figure 1 , figure 2 , the double-wire pulse welding two-way molten pool near-infrared visual sensing method of the present invention uses the reflected light of the molten pool to the arc and the radiated light of the molten pool itself as light sources during the double-wire pulse welding process, and filters out the double-wire welding process through near-infrared technology The interference of medium and strong arc light on the molten pool is carried out under the condition that the exposure time of the shutter of the CCD visual sensor is less than the pulse change period of the twin wire welding machine. OpenCV's two-way molten pool synchronous acquisition and storage realizes simultaneous visual sensing of the rear and side molten pools of dual-wire pulse welding.

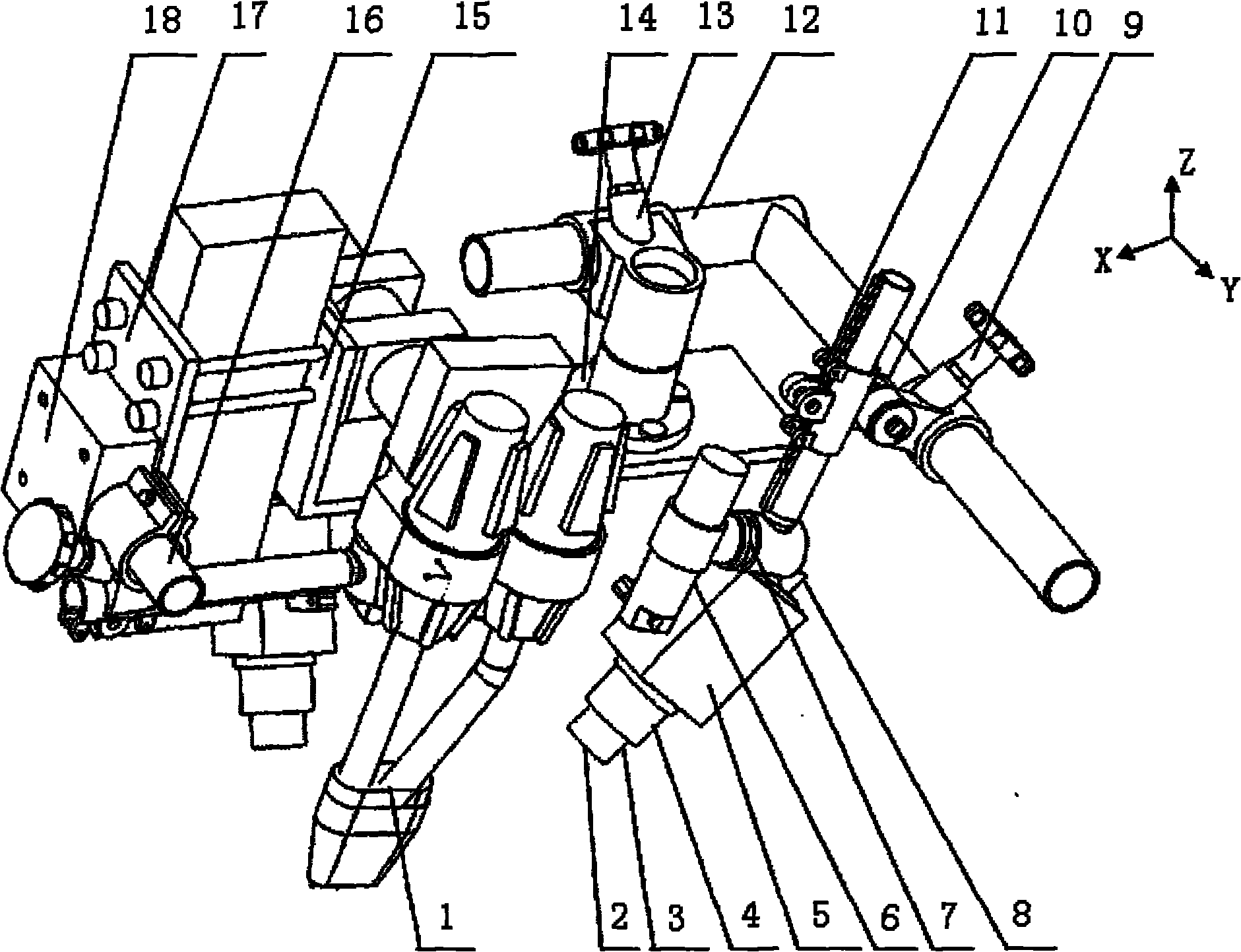

[0013] The double-wire pulse welding two-way molten pool near-infrared synchronous visual sensing device of the present invention includes two near-infrared CCD visual sensors, two sets of ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com