Composition for whitening and removing spots and preparation method thereof

A whitening and freckle-removing composition technology, which is applied in the field of oral whitening and freckle-removing compositions, can solve the problems of low safety, small range of applicable people, and a large number of people, and achieve high safety, wide range of applicable people, and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Preparation of products

[0046] 1. Weigh raw materials:

[0047] Weigh 20g of reduced glutathione, 50g of water-soluble pearl powder, 10g of grape seed extract, 20g of vitamin E, and 5g of vitamin C.

[0048] 2. Preparation steps:

[0049] (1) Put 20g of reduced glutathione, 50g of water-soluble pearl powder, 10g of grape seed extract, 20g of vitamin E and 5g of vitamin C into a mixer and mix for 10 minutes to obtain a semi-finished product.

[0050] (2) Inspection of the semi-finished product: check whether the mixture is evenly mixed according to the prior art, if not, continue to mix and stir in the mixer for 5-10 minutes.

[0051] (3) filling the semi-finished product after passing the inspection in the hard capsule to make a finished capsule, and the content of each finished capsule weighs 0.5g.

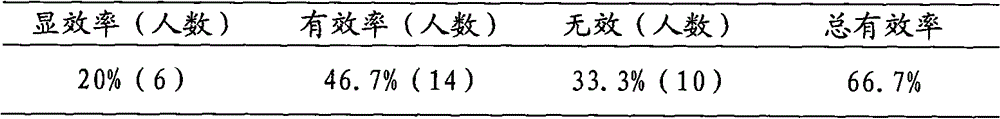

[0052] Two, the freckle-removing effect experiment of embodiment 1 product:

[0053] 1. Experimental conditions:

[0054] ①Eligibility conditions for participant...

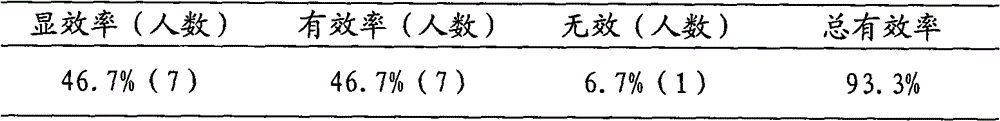

Embodiment 2

[0066] 1. Preparation of products

[0067] 1. Weigh raw materials:

[0068] Weigh 50g of reduced glutathione, 30g of ordinary pearl powder, 30g of grape seed extract, 15g of vitamin E, 15g of vitamin C, and 1.5g of hypromellose.

[0069] 2. Preparation steps

[0070] (1) 1.5 g of the weighed hypromellose binder was prepared into a 5% hypromellose aqueous solution.

[0071] (2) Place 50 g of reduced glutathione, 30 g of ordinary pearl powder, 30 g of grape seed extract, 15 g of vitamin E and 15 g of vitamin C into a mixer, and mix for 20 minutes to obtain a mixed powder.

[0072] (3) Add 5% hypromellose aqueous solution into the mixed powder, stir the mixed powder and 5% hypromellose aqueous solution evenly, make granules, and dry at 55° C. for 4 hours to obtain a semi-finished product.

[0073] (4) Inspection of semi-finished products.

[0074] (5) Press the qualified semi-finished product into tablets with a tablet press to make finished tablets with a weight of 0.5 g eac...

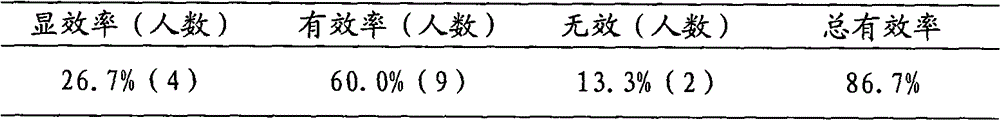

Embodiment 3

[0090] 1. Preparation of products

[0091] 1. Weigh raw materials:

[0092] Weigh 70g of oxidized glutathione, 10g of ordinary pearl powder, 50g of grape seed extract, 5g of vitamin E, 20g of vitamin C, 14g of maltitol, and 1.5g of hypromellose.

[0093] 2. Preparation steps:

[0094] (1) 1.5 g of the weighed binder hypromellose was formulated into a 5% hypromellose aqueous solution.

[0095] (2) Place 70 g of oxidized glutathione, 10 g of common pearl powder, 50 g of grape seed extract, 5 g of vitamin E, 20 g of vitamin C and 14 g of maltitol that have been weighed into a mixer, and mix for 30 minutes to obtain a mixed powder. Here maltitol is used to adjust the mouthfeel of the product.

[0096] (3) Add 5% hypromellose solution into the mixed powder, stir the mixed powder and 5% hypromellose aqueous solution evenly to make granules, and dry the granules to make semi-finished products.

[0097] (4) Inspection of semi-finished products.

[0098] (5) Pack the qualified sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com