Comprehensive impurity eliminating and screening equipment for tobacco stems

A screening equipment and tobacco stem technology, applied in the field of multi-functional tobacco stem screening equipment, can solve the problems of adverse product quality, single function, product quality impact, etc., achieving strong comprehensive rejection ability, simple equipment structure, shortening production The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

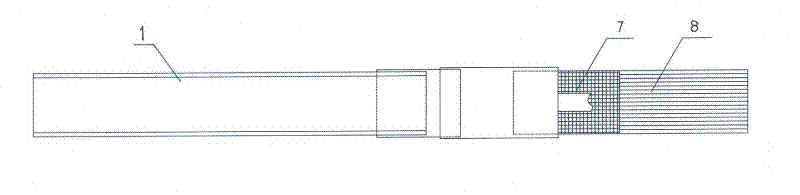

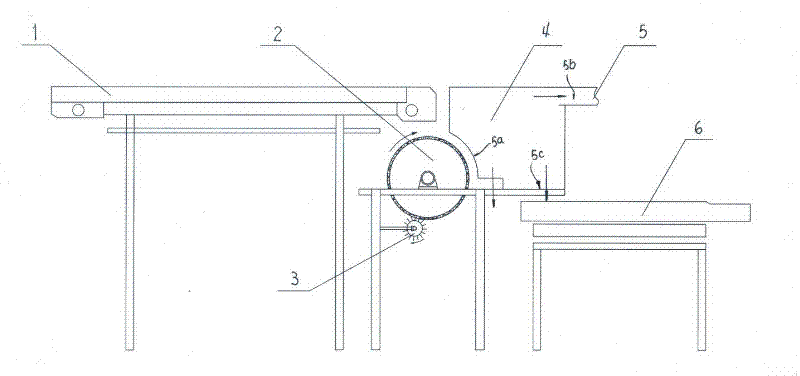

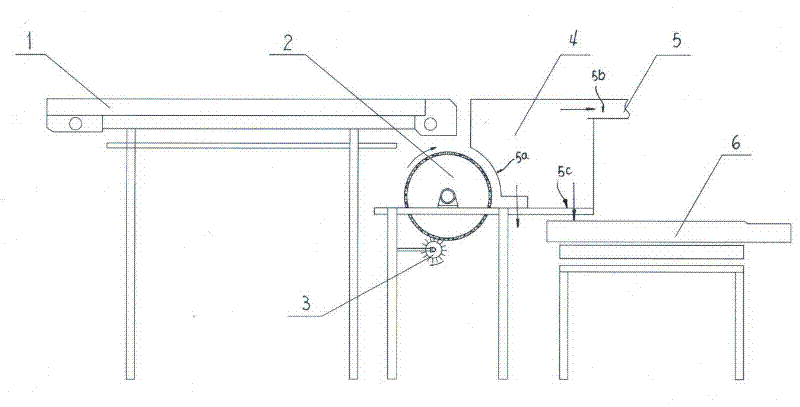

[0011] figure 1 Shown is a tobacco stem comprehensive removal and screening equipment, including a belt conveyor 1, a screening machine 6, an electromagnetic roller type rejector 2 is arranged below the discharge end of the belt conveyor 1, and it is installed by an electromagnetic roller wrapped with felt. It is formed on an adjustable-speed drive motor; the cleaning brush 3 is arranged on the lower part of the electromagnetic roller wrapped with felt and contacts it, the air suction port 5a of the dust removal device 4 is arc-shaped similar to the electromagnetic roller, and the air suction port is arranged on the felt-wrapped Above the side of the electromagnetic roller, the air outlet 5b of the dust removal device is connected with the dust removal suction duct 5, and a storage box for collecting sundries with a specific gravity greater than tobacco stems is provided below the inner side of the discharge port of the dust removal device. The screening machine 6 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com