Weighing module

A weighing module and weighing sensor technology, applied in the direction of weighing, detailed information of weighing equipment, instruments, etc., can solve problems such as complex structure, material tank overturning, material tank falling, etc., to achieve safety and convenient adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

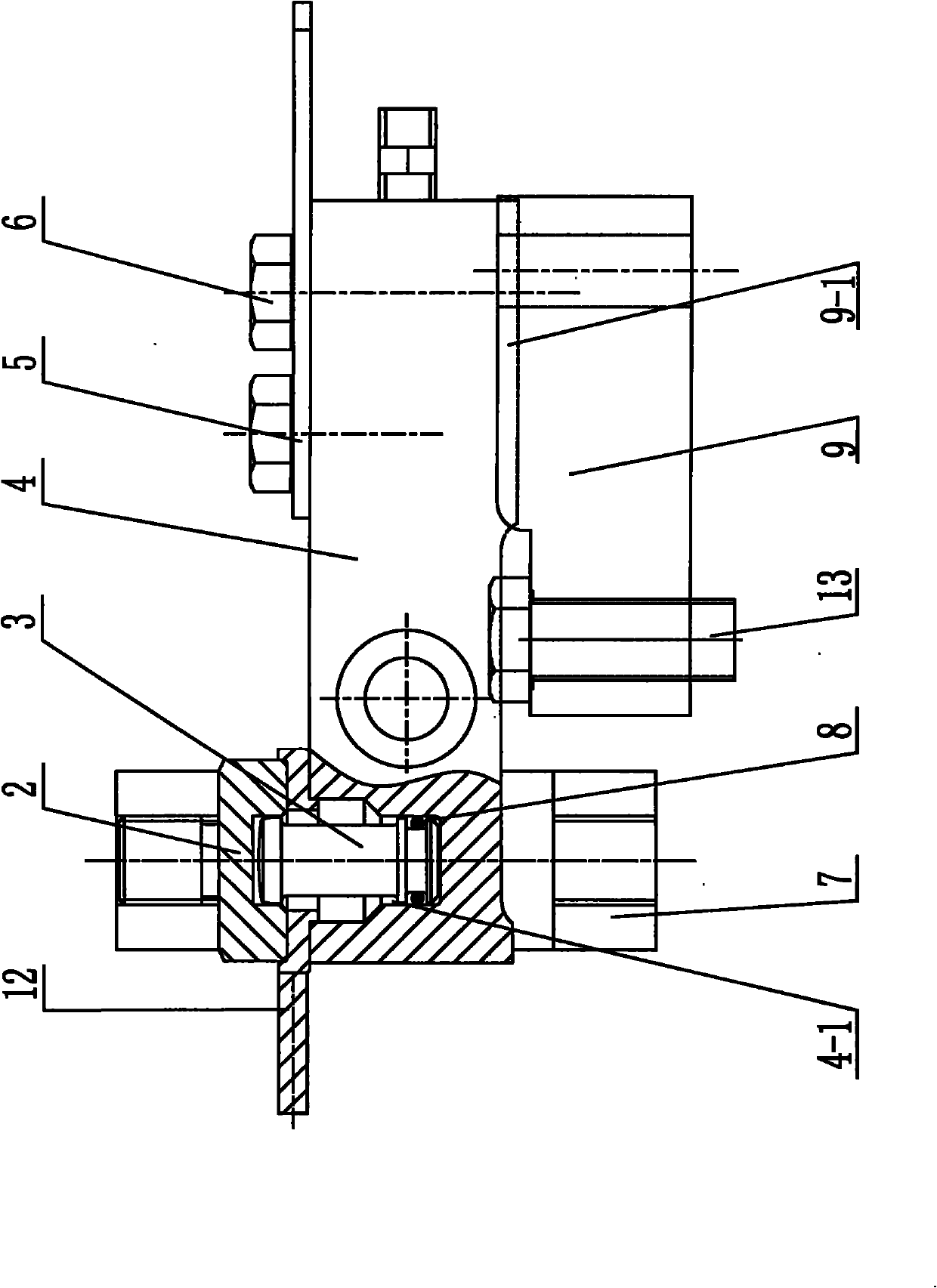

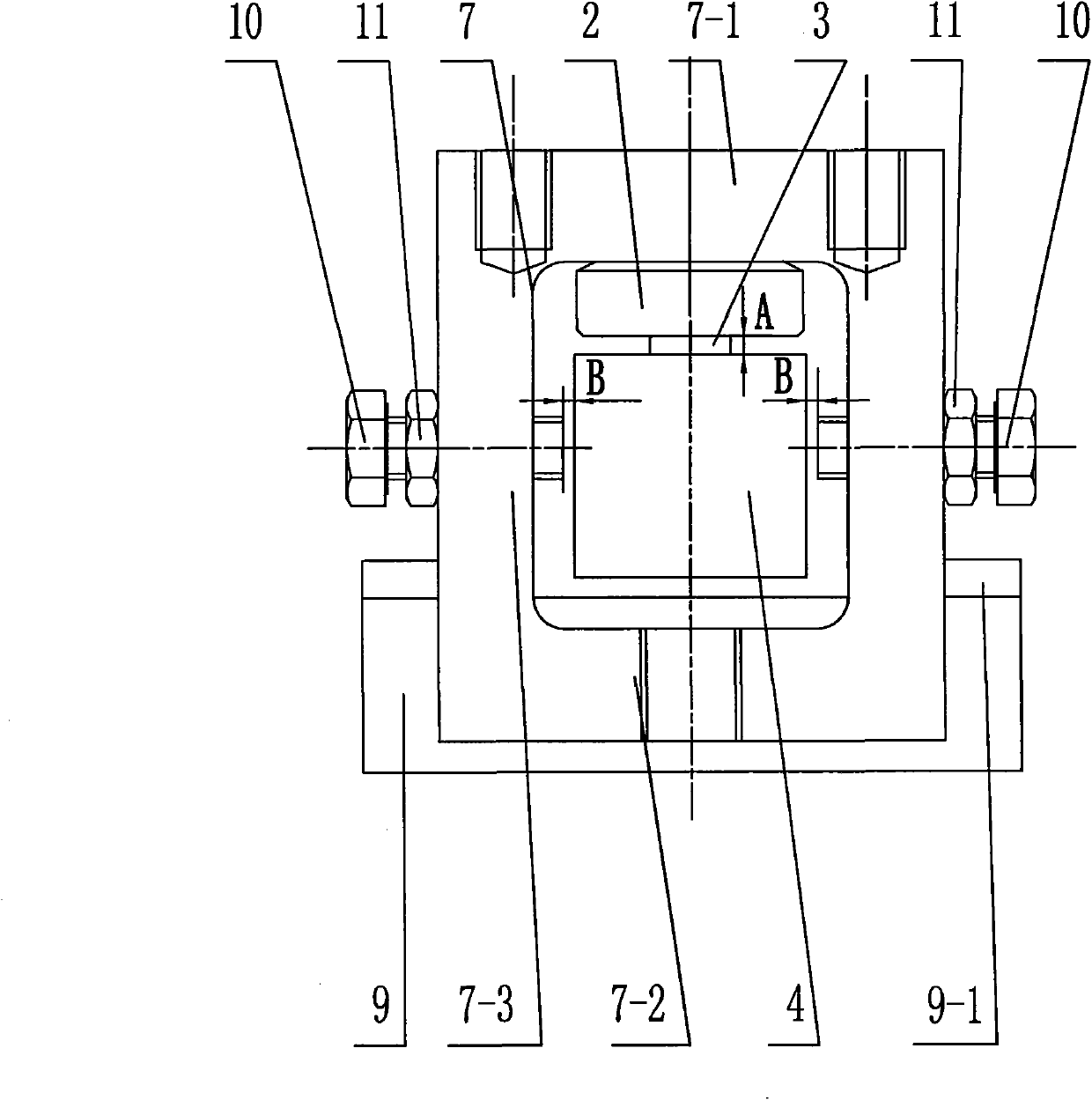

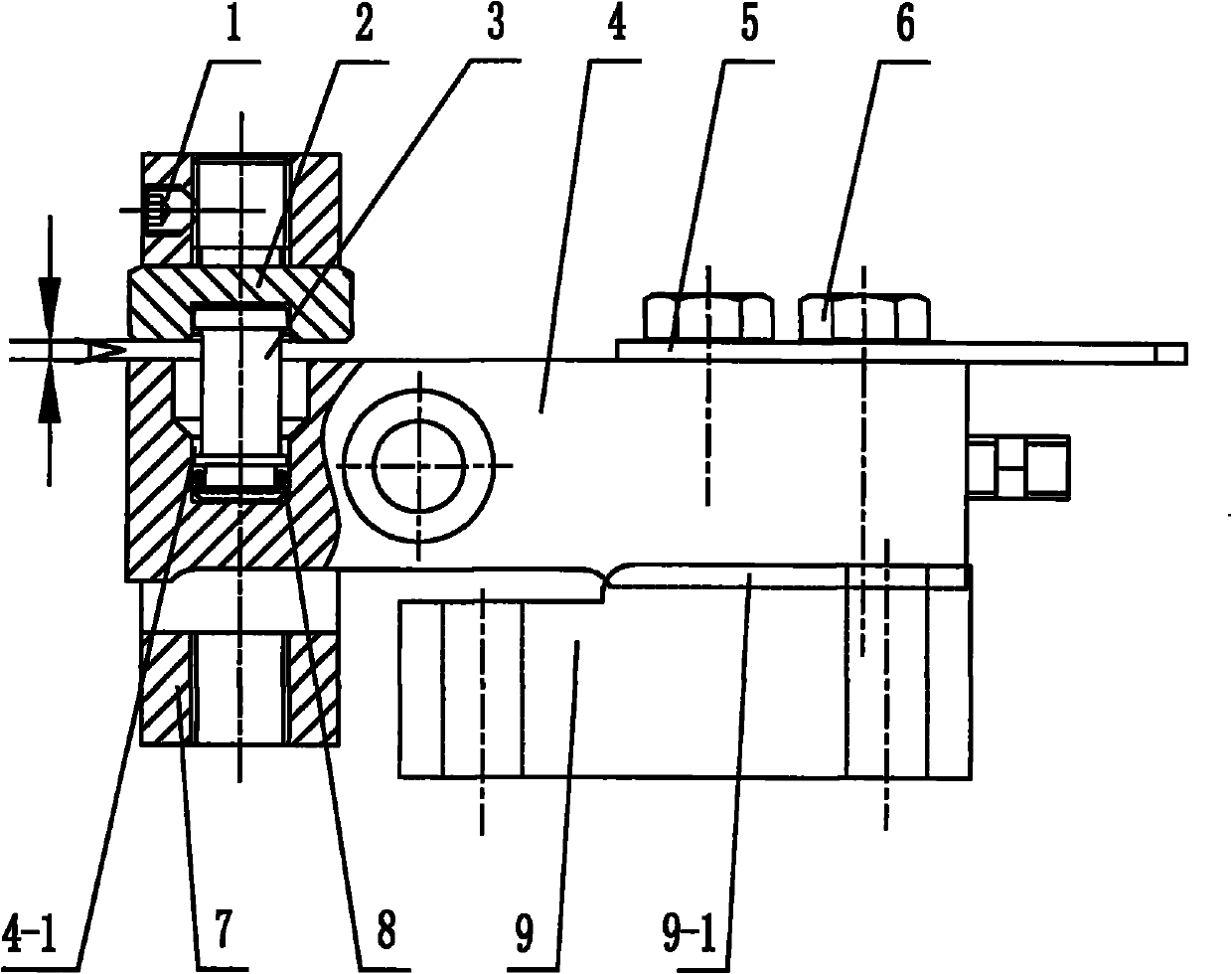

[0019] See Figure 1~4 As shown, the weighing module of the present invention includes a base 9 and a load cell 4, the load cell 4 adopts a conventional shear cantilever beam sensor, and the load cell 4 connection side is installed on the base 9 by a fastener, the load cell 4 of the present invention The base 9 is provided with a limit groove 9-1, and the two sides of the load cell 4 are in contact with the wall of the limit groove 9-1, and the base 9 is used to withstand the external force in the horizontal direction of the module, and the load cell 4 Playing a protective role, the base 9 is provided with more than two mounting holes, through which the connecting bolts 13 are connected with the machine base to achieve the effect of preventing overturning. See Figure 1~3 As shown, the bearing side of the load cell 4 of the present invention is provided with a blind hole 4-1 along the vertical direction, and the blind hole 4-1 is a step-shaped blind hole. threaded column, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com