Double-bow cut-off device for detecting pantograph pressure of engine

A pantograph and pressure technology is applied in the field of double-bow cut-off devices for locomotive pantograph pressure detection. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

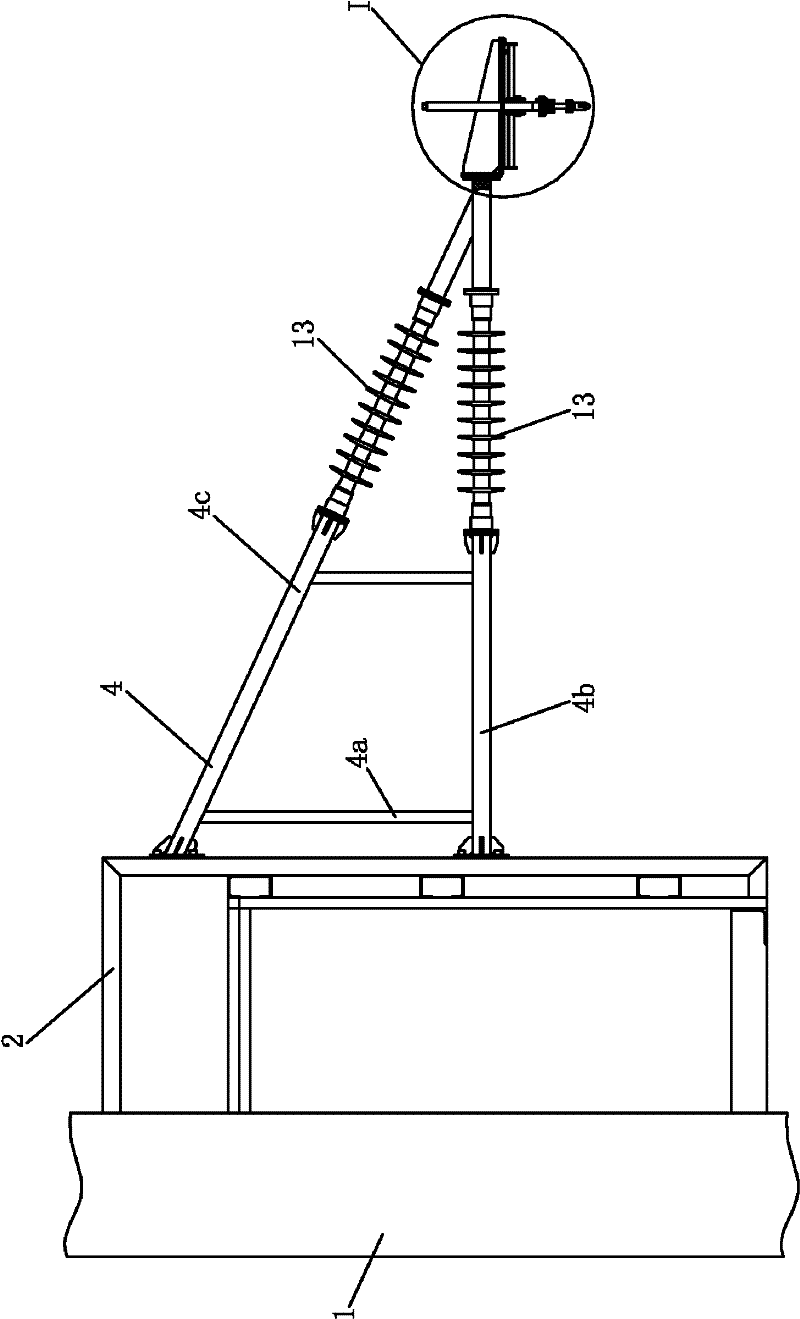

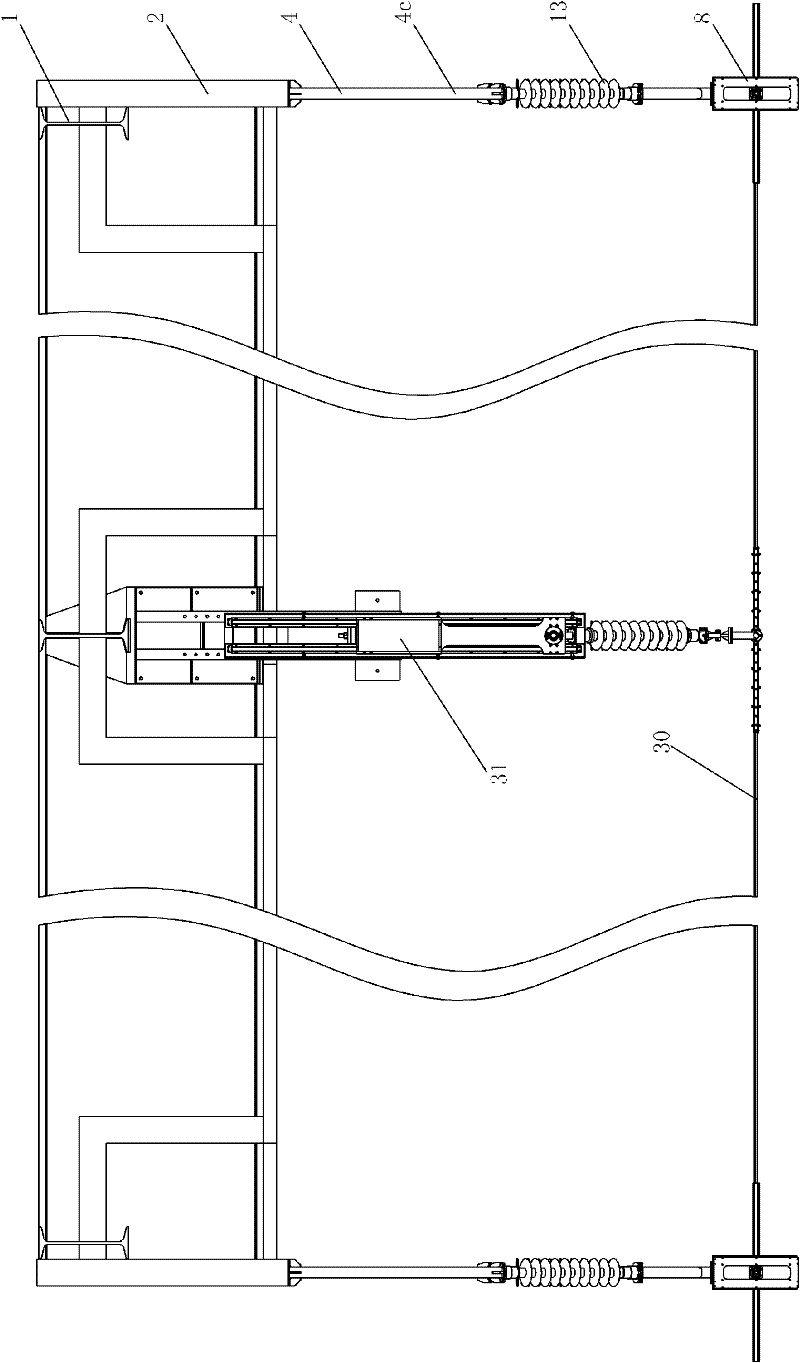

[0022] figure 1 , 2 It is shown that a specific embodiment of the present invention is: a double-bow partition device for locomotive pantograph pressure detection, a mounting frame 2 is fixed on the inside of the column 1 on the outside of the track, and the mounting frame 2 is connected with the insulating connecting frame 4 and The disconnectors are fixedly connected.

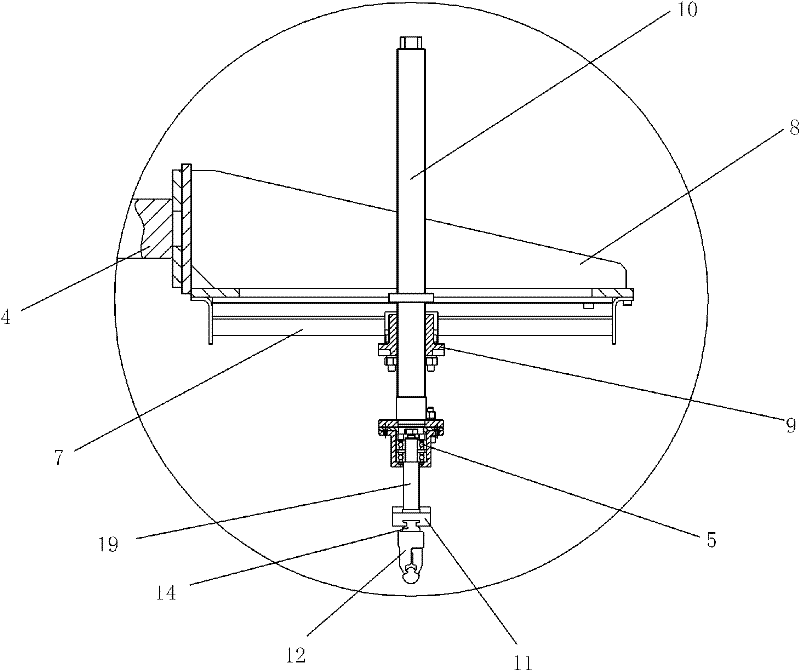

[0023] The specific structure of the partition is: the working platform 8 is fixedly connected with the connecting frame 4, the bottom of the working platform 8 is fixed with a horizontal slide rail 7, the horizontal slide seat 9 is fitted on the horizontal slide rail 7, and the center of the vertical lifting rod 10 The lower screw rod is connected in the nut of the transverse sliding seat 9, the lower end of the lifting rod 10 is connected to the outer ring flange of a bearing 5, the inner ring of the bearing 5 is fixedly connected to the upper end of the connecting rod 19, and the lower end of the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com