Mixed refrigerant and nitrogen expansion combinational refrigeration type natural gas liquefying method

A technology of mixing refrigerant and natural gas, applied in refrigeration and liquefaction, liquefaction, recovery of liquid hydrocarbon mixture, etc., can solve the problem of high purity requirements of pure refrigerant components, difficult configuration of refrigerant component proportions, and large volume flow of gaseous refrigerants and other problems, to achieve the effect of low refrigerant composition requirements, reduction of operation labor intensity, and reduction of equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

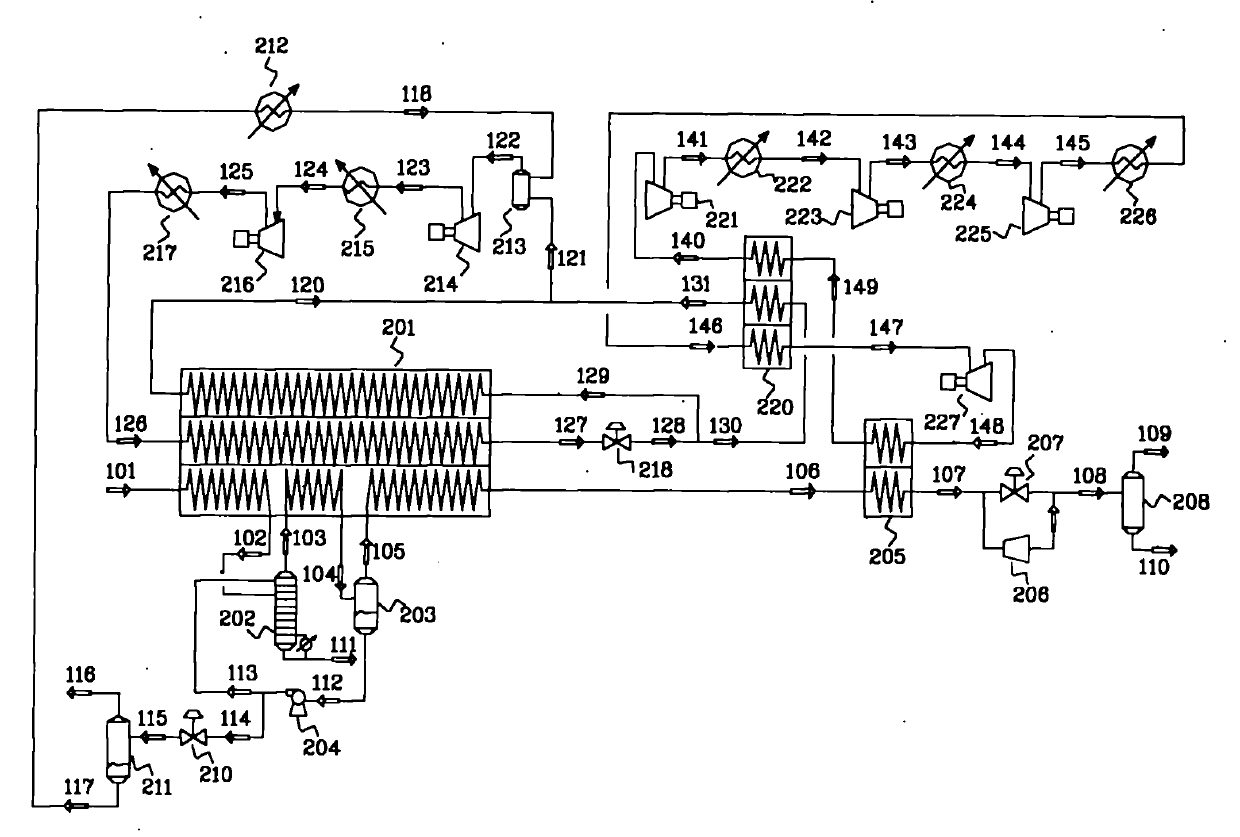

[0010]The process and device system involved in this embodiment includes a mixed refrigerant refrigeration unit, a mixed refrigerant compression unit, a nitrogen expansion refrigeration unit, a nitrogen compression unit, a heavy hydrocarbon removal unit, and a mixed refrigerant preparation supplementary unit; the main body of the device used includes Liquefaction section cold box 201, subcooling section cold box 205, nitrogen heat exchanger 220, LNG J-T valve 207, liquid expander 206, LNG storage tank 208, mixed refrigerant J-T valve 218, mixed refrigerant buffer tank 213, mixing Refrigerant primary compressor 214, mixed refrigerant primary cooler 215, mixed refrigerant secondary compressor 216, mixed refrigerant secondary cooler 217, nitrogen primary compressor 221, nitrogen primary cooler 222, nitrogen Secondary compressor 223, nitrogen secondary cooler 224, nitrogen tertiary compressor 225, nitrogen tertiary cooler 226, nitrogen expander 227, heavy hydrocarbon removal tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com