Method for preparing nanometer ATO dispersing slurry fast, efficiently and cheaply

A nano-dispersion, ATO technology, used in polyurea/polyurethane coatings, dyeing physical treatment, fibrous fillers, etc., can solve the problems of low efficiency, power consumption, poor slurry dispersion effect, etc., to achieve low cost, improve efficiency, The effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

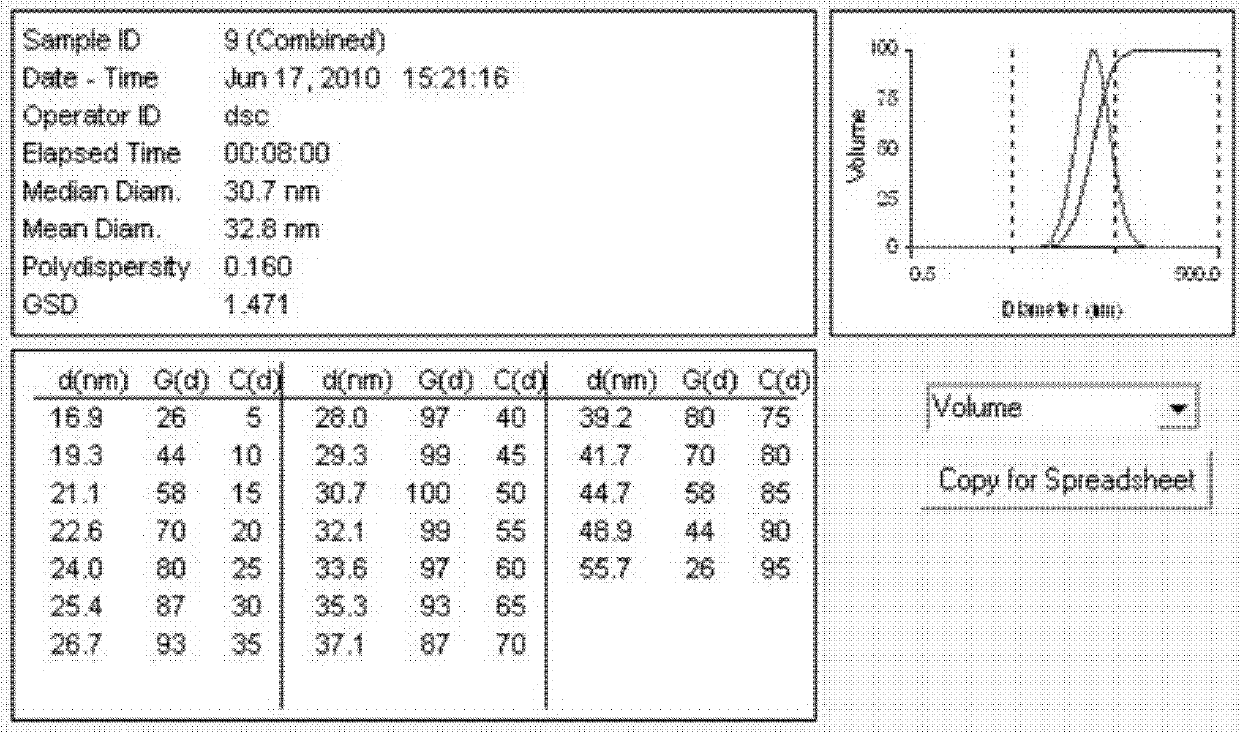

[0040] Measure 490 mL of distilled water, add 2.1 mL of KH570 while stirring, then add 210 g of ATO powder (produced by Shanghai Huzheng Nano Co., Ltd.), and adjust the pH value of the slurry to 10 with NaOH solution (1.0 mol / L). After fully stirring, add it into a stainless steel ball mill tank with a volume of 3L (select 2100g of zirconium beads with a diameter of 1.0mm, and its volume is about twice the volume of the ATO powder), and adjust the total mass of the corresponding two tanks to be equal. Ball mill on a domestic planetary ball mill (QM-2SP12) with a rotation rate of 380rpm. After 7.5 hours, the slurry was taken out to adjust the pH value to 8.0, and then centrifuged at 4000r / min for 40 minutes, the solid content still reached more than 27%, and it was placed stably for half a year without obvious settlement. Particle size and distribution see figure 1 , confirmed to have reached the nanoscale dispersion.

Embodiment 2

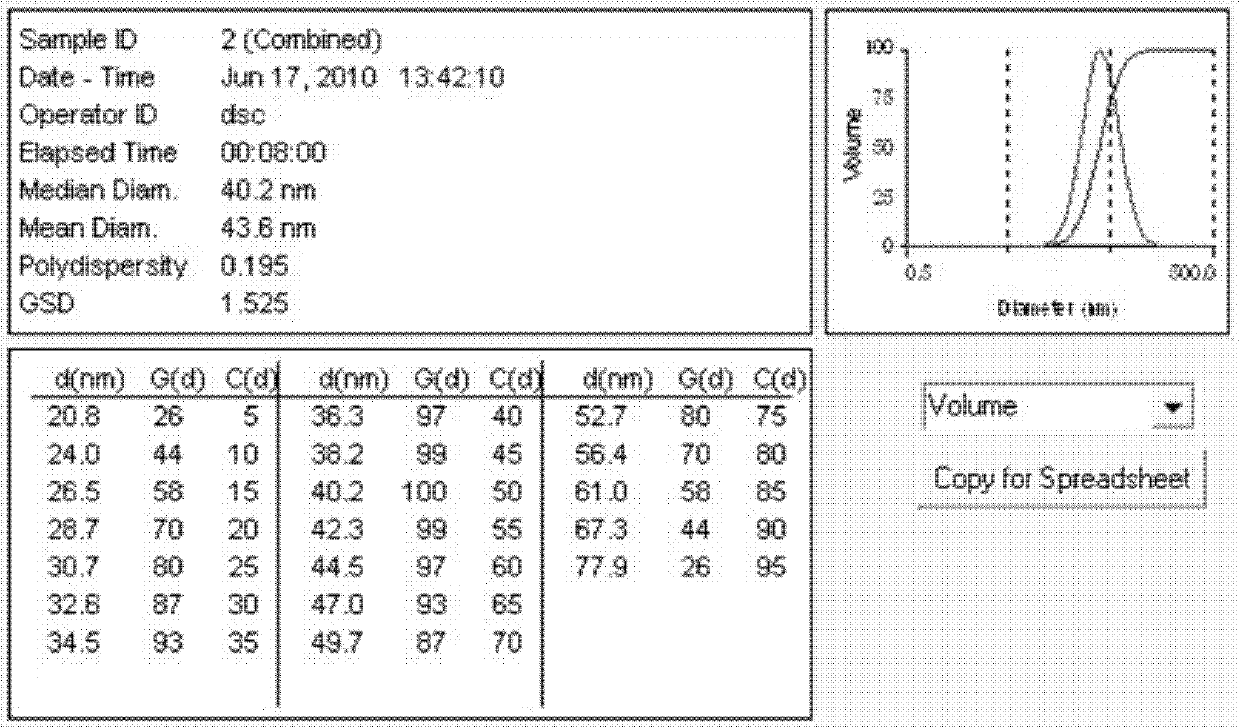

[0042] The formula and other processes of ball milling are the same as in Example 1, but the zirconium beads are replaced with those with a diameter of 0.2 mm, and the time is shortened to 5 hours. The obtained slurry has a solid content of more than 27%, and can be placed stably for half a year without obvious settlement. Its particle size and distribution are shown in figure 2 , confirmed to have reached the nanoscale dispersion.

Embodiment 3

[0044] Other formulations and ball milling process are the same as in Example 1, but the dispersant KH570 is replaced by KH560, the dosage is equivalent to 1.8% of ATO mass, and the time is shortened to 6h. The obtained slurry has a solid content of more than 27%, and can be placed stably for half a year without obvious settlement. Its particle size and distribution are shown in image 3 , confirmed to have reached the nanoscale dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com