Patternable environmental catalysis materials and size preparation method thereof

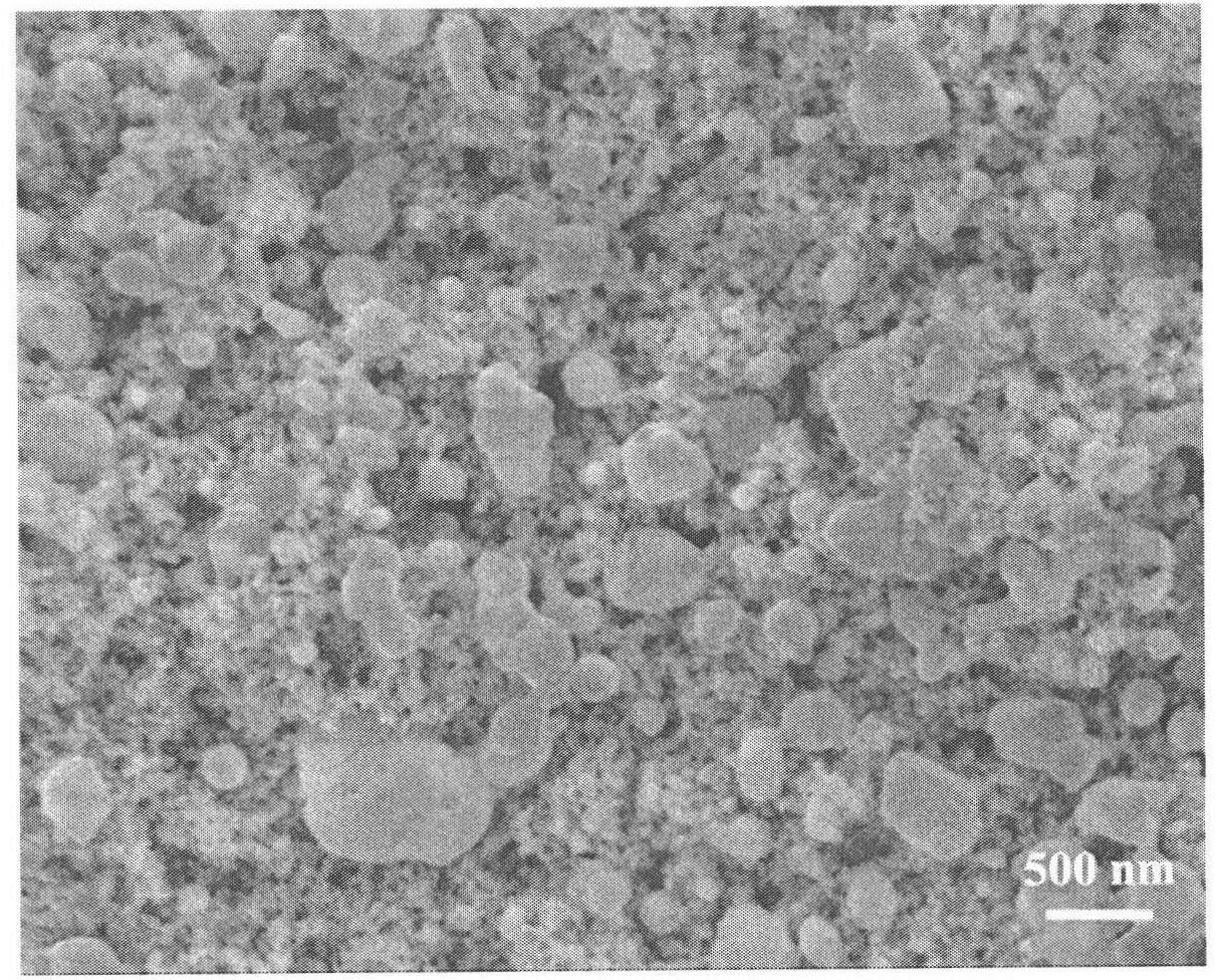

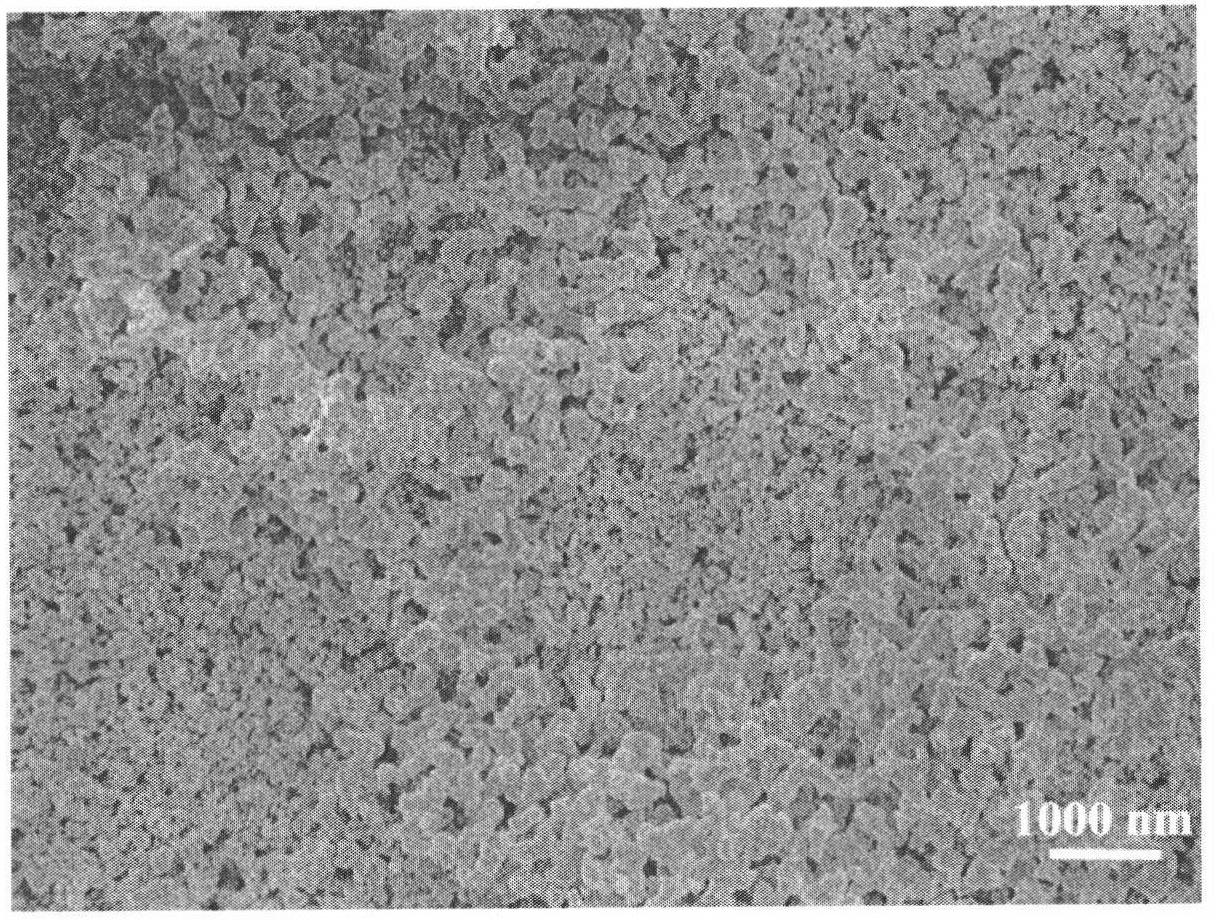

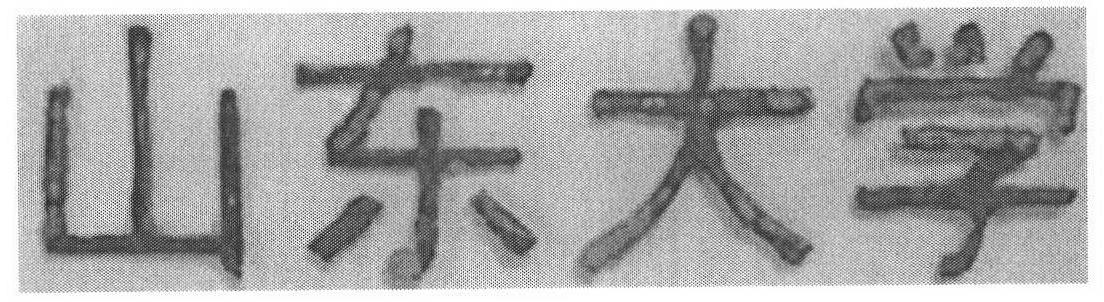

A catalytic material and patterning technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems affecting physical and mental health, work and study, incomplete degradation, Long degradation time and other problems, to achieve the effect of good visual effect, exquisite pattern and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A slurry of a patternable environmental catalytic material, the preparation method of which is as follows:

[0051] (a) Preparation of titanium dioxide (TiO 2 ) slurry (grinding method): Measure 5mL small molecule organic acid-formic acid and 20mL 0.01-0.5M silver nitrate solution to mix, add 1-10 drops of surfactant polyethylene glycol octylphenyl ether (Triton X -100), stirred at room temperature for 10-15 minutes to obtain a titanium dioxide slurry; weigh 1-3g of commercially available TiO 2 Powder-Degussa nano-titanium oxide (DegussaP25), while grinding, drop 5mL of the titanium dioxide slurry grinding solution prepared above, and the grinding time is 30 minutes, until a uniformly mixed white slurry is formed to obtain TiO 2 slurry;

[0052] (b) Preparation of alumina (Al 2 o 3 ) slurry (sol-gel method): Weigh 6.72g aluminum nitrate or its crystalline hydrate and dissolve it in 50-100mL water, add 0.48 aluminum foil, and reflux in the reflux device for 100 minut...

Embodiment 2

[0068] Preparation steps are the same as example 1, the difference is: prepare TiO 2 In the process of slurry, measure 8mL of small molecular organic acid-formic acid and mix it with 25mL of water.

Embodiment 3

[0070] Preparation steps are the same as example 1, the difference is: prepare TiO 2 During the slurry process, add 1-10 drops of surfactant as alkylphenol polyoxyethylene ether (OP-10).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com