PCB and PIN crimping device and use method thereof

A technology of PCB board and needle pressing, applied in the structural connection of printed circuits, multi-layer circuit manufacturing, printed circuit components, etc., can solve the problems of increased manufacturing costs, component damage, low transmission speed, etc., and achieve the reduction of complex requirements , Improve production efficiency and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

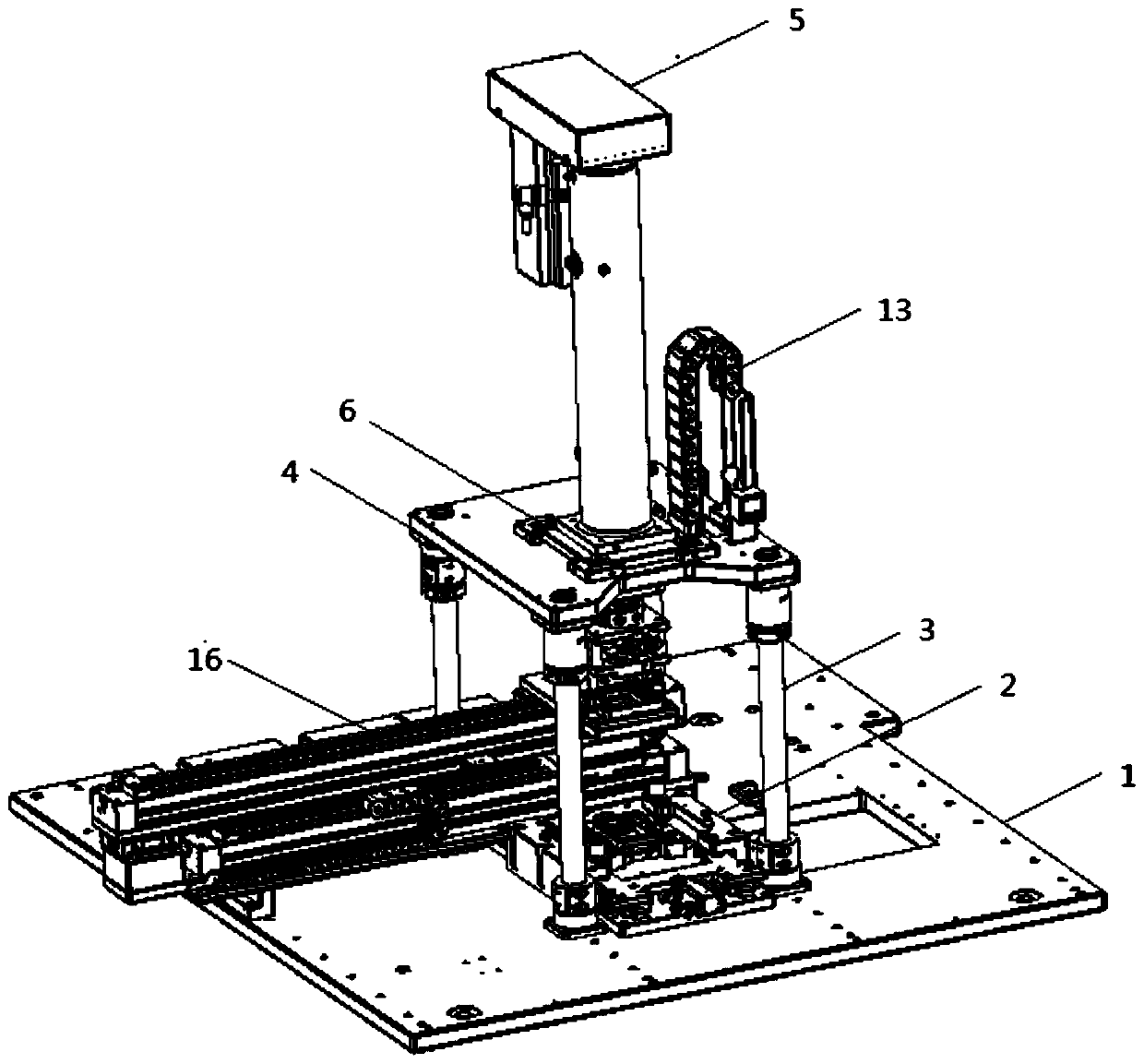

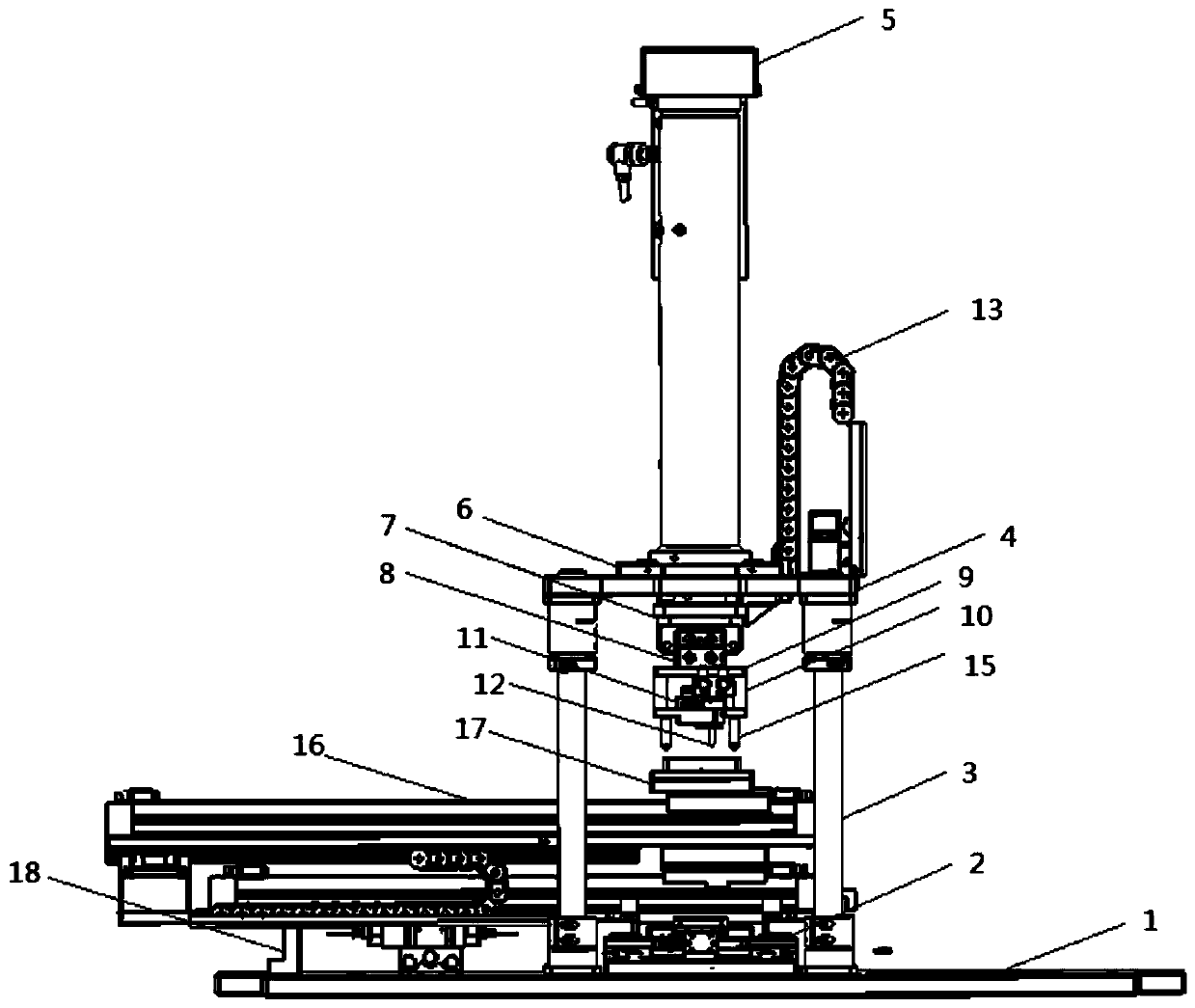

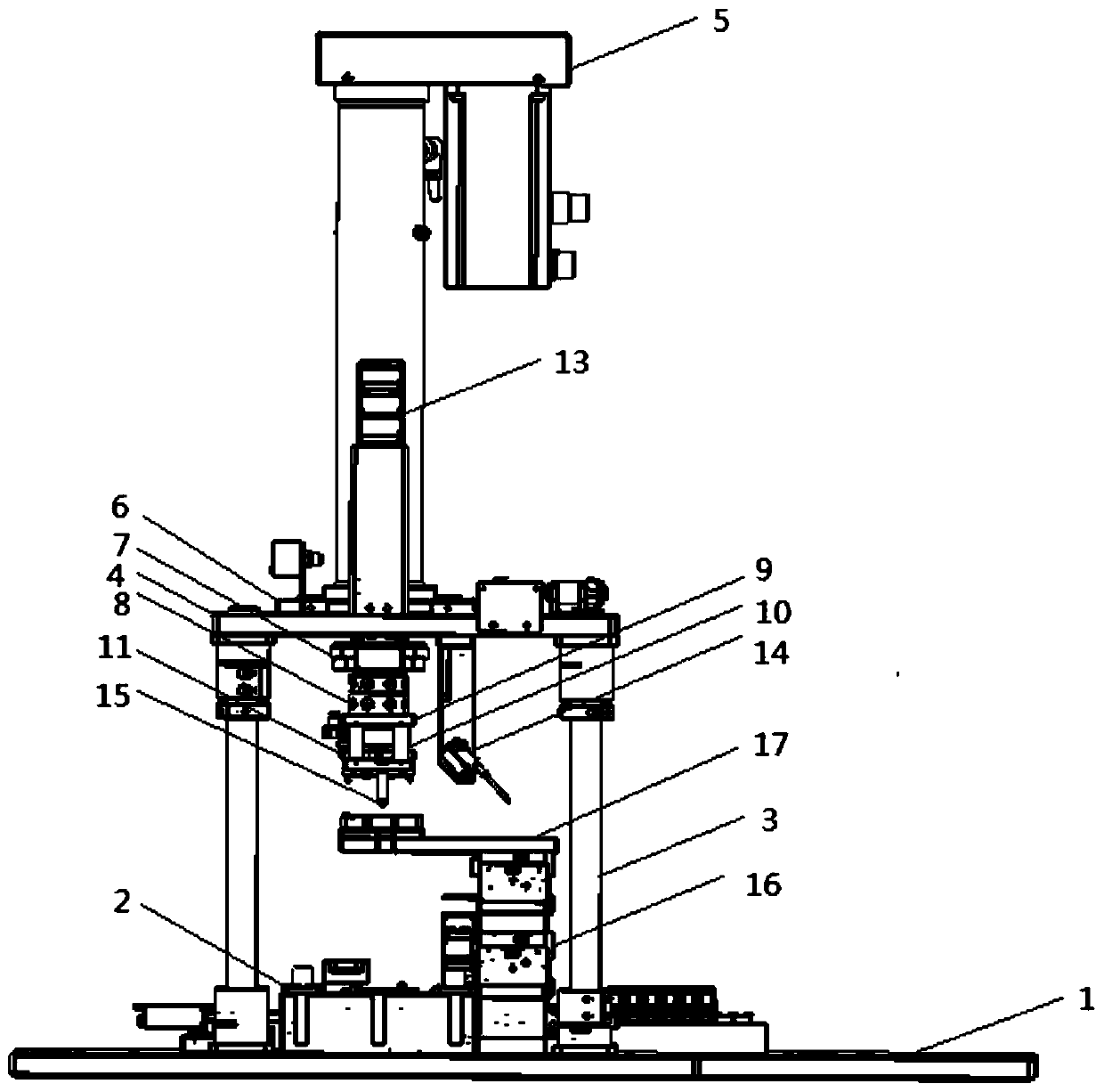

[0050] This embodiment mainly introduces the basic composition and connection relationship of a PCB board and PIN needle crimping device of the present invention.

[0051] like figure 1 As shown in , it shows a perspective view of a PCB board and PIN pin crimping device; figure 2 As shown, it shows a front view of a PCB board and PIN pin crimping device; as image 3 As shown in , it shows a left side view of a PCB board and PIN pin crimping device, such as Figure 4 As shown, it shows a top view of a PCB board and PIN pin crimping device.

[0052] to combine figure 1 , 2 As shown in , 3 and 4, a PCB board and PIN pin crimping device provided in the embodiment of the present application, the device includes a support unit, a power unit and a transmission unit, and the structure of the support unit is a bracket with a base 1 , used to carry the power unit and the transmission unit, the power unit and the transmission unit are located on the bracket, the power unit is conne...

Embodiment 2

[0069] On the basis of Embodiment 1, this embodiment further proposes a method for using a PCB board and PIN pin crimping device, and the same technical features and technical descriptions as Embodiment 1 will not be repeated in this embodiment.

[0070] combine Figure 1~6 As shown, the method of using the PCB board and the PIN pin crimping device is as follows:

[0071] Step 1: Preliminary positioning is achieved by controlling the screw in and out of the adjustment screw on the press adjustment plate 6, and adjust the position of the servo press 5 in the horizontal direction, the purpose of which is to make the PCB board clamp the module and set it below it The axis of symmetry of the pallet 2 in the vertical direction basically coincides;

[0072] Step 2: The pneumatic module 16 transferred by the PCB carrier is connected to the cylinder (not shown in the figure) through the air pipe, the solenoid valve 19 sends a signal to control the communication of the air circuit, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com