Compression injection moulding method and device for preforms

A technology of compression pressing and semi-finished products, which is applied in the field of mold compression and die-casting semi-finished products, can solve the problem of troublesome plates with multiple activities, and achieve the effect of shortening the dosage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

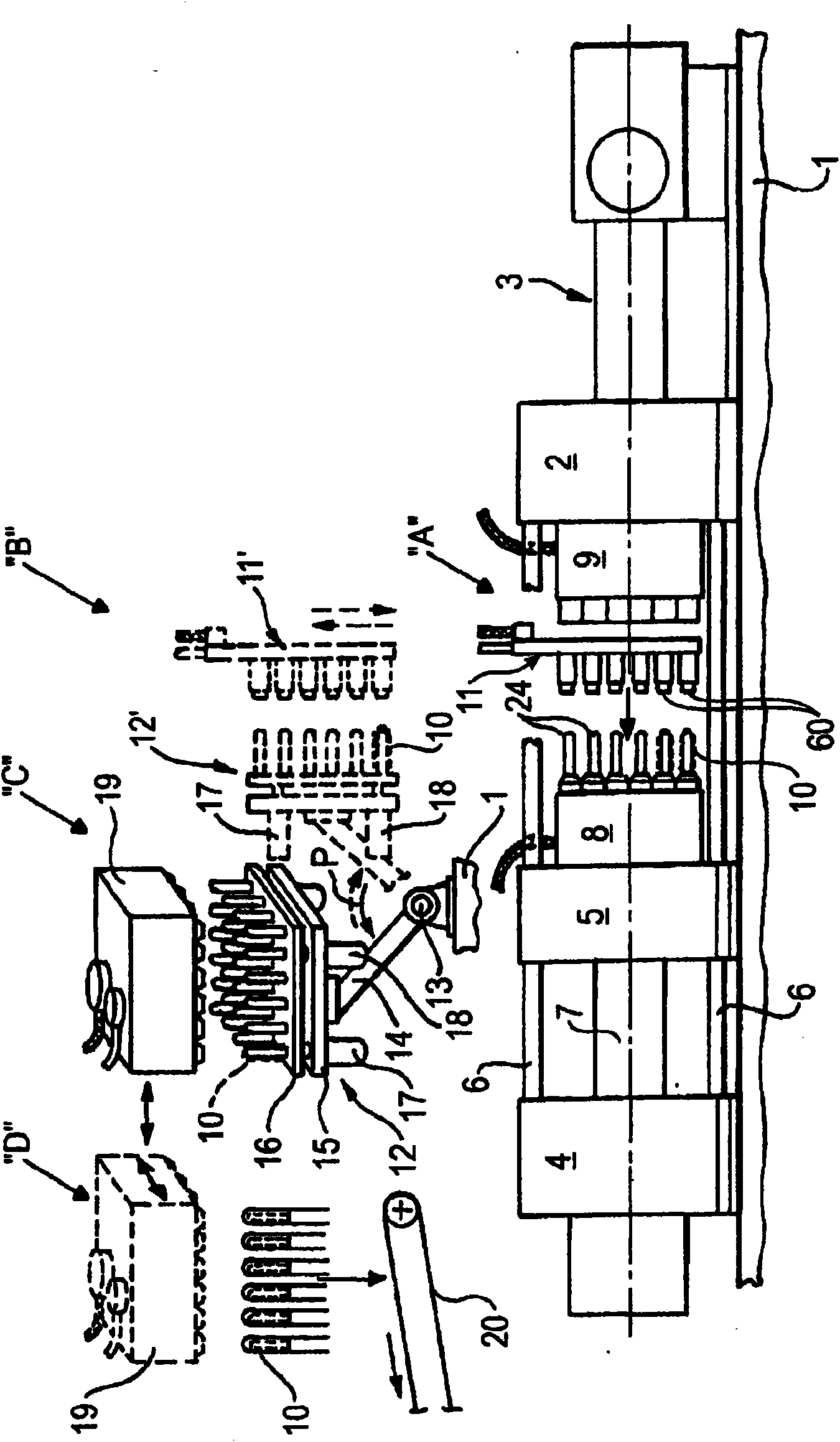

[0052] figure 1 A complete die-casting machine of the prior art for processing semi-finished products 10 is shown, with a bed 1 on which a fixed mold support plate 2 and an injection unit 3 as well as a support plate 4 are supported. The movable mold supporting plate 5 is supported on the bed 1 so as to move axially. The fixed mold support plate 2 and the support plate 4 are connected to each other by four cross members 6 which are guided through the movable mold support plate 5 . Between the support plate 4 and the movable mold support plate 5 there is a drive unit 7 for generating the closing movement and the closing pressure. The stationary mold support plate 2 and the movable mold support plate 5 support the mold halves 8 and 9, respectively, in which a plurality of mold cores 24 and mold cavities 60 are arranged respectively, which together form mold nests for producing a corresponding number of sleeve die castings part. After the mold halves 8 and 9 have been opened, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com