Moving oil particle microscopic imaging system with double fiber-coupling LED light sources

A micro-imaging and fiber-optic coupling technology, applied in the testing of moving fluids/granular solids, optical devices, color/spectral characteristics measurement, etc., can solve the problem of ferrography analysis, which is difficult to obtain quantitative wear particle information, and difficult to detect oil Abrasive particles with a size larger than 10 microns, particle contamination detection cannot be used to monitor wear status and other issues, so as to improve stability and service life

Inactive Publication Date: 2011-01-12

AERONAUTICAL EUIPMENT INST AIR EQUIP ACAD P L A

View PDF3 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, any of the above-mentioned individual monitoring methods cannot cover comprehensive fault symptom information. For example, spectral analysis is difficult to detect abrasive particles larger than 10 microns in oil, ferrographic analysis is difficult to obtain quantitative wear particle information, and particle pollution detection cannot be used for Monitor wear status

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

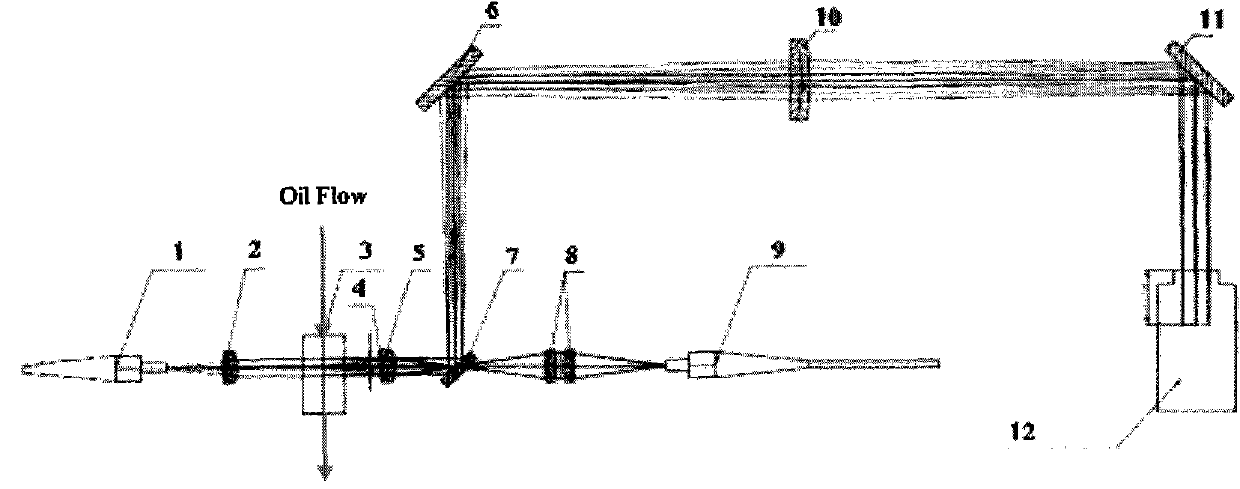

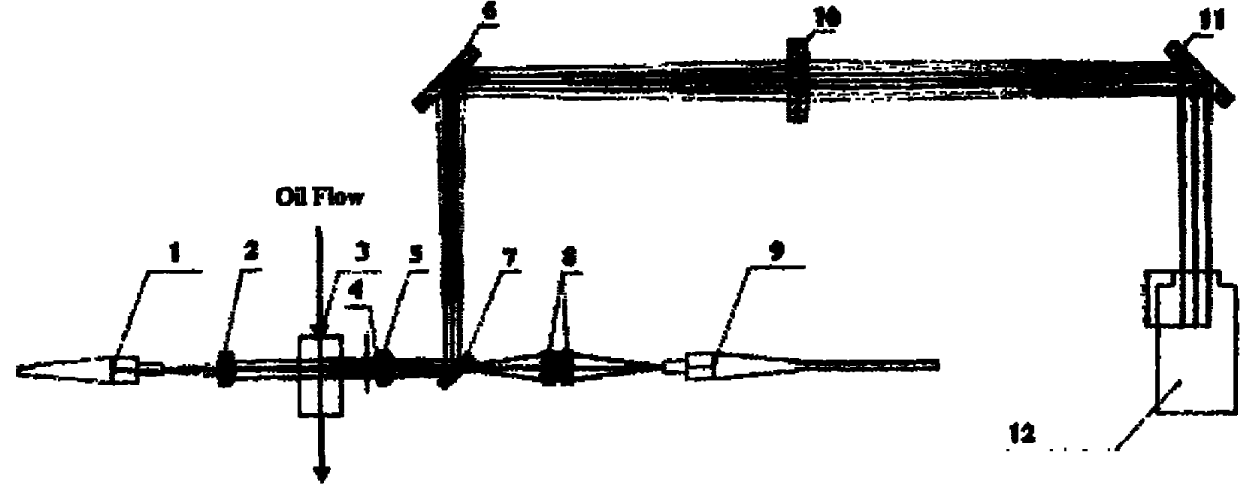

The invention relates to a photoelectric microscopic imaging system, which is used for acquiring the digital image information of moving particles in oil. The system is characterized by adopting double fiber-coupling LED-based transmission and reflecting light sources of two colors to optically amplify and image the moving particle objects in the flowing oil by a telephoto lens component and then acquire the digital image information, such as surface colors, profiles, sizes, porosity factors and the like, of the particle objects by a high-speed digital charge coupled device for analysis on the types, number and size distribution of the particles in the oil to further determine the mechanical wear condition and an oil particle pollution degree in a sealed oil oil-way system. The system is applied to mechanical condition monitoring and failure diagnosis in the fields of aviation, ships, railways and the like.

Description

technical field The invention relates to an optical microscopic imaging system for moving particles of oil through optical fiber coupling LED transflective double-color light sources, a telephoto lens assembly, a window-type flow cell and a high-speed digital CCD to obtain the moving particle target in the flowing oil. Digital image information such as surface color, contour, size and porosity is used to analyze the type, quantity and size distribution of particles in the oil, and then determine the mechanical wear state and solid particle pollution inside the closed oil system. It is suitable for aviation, Mechanical status monitoring and fault diagnosis in ships, railways and other fields. Background technique In the process of state monitoring and condition-based maintenance of equipment, it is necessary to carry out oil monitoring work on its internal closed lubrication system and hydraulic system. Oil monitoring is a modern maintenance technology that monitors the wear...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B11/00G01B11/24G01N15/08G01N21/25

CPCG01N15/1031G01N15/147G01N21/85G01N33/2858G01N2015/0053G01N2015/144

Inventor 陈立波王洪伟宋兰琪张占纲宋科

Owner AERONAUTICAL EUIPMENT INST AIR EQUIP ACAD P L A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com