Silent chain transmission device

A transmission device, silent chain technology, applied in the direction of transmission device, valve drive device, transmission chain, etc., can solve the problems of variable length, increased space occupation, increased weight of chain 920, etc., to reduce the number of parts and reduce the weight of the chain , reduce the effect of occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

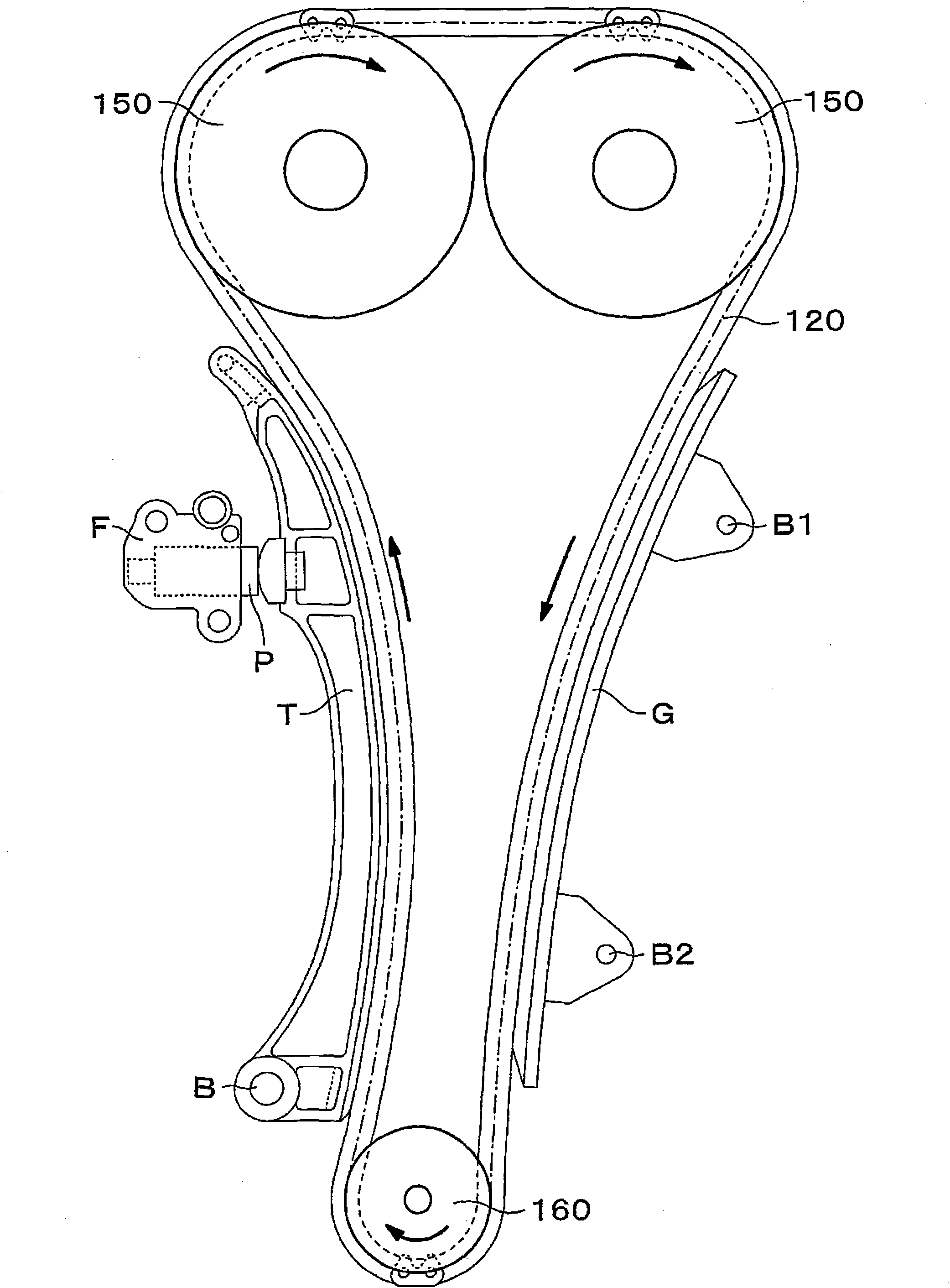

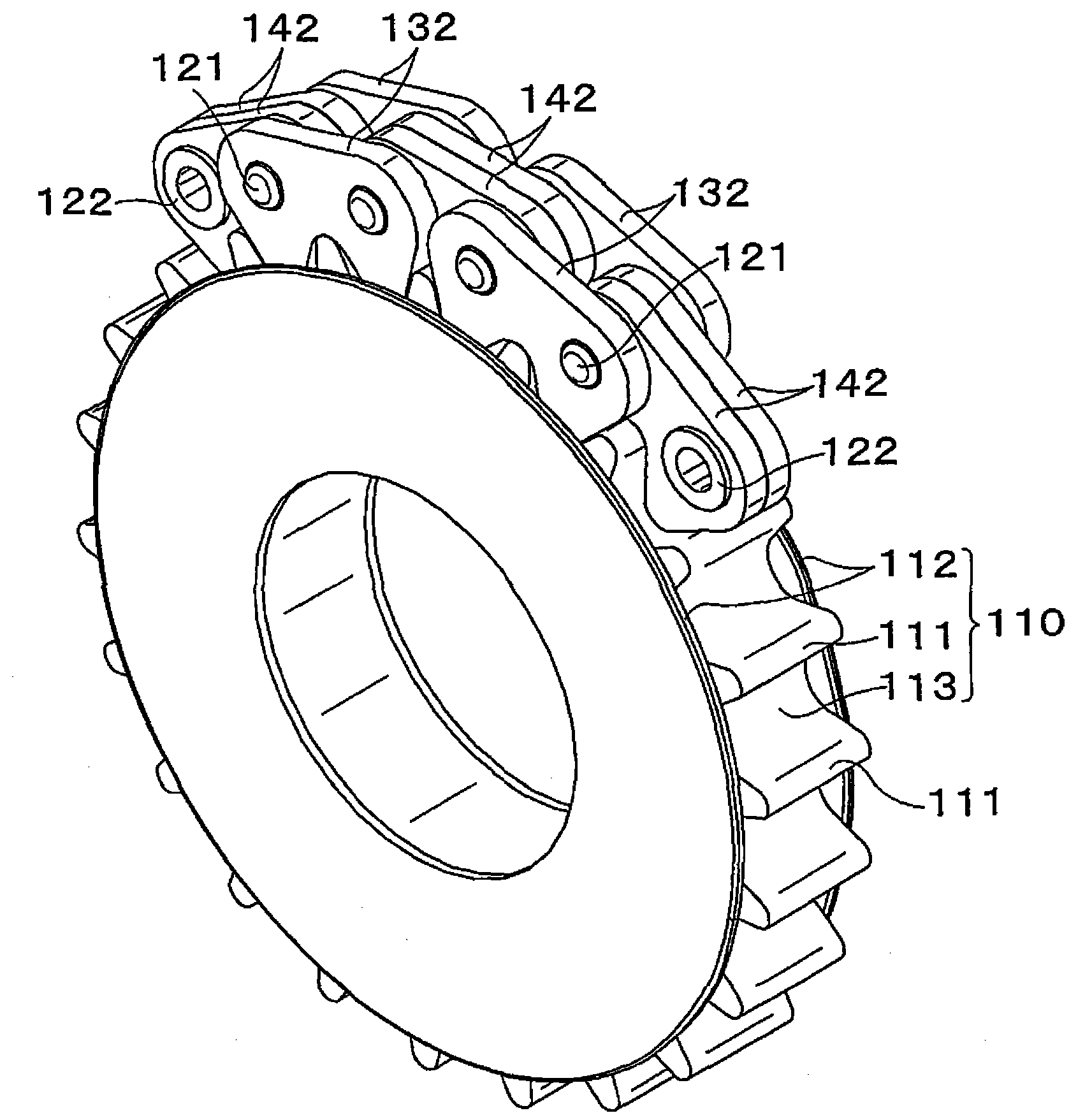

[0089] Such as Figure 2 to Figure 4As shown, the silent chain transmission 100 as the first embodiment of the present invention is composed of a chain 120 and a sprocket 110 (a driven sprocket 150 and a driving sprocket 160), and the above-mentioned chain 120 is composed of an outer chain link (a first chain link) row) and the inner chain link (the second chain link row) are alternately connected and woven through the connecting pin 121 and the bushing 122 so as to be able to bend. The sprocket 111 is provided on the outer peripheral surface, and the said convex part 112 guides the chain 120 on both outer sides of the sprocket 111. As shown in FIG.

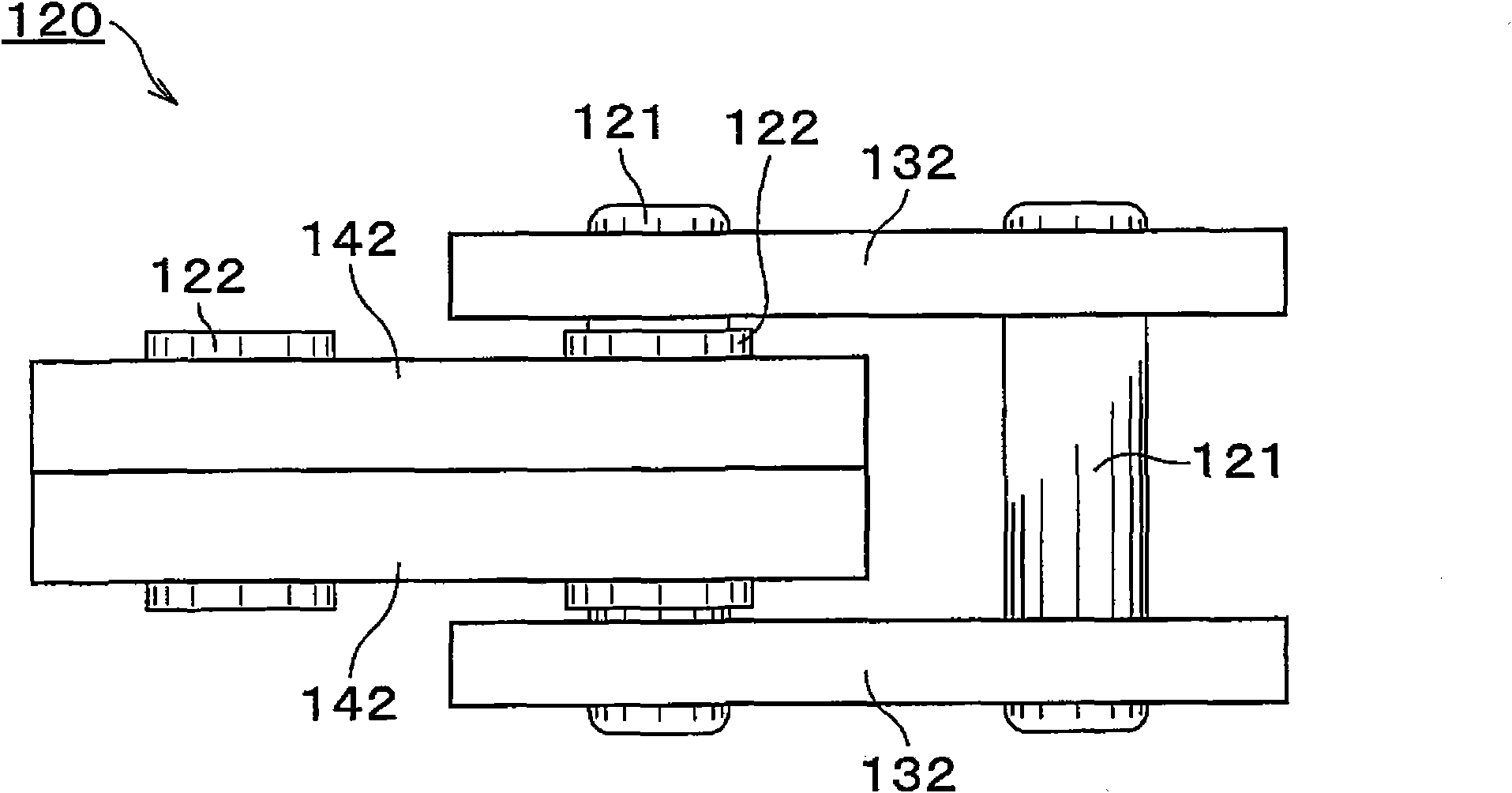

[0090] Such as image 3 , Figure 4 As shown, the chain 120 is composed of a first chain link row, that is, an outer chain link row, and a second chain link row, that is, an inner chain link row. The above-mentioned second link row is constituted by a pair of inner link plates 142 having a pair of front and rear sleeve holes 1...

Embodiment 2

[0097] For the silent chain drive 220 as the second embodiment of the present invention, as Figure 5 As shown, the hollow cylindrical bushing 222 is press-fitted into the bushing hole 243 of the inner link plate 242, and the pair of inner link plates 242 are spaced apart from each other.

[0098] Other structures of the silent chain transmission are the same as those of the first embodiment.

[0099] Therefore, by ensuring the sliding area of the connecting pin 221 and the bushing 222 and reducing the surface pressure, the bending resistance can be reduced to reduce noise and vibration, and it is not necessary to provide too many link plates, and it is not necessary to install the chain at the end of the chain 220. The outer side of the outer link plate 132 is provided with a guide plate for preventing disengagement, so the maximum width of the chain 220 can be narrowed, the number of parts can be reduced, and the weight of the chain 220 can be reduced, thereby reducing the...

Embodiment 3

[0101] Such as Image 6 , Figure 7 As shown, the silent chain transmission device 300 as the third embodiment of the present invention is composed of a chain 320 and a sprocket (the same as the first embodiment, not shown), and the chain 320 is composed of an outer chain link row (the first chain link row ) and the inner chain link row (the second chain link row) are alternately connected and knitted by connecting pins 321 to be able to bend, and the sprocket has a sprocket main body with sprocket teeth on the outer peripheral surface and a Lugs to guide the chain.

[0102] The chain 320 is composed of a first chain link row, that is, an outer chain link row, and a second chain link row, that is, an inner chain link row. The second link row consists of an inner link plate 342 having a front and rear pair of pin holes 343 .

[0103] The outer link plate 332 of the outer link row is provided with plate teeth 334, the connecting pin 321 is inserted through the pin hole 133 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com